System for recovering effective components in styrene byproduct tar

A technology for effective components and recovery systems, applied in organic chemistry, distillation purification/separation, aliphatic-aliphatic chain cracking of polyaryl-substituted aliphatic compounds to produce hydrocarbons, etc., can solve the problem of energy consumption and recovery of active components Problems such as large material loss, to achieve the effect of reducing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

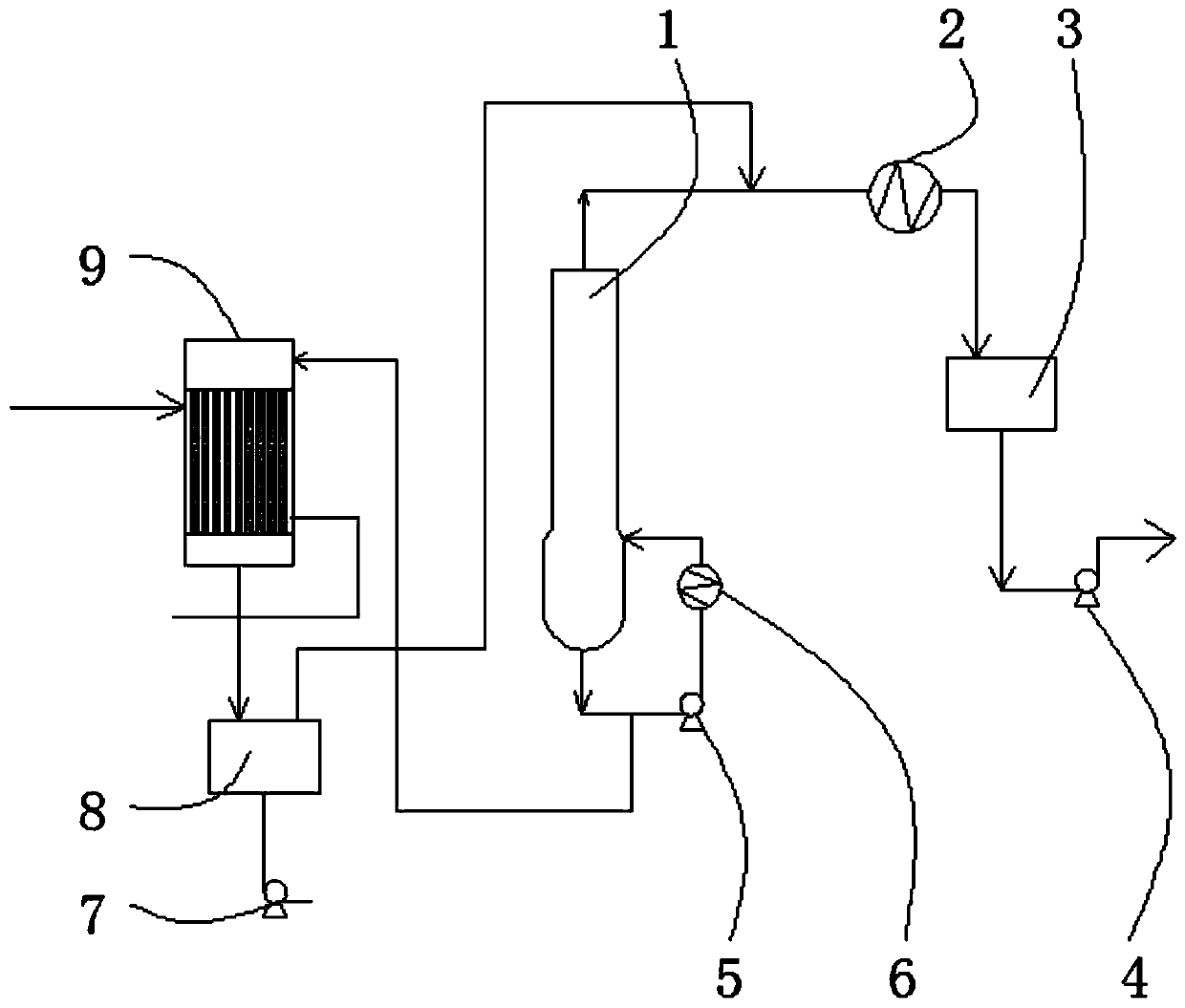

[0039] Please refer to figure 1 ,in, figure 1 A system flow diagram of a preferred embodiment of the system for recovering effective components in the styrene by-product tar provided by the present invention. A recovery system for effective components in styrene by-product tar, including:

[0040] Distillation tower 1;

