Bio-based artificial aquatic plant

A kind of artificial aquatic plants, bio-based technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, textiles and paper making, etc., can solve the problems of unsolved degradation of artificial aquatic plants, cumbersome installation process of artificial aquatic plants, environmental pollution, etc. problems, to avoid rust or corrosion, improve the efficiency of installation and disassembly, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

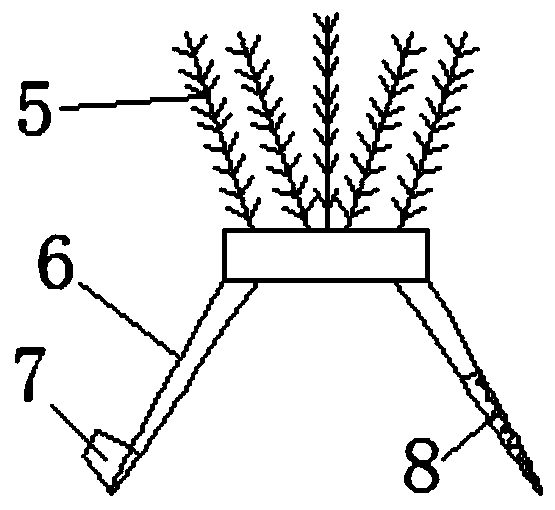

[0029] The above-mentioned water grass fiber 5 is composed of mesoporous activated carbon fibers prepared by mixing asphalt, starch plastic and α-methyl cellulose, and the mass ratio of the pitch, starch plastic and α-methyl cellulose is 4:2:4.

[0030] The preparation method of aquatic plant fiber 5 comprises the following steps:

[0031] (1) Add Y(CH 3 COCHCOCH 3 ) 3 .2H 2 O to obtain yttrium-containing pitch, dissolving starch plastics and α-methylcellulose in DMF to obtain a mixed solution of degradable polymer materials, and spinning out the mixed solution of yttrium-containing pitch and degradable polymer materials through dry jet wet spinning mixed fibers;

[0032] (2) Mesoporous activated carbon fibers were obtained from the mixed fibers through insolubilization, carbonization and activation. The carbonization conditions were as follows: in nitrogen flow, the temperature was raised to 900° C., and the heating rate was 10° C. / min.

Embodiment approach 2

[0034] The above-mentioned water grass fiber 5 is composed of mesoporous activated carbon fibers prepared by mixing asphalt, starch plastic and α-methyl cellulose, and the mass ratio of the pitch, starch plastic and α-methyl cellulose is 5:3:2.

[0035] The preparation method of aquatic plant fiber 5 comprises the following steps:

[0036] (1) Add Y(CH 3 COCHCOCH 3 ) 3 .2H 2 O to obtain yttrium-containing pitch, dissolving starch plastics and α-methylcellulose in DMF to obtain a mixed solution of degradable polymer materials, and spinning out the mixed solution of yttrium-containing pitch and degradable polymer materials through dry jet wet spinning mixed fibers;

[0037] (2) Mesoporous activated carbon fibers were obtained from the mixed fibers through insolubilization, carbonization and activation. The carbonization conditions were as follows: in a nitrogen flow, the temperature was raised to 950° C., and the heating rate was 10° C. / min.

Embodiment approach 3

[0039]The above-mentioned water grass fiber 5 is composed of mesoporous activated carbon fibers prepared by mixing asphalt, starch plastic and α-methylcellulose, and the mass ratio of the asphalt, starch plastic and α-methylcellulose is 6:3:1.

[0040] The preparation method of aquatic plant fiber 5 comprises the following steps:

[0041] (1) Add Y(CH 3 COCHCOCH 3 ) 3 .2H 2 O to obtain yttrium-containing pitch, dissolving starch plastics and α-methylcellulose in DMF to obtain a mixed solution of degradable polymer materials, and spinning out the mixed solution of yttrium-containing pitch and degradable polymer materials through dry jet wet spinning mixed fibers;

[0042] (2) Mesoporous activated carbon fibers were obtained from the mixed fibers through insolubilization, carbonization and activation. The carbonization conditions were as follows: in a nitrogen flow, the temperature was raised to 1000° C., and the heating rate was 10° C. / min.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap