Manufacturing method of mold for 3D printing of sand mold

A 3D printing and manufacturing method technology, applied in the field of mold manufacturing, can solve the problems that cannot meet the production needs of small batches and rapid trial production, the weight of metal molds, and the high cost of mold manufacturing, so as to save casting and processing links, hanging The effect of convenient transportation and strong structural adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail through the drawings and examples below. Through these descriptions, the features and advantages of the present invention will become more apparent.

[0020] According to the first aspect of the present invention, the present invention provides a method for manufacturing a mold for 3D printing sand molds, the manufacturing method comprising the following steps:

[0021] Step (1), carry out three-dimensional design to mold, adopt sand mold 3D printer to prepare mold;

[0022] In step (2), the printed sand mold is infiltrated with a reinforcing liquid;

[0023] In step (3), the mold is subjected to numerical control cutting processing to obtain a qualified mold.

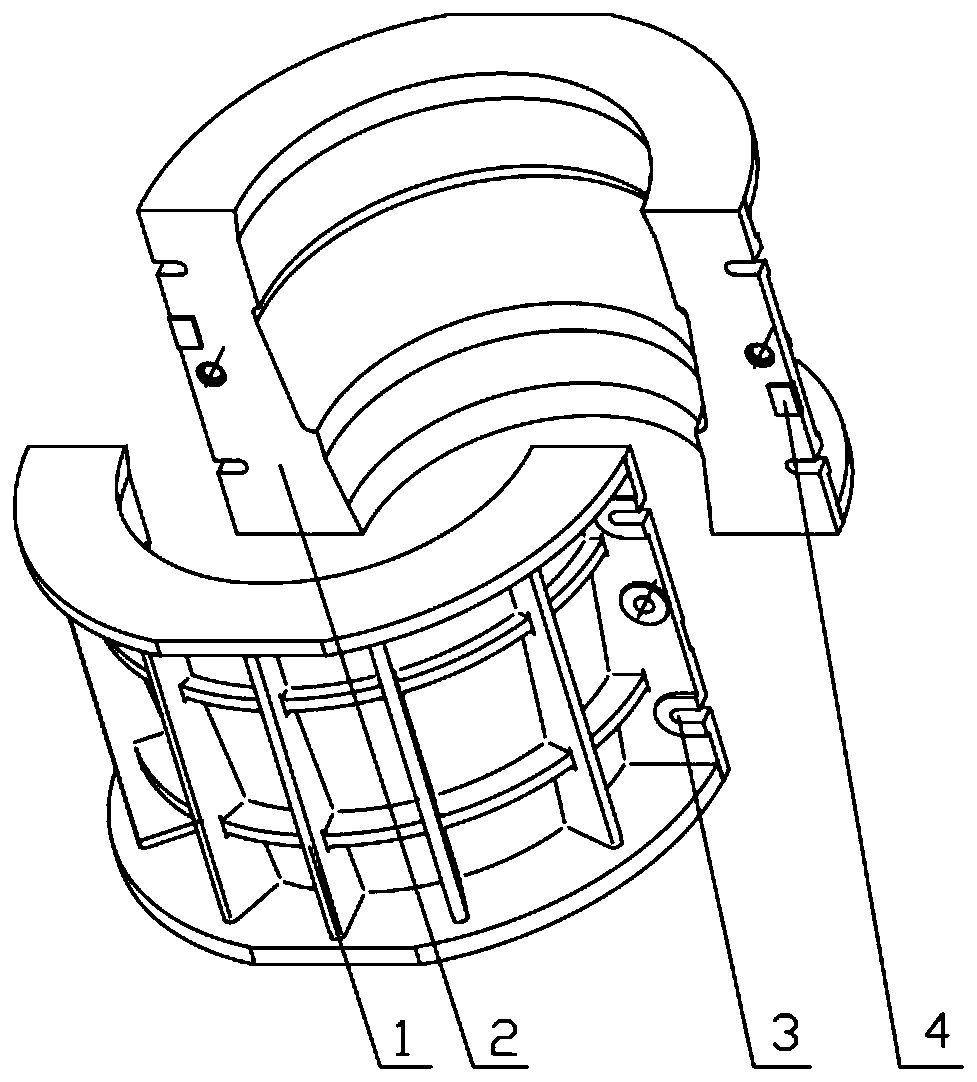

[0024] In step 1, the three-dimensional design of the mold is carried out by software such as CAD, and the mold can have a rib support structure 1, such as figure 1 shown.