[0041] A tower top condenser 2, which is communicated with the top of the rectifying tower 1 through a transfer pipe;

[0042] A recovery tank 3, the recovery tank 3 communicates with the output end of the overhead condenser 2 through a connecting pipe, and one side of the recovery tank 3 communicates with the input end of the recovery pump 4 through a feeding pipe;

[0043] A tower still pump 5, the input end of the tower still pump 5 is communicated with the bottom end of the rectifying tower 1 through a connecting pipe;

[0044] Reboiler 6, the input end of said reboiler 6 communicates with one side of said rectifying tower 1 through connecting pipe;

...

no. 2 example

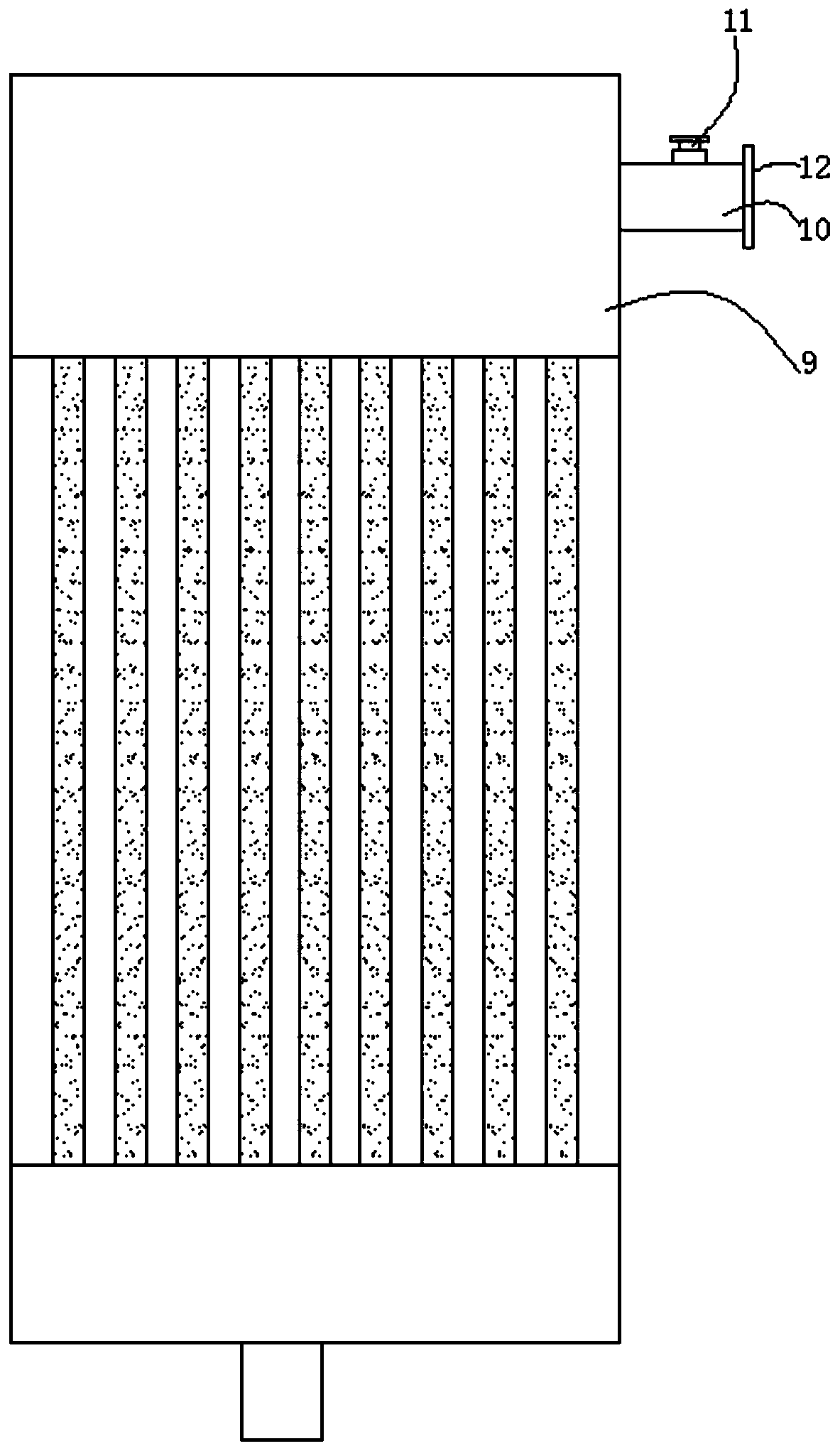

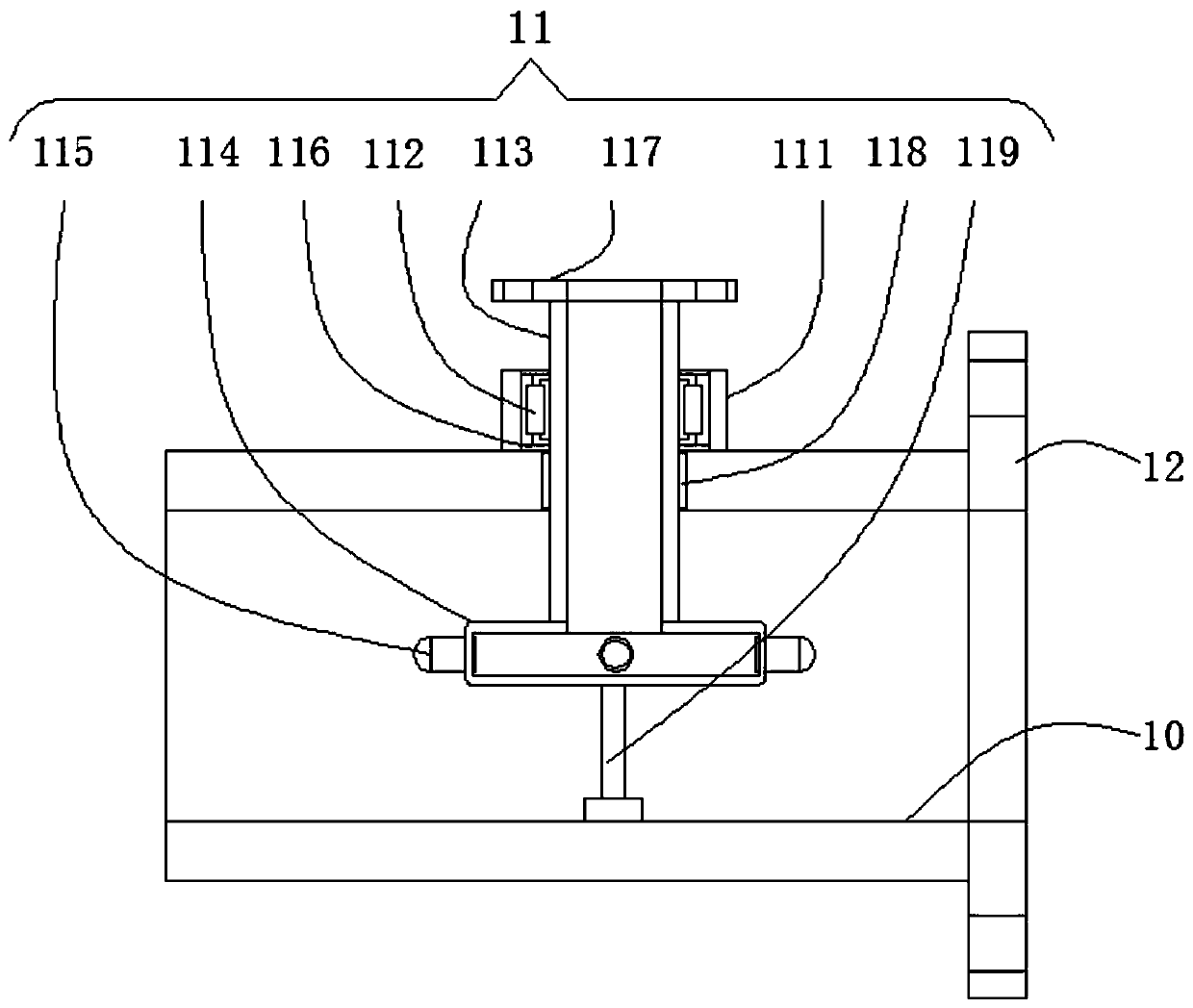

[0074] Please refer to figure 2 , image 3 with Figure 4 , Based on the system for recovering effective components in styrene by-product tar provided in the first embodiment of the present application, the second embodiment of the present application proposes another system for recovering effective components in styrene by-product tar. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0075] Specifically, the difference between the effective component recovery system used in the styrene by-product tar provided by the second embodiment of the present application is that it is used in the effective component recovery system in the styrene by-product tar, and the cracking reactor One side of 9 is communicated with a liquid inlet pipe 10, and the liquid inlet pipe 10 is provided with a rotating assembly 11, and the rotating assembly 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com