Preparation method of polyolefin microporous breathable film

A polyolefin and breathable film technology, applied in the field of preparation of polyolefin microporous breathable films, can solve the problems of reducing the usage of plastic products and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

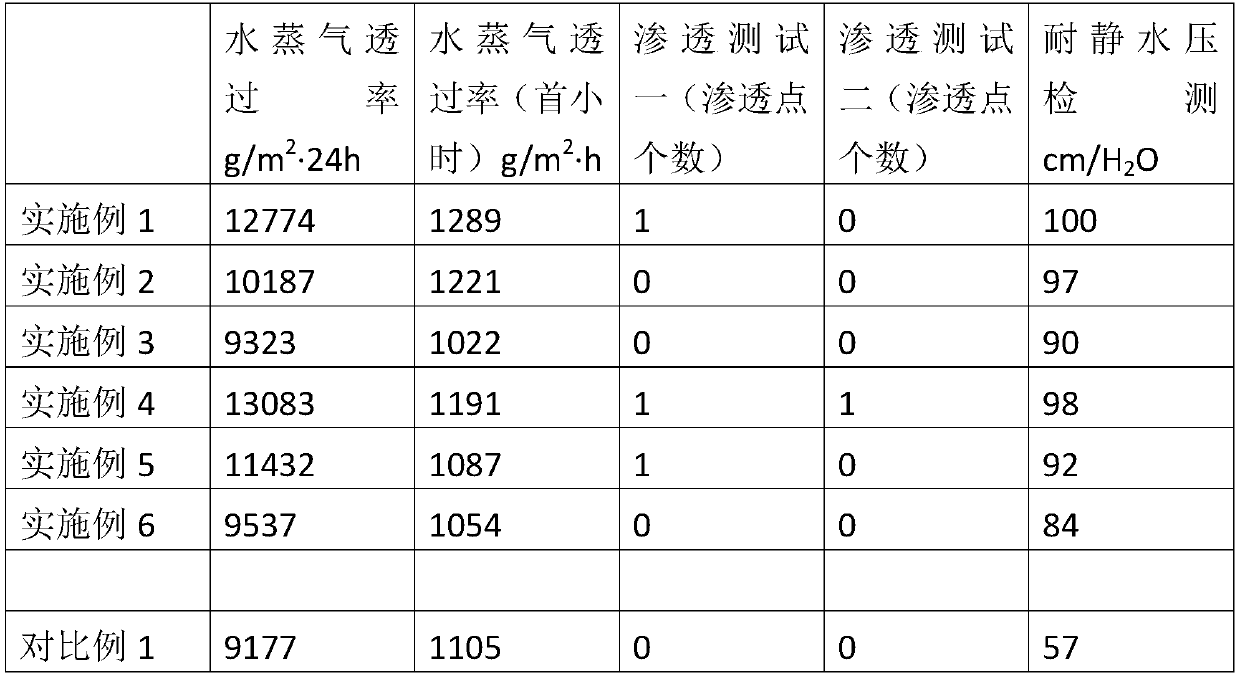

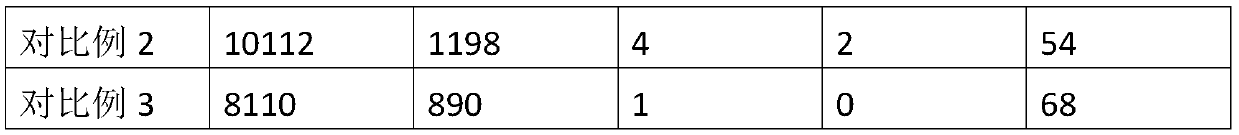

Examples

Embodiment 1-3

[0021] The preparation process of the polyolefin microporous air-permeable membrane of the present embodiment is as follows:

[0022] Step 1), blending and extruding: mixing the polyolefin base material and the inorganic filler according to a weight ratio of 1:1, obtaining a composite material through a blending and extrusion process, and obtaining composite material particles through a granulation process;

[0023] The polyolefin substrate used in Examples 1-3 is a mixture of metallocene polyethylene and linear low-density polyethylene in a weight ratio of 1:1; wherein, the melt index of metallocene polyethylene is 1.3g / 10min, and the density is 0.927g / cm 3 , is the Exceed series product that is purchased from Exxon Company; The melt index of linear low density polyethylene is 1.0g / 10min, and density is 0.930g / cm 3 , is the DOWLEX series product purchased from DOW Company;

[0024] The inorganic filler used in Examples 1-3 is a mixture of calcium carbonate and titanium dio...

Embodiment 1

[0028] Example 1, in the above step 3), the draw ratio is about 5.5, and the obtained basis weight is a microporous air-permeable membrane of 10gsm;

Embodiment 2

[0029] Embodiment 2, in the above step 3), the draw ratio is about 4.5, and the obtained basis weight is a microporous air-permeable membrane of 12gsm;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com