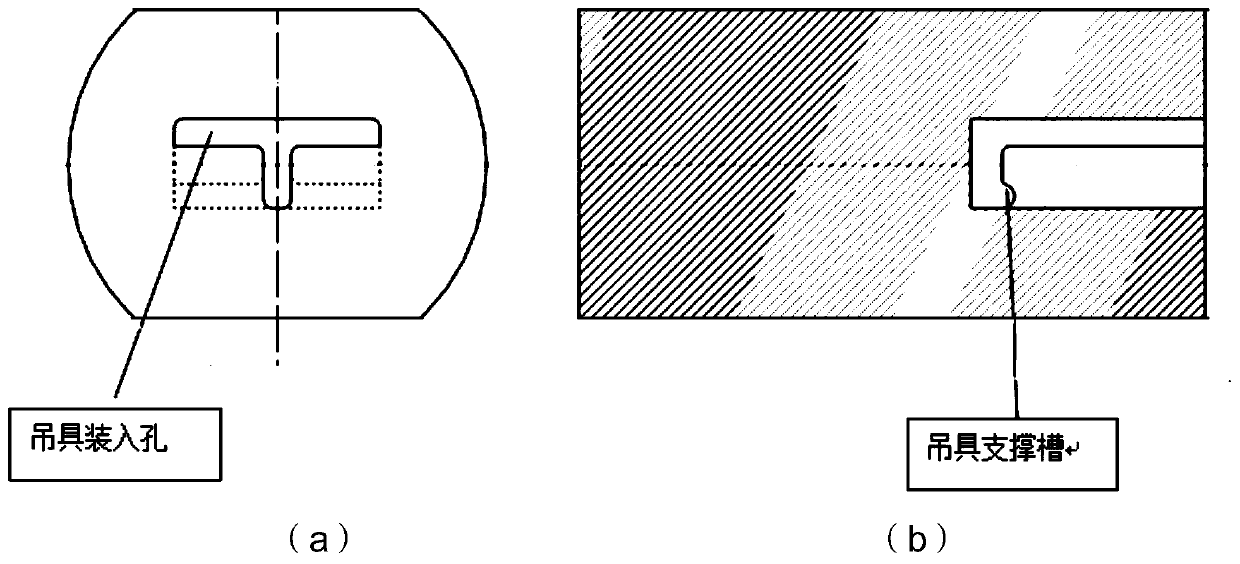

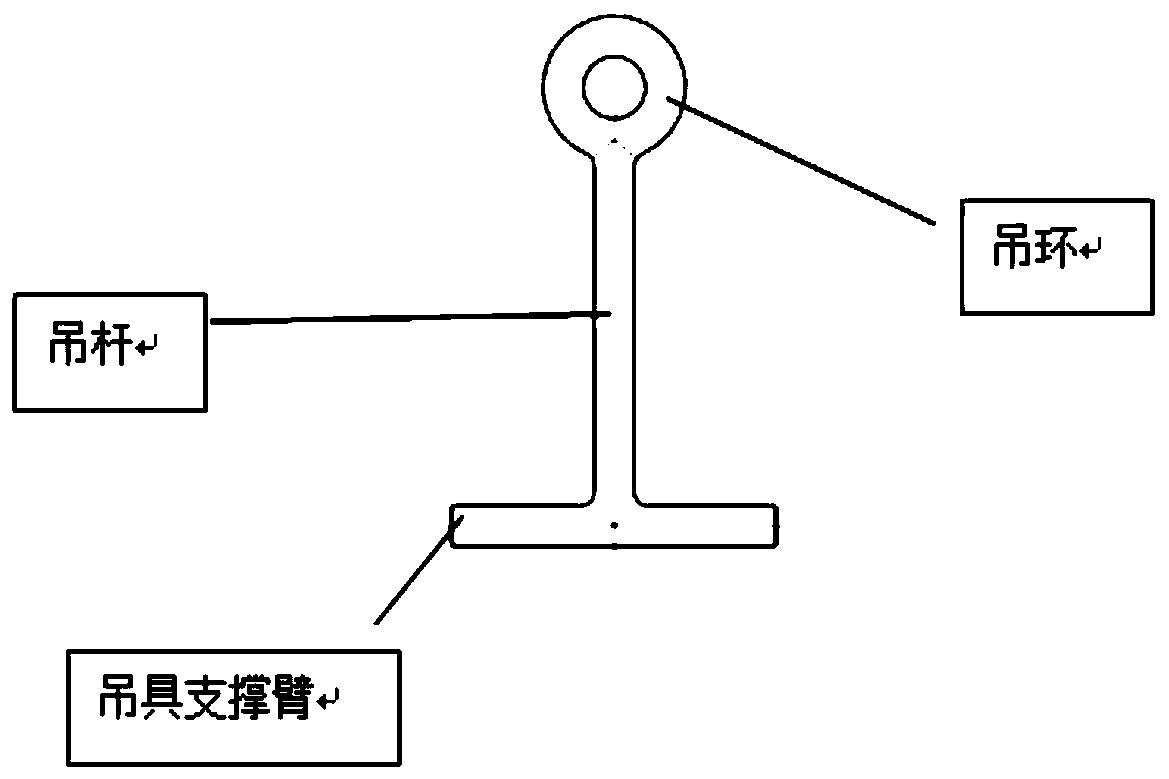

[0025] If the mold is assembled and combined with two split structures, two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com