Patents

Literature

31results about "Hydrocarbon by polyarylsubstituted aliphatic compound split-off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid-acid isomerization catalyst and process

ActiveUS7041866B1Improve performanceImprove stabilityHydrocarbon by isomerisationCatalytic crackingAlkaneSulfation

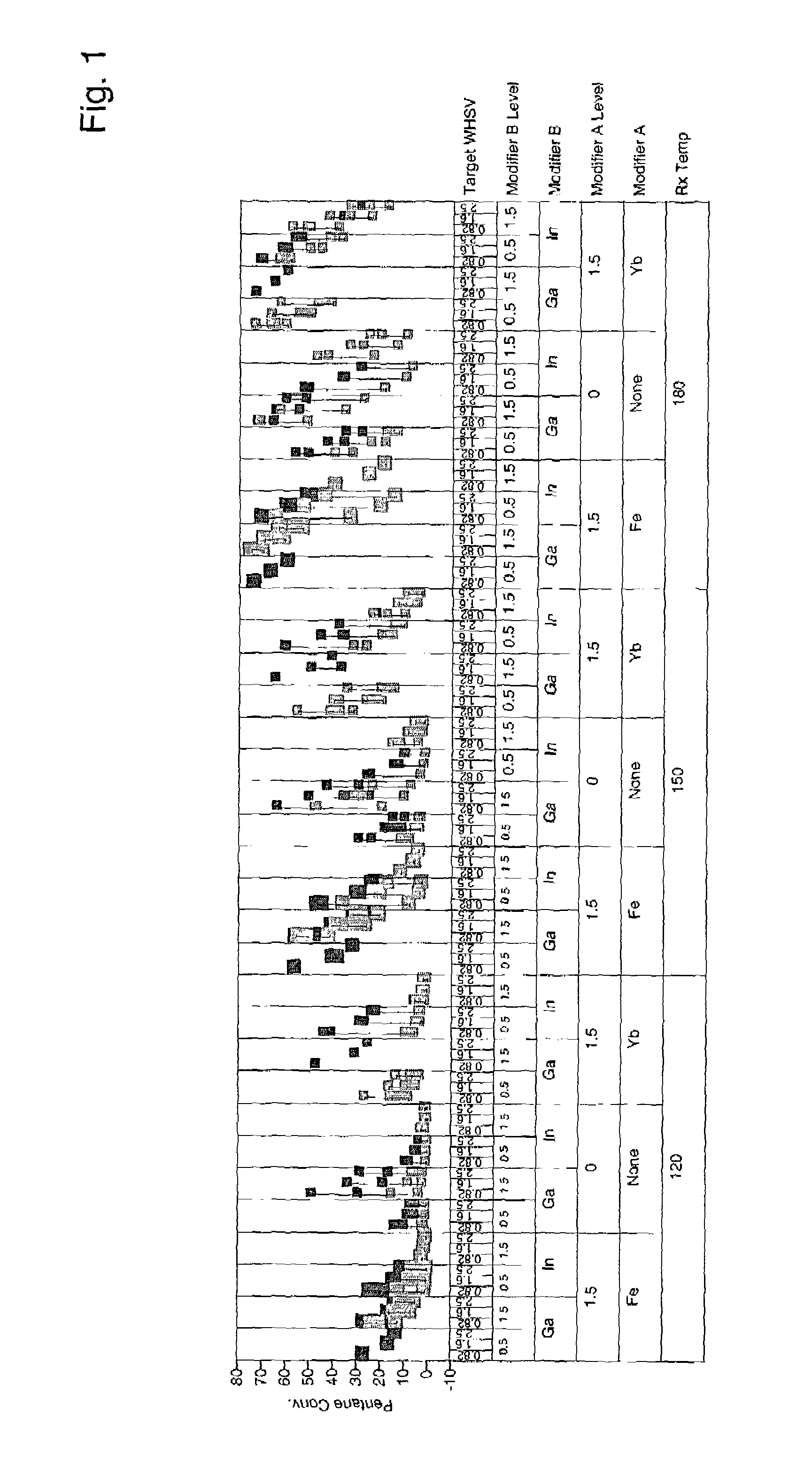

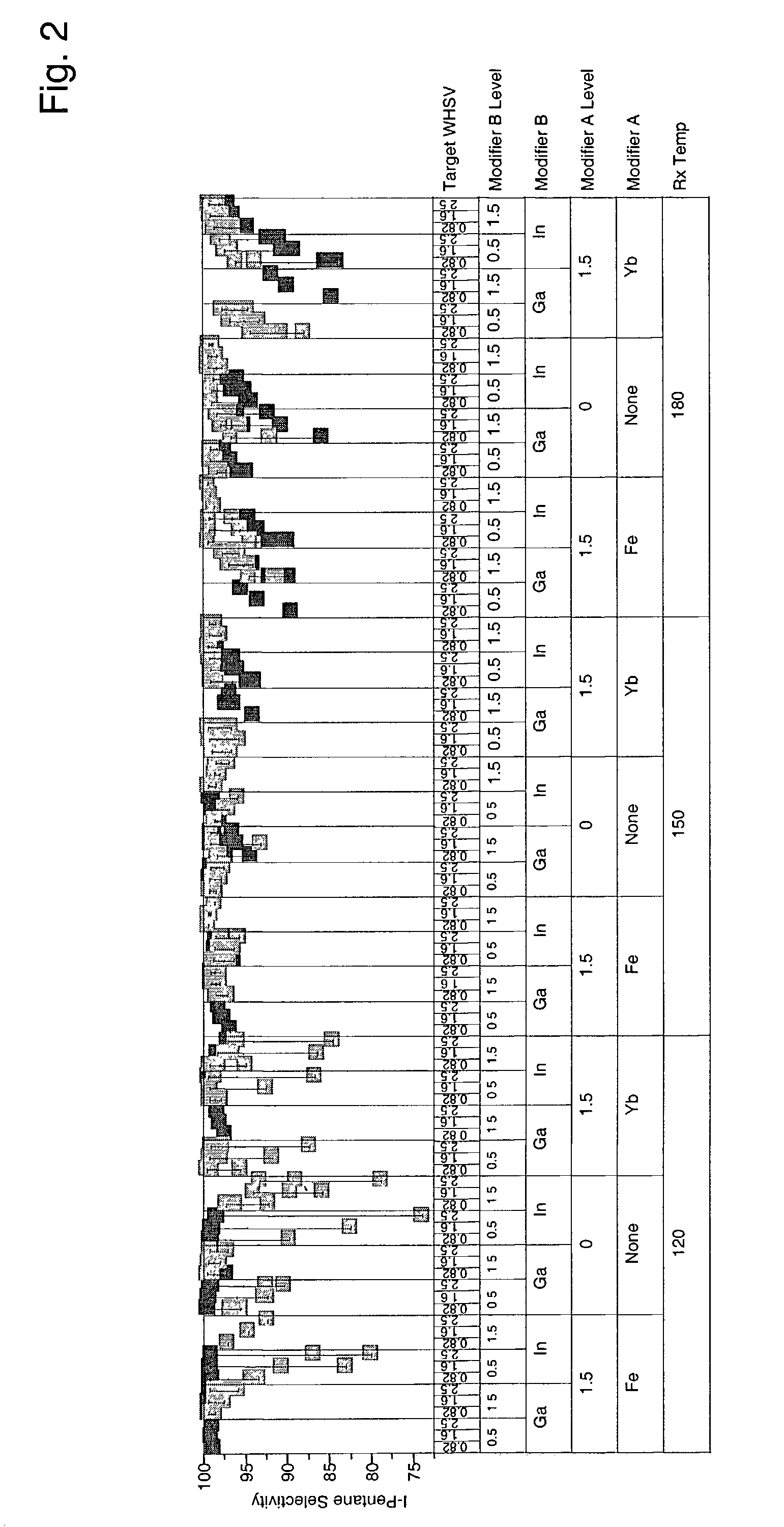

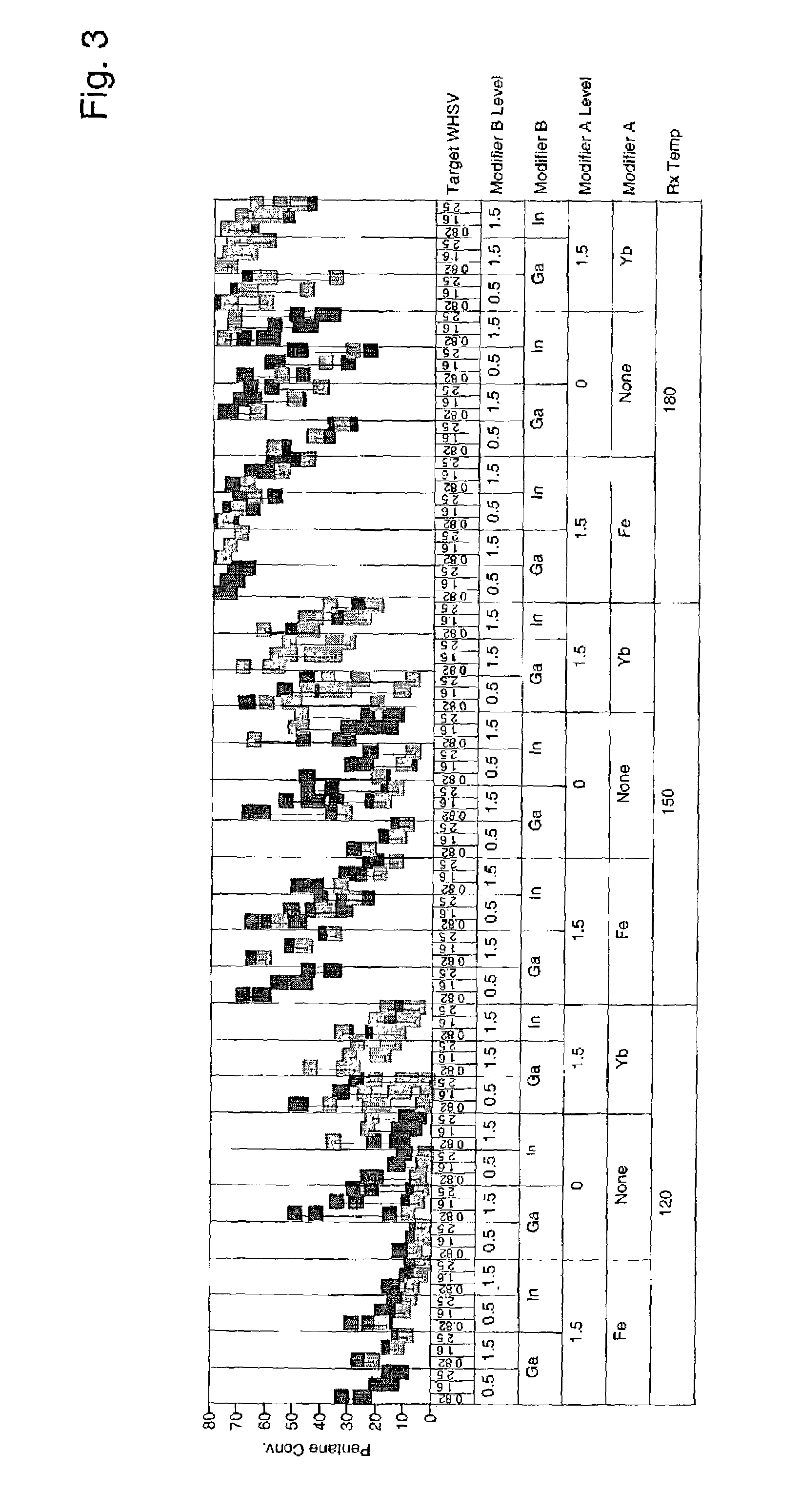

