Bi3YO6 inorganic pigment doped with iron/terbium element and preparation method and application thereof

A technology for inorganic pigments and iron elements, which is applied in the field of pigments to achieve the effects of simple preparation process, easy mass production and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

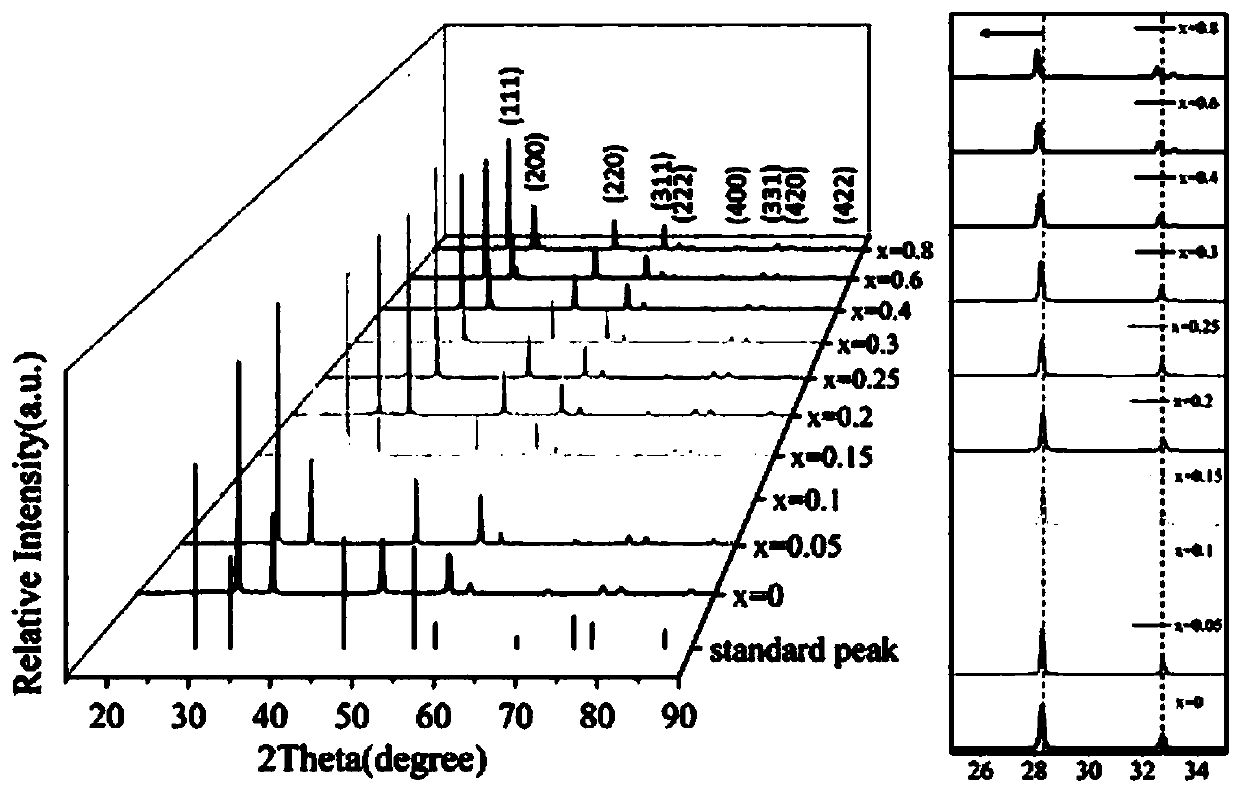

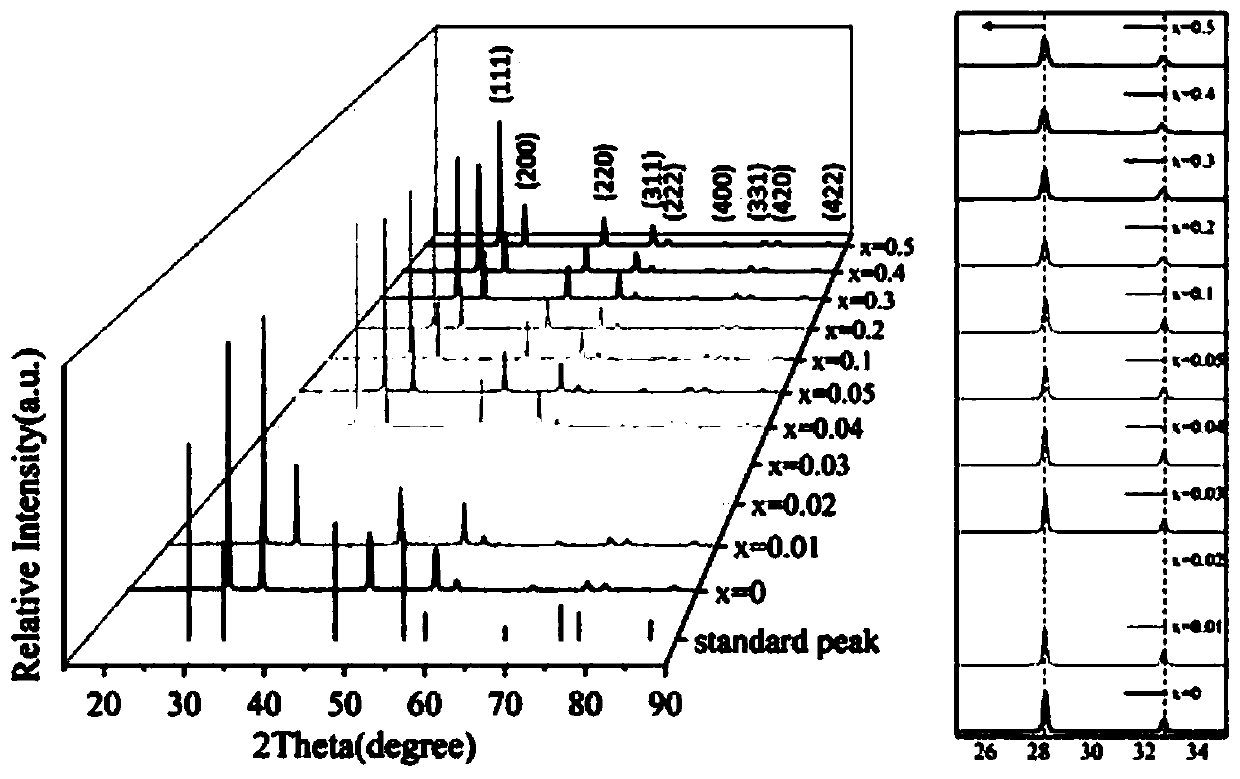

[0036] Bi above 3 YO 6 The preparation method of inorganic pigment is characterized in that, comprises the steps:

[0037] (1) Weigh the raw materials according to the amount, and the raw materials include Bi 2 o 3 , Y 2 o 3 And oxides that need doping elements, the oxides of doping elements are Fe 2 o 3 or Tb 4 o 7 ;

