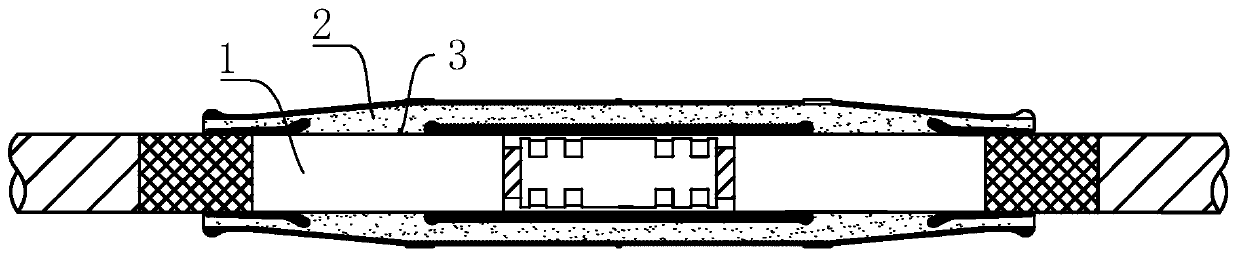

Connection sealing structure of electric transmission line and application

A sealing structure and electrical transmission technology, applied in the direction of conductive connection, electrical component connection, connection, etc., can solve the problems of affecting the sealing effect of the intermediate connector, poor peeling construction of the electrical transmission line, untreated smooth surface, etc., to achieve excellent anti-fouling. Flashing, good waterproof performance, the effect of avoiding air gap defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