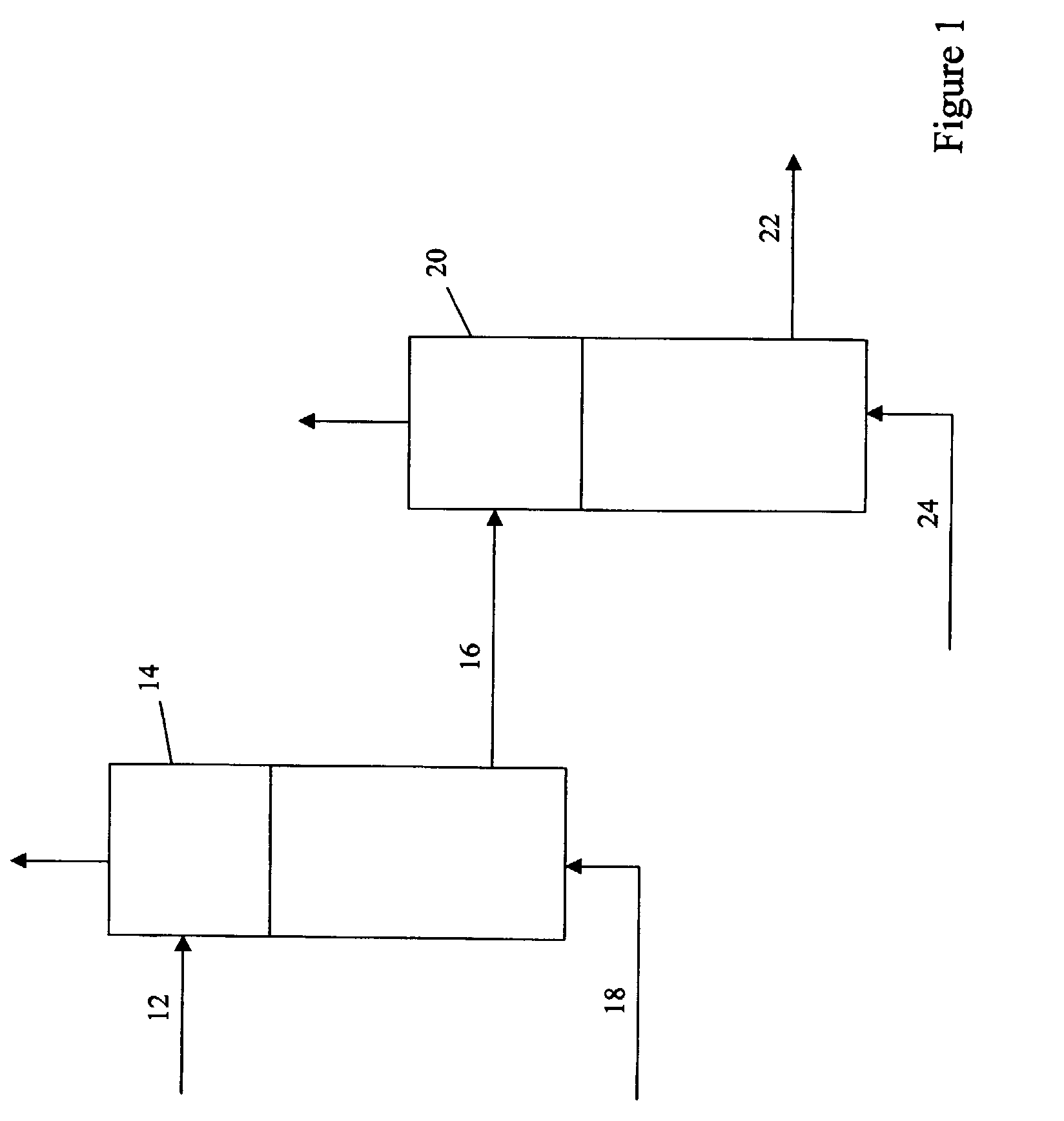

A catalyst and process is disclosed to selectively upgrade a paraffinic feedstock to obtain an isoparaffin-rich product for blending into gasoline. The catalyst comprises a support of a sulfated oxide or hydroxide of a Group IVB (IUPAC 4) metal, a first component comprising at least one Group III A (IUPAC 13) component, and at least one platinum-group metal component which is preferably platinum.