[0038] (2) The raw material that weighs is mixed acetone and grinds in agate mortar, after acetone volatilizes completely, obtains mixed powder;

[0039] (3) drying the mixed powder, and calcining the dried mixed powder;

[0040] (4) After the reaction in step (3) is completed, naturally cool to room temperature to obtain a pigment product.

[0041]Further, the calcination process is as follows: first react at 800°C for 90 minutes, and then heat to 900°C for 120 minutes.

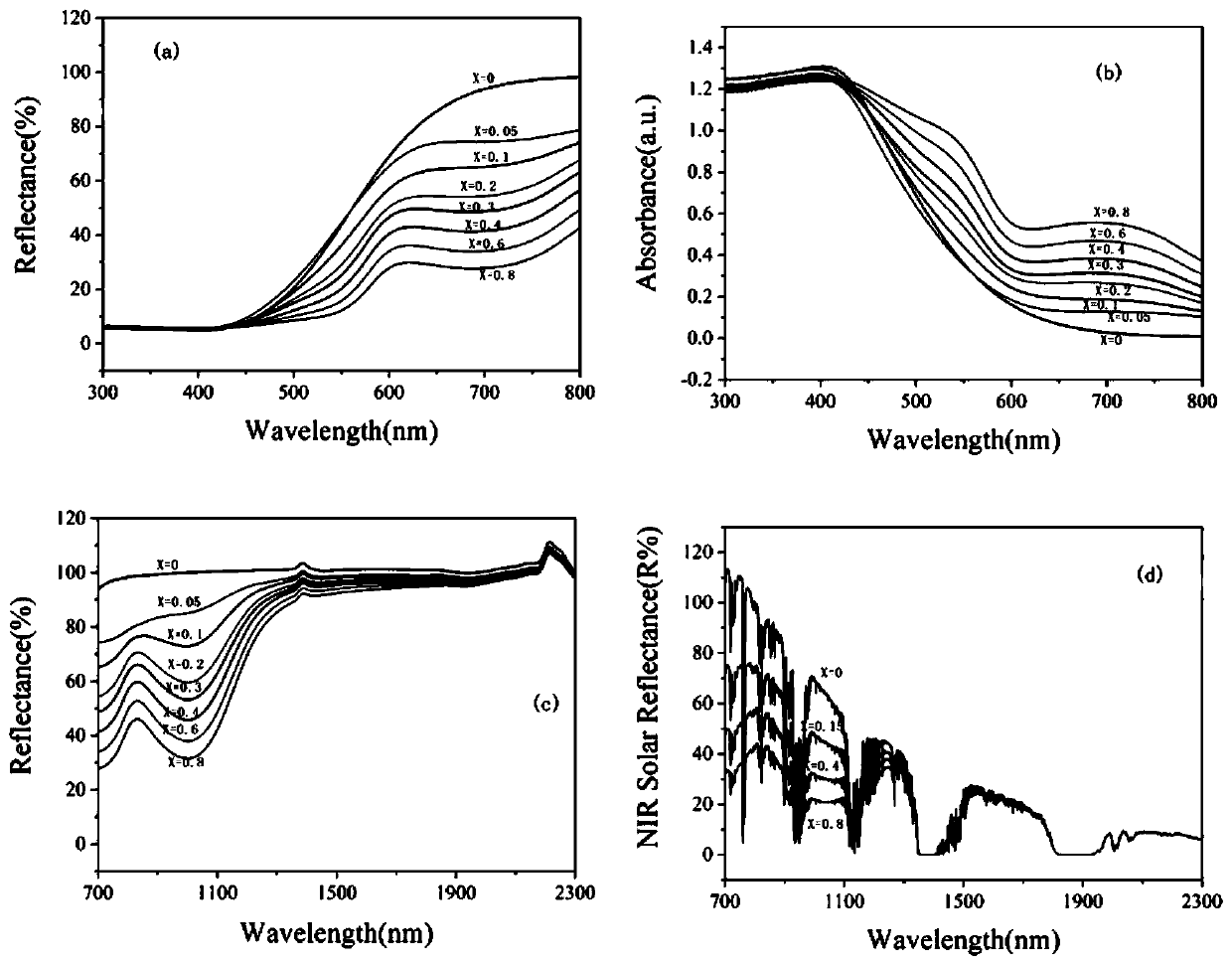

[0042] Bi mentioned above 3 YO 6 Application of inorganic pigments, the inorganic pigments are used for external painting of buildings or oil and gas storage tanks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com