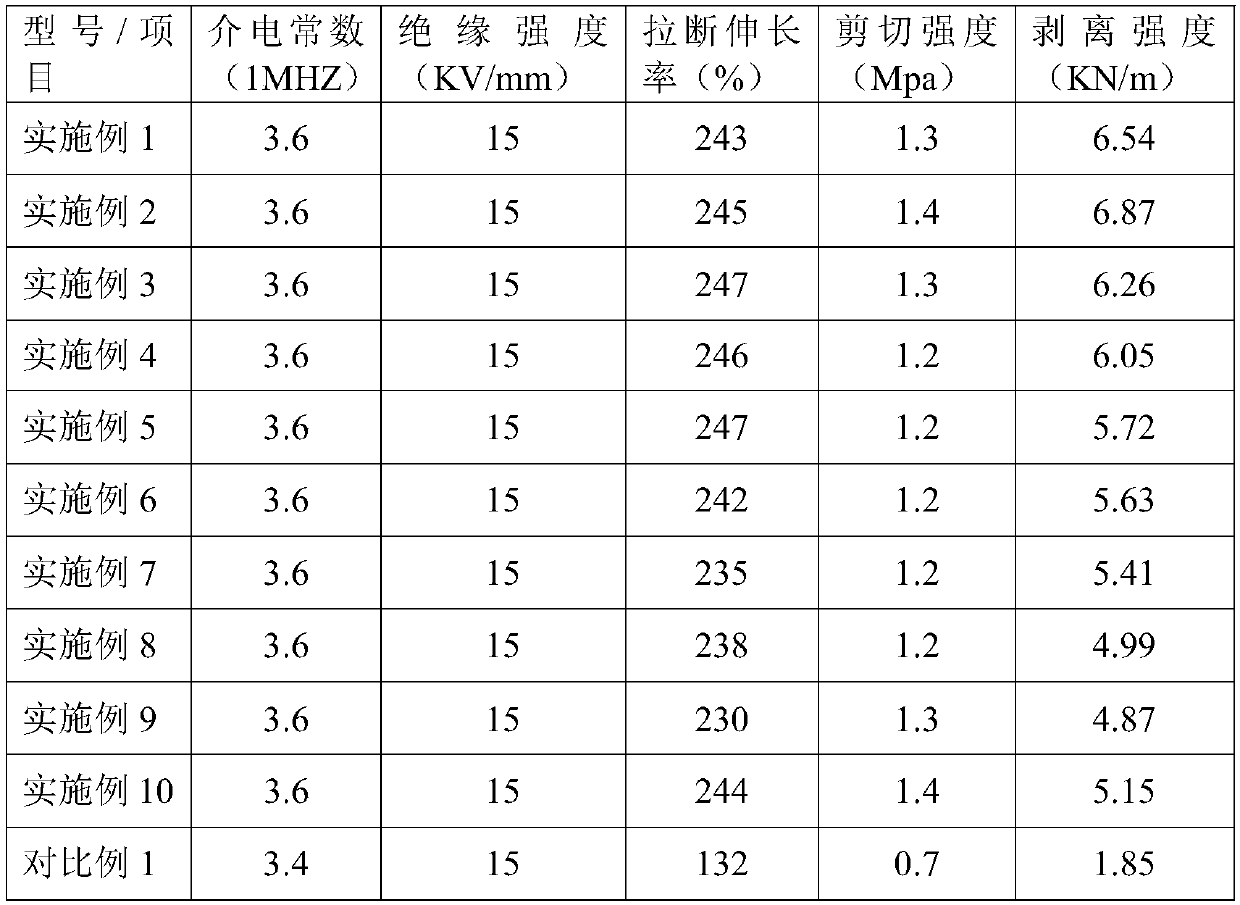

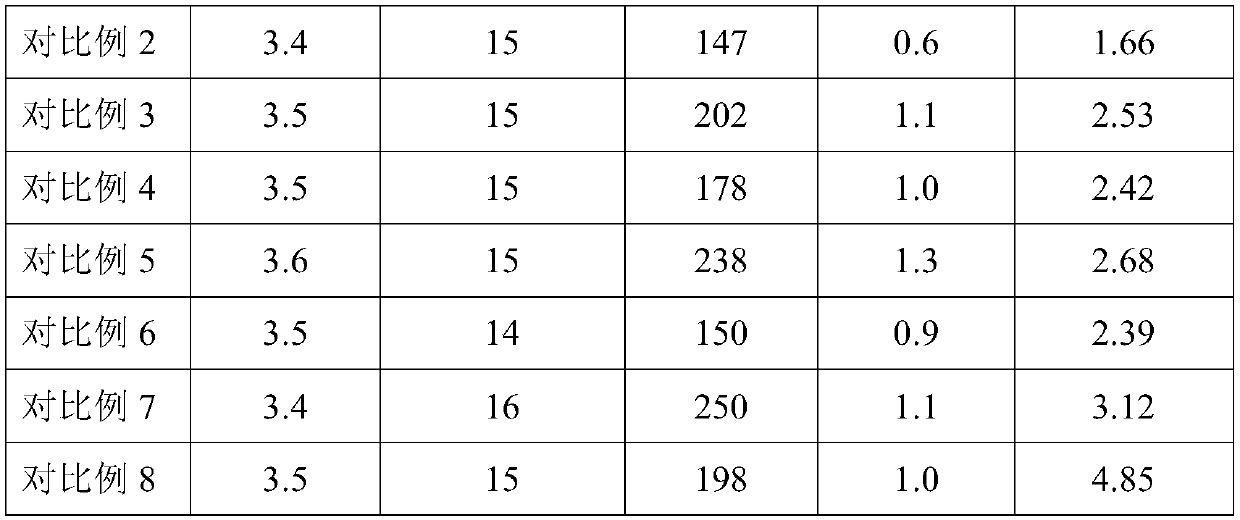

Examples

Embodiment 1

[0041] An adhesive of cross-linked polyethylene and silicone rubber, comprising A and B, wherein,

[0042] A comprises the following components by weight:

[0043] 100 parts of hydroxyl silicone oil, 10 parts of basic crosslinking agent, 10 parts of additional crosslinking agent and 5 parts of hydrophobic fumed silica;

[0044]The basic crosslinking agent consists of 2 parts of methyltrimethoxysilane, 2 parts of methyltriethoxysilane, 2 parts of vinyltrimethoxysilane, 2 parts of vinyltriethoxysilane, 2 parts of Composed of phenyltrimethoxysilane; additional crosslinking agent consists of 2 parts of isocyanatopropyltriethoxysilane, 2 parts of vinyltriisopropenoxysilane, 2 parts of methyltriisopropenoxysilane , 2 parts of phenyl triisopropenyloxysilane, 2 parts of tetramethylguanidinopropyl trimethoxysilane;

[0045] B comprises the following components by weight:

[0046] 100 parts of hydroxy silicone oil, 5 parts of hydrophobic fumed silica and 0.2 part of catalyst;

[004...

Embodiment 2

[0050] An adhesive of cross-linked polyethylene and silicone rubber, comprising A and B, wherein,

[0051] A comprises the following components by weight:

[0052] 100 parts of hydroxyl silicone oil, 20 parts of basic crosslinking agent, 20 parts of additional crosslinking agent and 10 parts of hydrophobic fumed silica;

[0053] The basic crosslinking agent consists of 4 parts of methyltrimethoxysilane, 4 parts of methyltriethoxysilane, 4 parts of vinyltrimethoxysilane, 4 parts of vinyltriethoxysilane, 4 parts of Composed of phenyltrimethoxysilane; additional crosslinking agent consists of 4 parts of isocyanatopropyltriethoxysilane, 4 parts of vinyltriisopropenoxysilane, 4 parts of methyltriisopropenoxysilane , 4 parts of phenyl triisopropenyloxysilane, 4 parts of tetramethylguanidinopropyl trimethoxysilane;

[0054] B comprises the following components by weight:

[0055] 100 parts of hydroxy silicone oil, 10 parts of hydrophobic fumed silica and 0.3 part of catalyst;

[...

Embodiment 3

[0059] An adhesive of cross-linked polyethylene and silicone rubber, comprising A and B, wherein,

[0060] A comprises the following components by weight:

[0061] 100 parts of hydroxyl silicone oil, 25 parts of basic crosslinking agent, 30 parts of additional crosslinking agent and 15 parts of hydrophobic fumed silica;

[0062] The basic crosslinking agent consists of 5 parts of methyltrimethoxysilane, 5 parts of methyltriethoxysilane, 5 parts of vinyltrimethoxysilane, 5 parts of vinyltriethoxysilane, 5 parts of Composed of phenyltrimethoxysilane; the additional crosslinking agent consists of 6 parts of isocyanatopropyltriethoxysilane, 6 parts of vinyltriisopropenoxysilane, 6 parts of methyltriisopropenoxysilane , 6 parts of phenyl triisopropenyloxysilane, 6 parts of tetramethylguanidinopropyl trimethoxysilane;

[0063] B comprises the following components by weight:

[0064] 100 parts of hydroxy silicone oil, 15 parts of hydrophobic fumed silica and 0.5 part of catalyst; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com