Method for improving reliability of rubber and metal composite electric contact

A rubber-to-metal and electrical contact technology, applied in the field of materials or polymer materials, can solve the problems of metal layer falling off, inability to achieve firm bonding, personal safety accidents, etc., and achieve reliable bonding strength, good application prospects, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

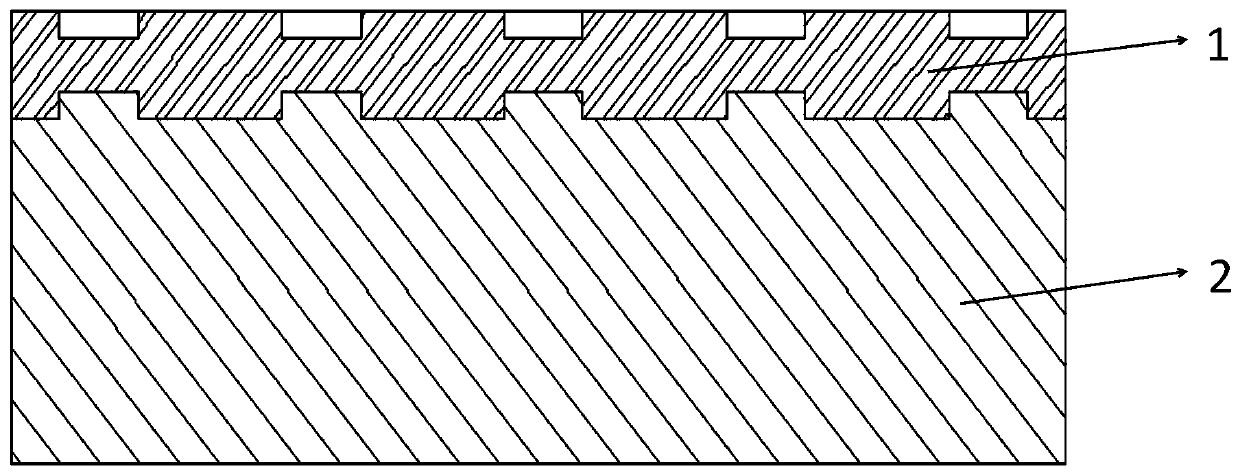

[0024] Clean the 0.08mm thick stainless steel sheet, and remove the oil on the surface of the sheet as much as possible. By laser etching, a plurality of pits with a diameter of 0.25mm are laser etched on both surfaces of the stainless steel sheet. The shape of the pits is cylindrical, and the depth of the pits is 0.030±0.005mm. The distance between the axes of two adjacent pits is 0.75mm. After the stainless steel sheet is dip-coated with a primer that promotes adhesion to silicone rubber, it is mixed with 0.5% 2,5-dimethyl-2,5-bis(tert-butyl peroxide) at about 165°C. base) Methyl vinyl silicone rubber of hexane was molded for 10 minutes, and the silicone rubber and the stainless steel sheet were bonded together to form a 0.85mm thick silicone rubber-stainless steel sheet.

[0025] Die the obtained silicone rubber-stainless steel sheet into small discs with a diameter of 3.5 mm to obtain a rubber-metal composite electrical contact. Due to the existence of pits, the outer su...

Embodiment 2

[0027] It is basically the same as that of Example 1, but the depths of the pits etched by laser on both sides of the stainless steel are different. During laser etching, the depth of the cylindrical pit etched on one surface of the stainless steel is 0.03-0.05mm, and the depth of the pit etched on the other surface of the stainless steel is 0.001-0.01mm. The side with a pit depth of 0.03-0.05mm will be exposed in the rubber-stainless steel sheet to form the outer surface of the composite sheet, while the side with a pit depth of 0.001-0.01mm will become the inner surface combined with silicone rubber.

[0028] The rubber-metal composite electrical contact prepared by this method has good dust resistance, and at the same time, because the laser etching depth of the inner surface of the metal layer is small, it is beneficial to shorten the laser etching time and improve production efficiency.

Embodiment 3

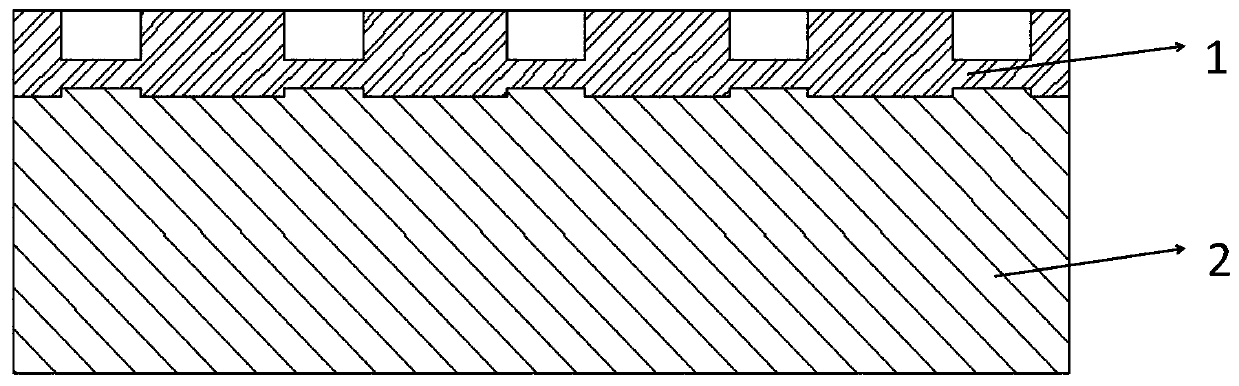

[0030] Design the pattern for exposure first. Clean the 0.10mm thick nickel sheet with a nickel content greater than 99.5%, and then use metal screen printing on both sides of the nickel sheet to print a photosensitive adhesive with a film thickness of 3-9μm that can be washed off with lye after curing , drying, exposure according to the designed pattern, and development (that is, washing off the photosensitive adhesive on the unexposed part with water), so that both sides are covered by the cured photosensitive adhesive film, but there are exposed evenly distributed metals (that is, Nickel) Nickel sheet with small dots. The diameter of the small metal dots is 0.2 mm, and the distance between the centers of two adjacent metal dots is 0.65 mm.

[0031] Etch the above nickel sheet protected by the photosensitive adhesive with an acid etching solution containing ferric chloride or copper chloride, etch the exposed metal dots on the nickel sheet protected by the photosensitive ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com