Owner:UOP LLC

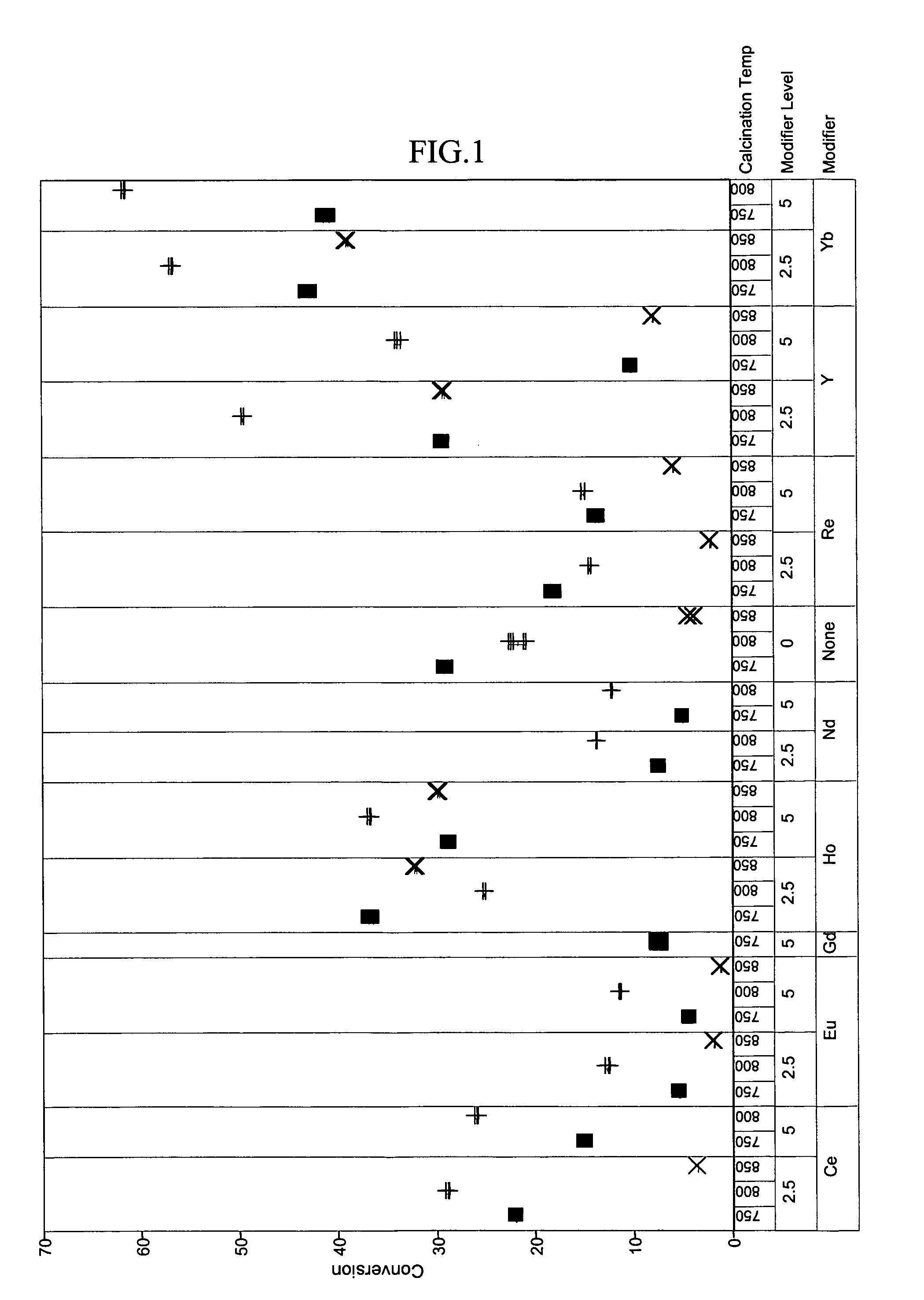

Isomerization catalyst and processes

InactiveUS6977322B2Improve performanceImprove stabilityHydrocarbon by isomerisationCatalytic crackingAlkaneIsomerization

A catalyst and process is disclosed to selectively upgrade a paraffinic feedstock to obtain an isoparaffin-rich product for blending into gasoline. The catalyst comprises a support of a tungstated oxide or hydroxide of a Group IVB (IUPAC 4) metal, a first component of at least one lanthanide element, yttrium or mixtures thereof, which is preferably ytterbium or holmium, and at least one platinum-group metal component which is preferably platinum.

Owner:UOP LLC

Hydrocarbon conversion processes using non-zeolitic molecular sieve catalysts

Hydrocarbon or oxygenate conversion process in which a feedstock is contacted with a non zeolitic molecular sieve which has been treated to remove most, if not all, of the halogen contained in the catalyst. The halogen may be removed by one of several methods. One method includes heating the catalyst in a low moisture environment, followed by contacting the heated catalyst with air and / or steam. Another method includes steam-treating the catalyst at a temperature from 400° C. to 1000° C. The hydrocarbon or oxygenate conversion processes include the conversion of oxygenates to olefins, the conversion of oxygenates and ammonia to alkylamines, the conversion of oxygenates and aromatic compounds to alkylated aromatic compounds, cracking and dewaxing.

Owner:EXXONMOBIL CHEM PAT INC

Catalytic conversion of polycyclic aromatics into xylenes

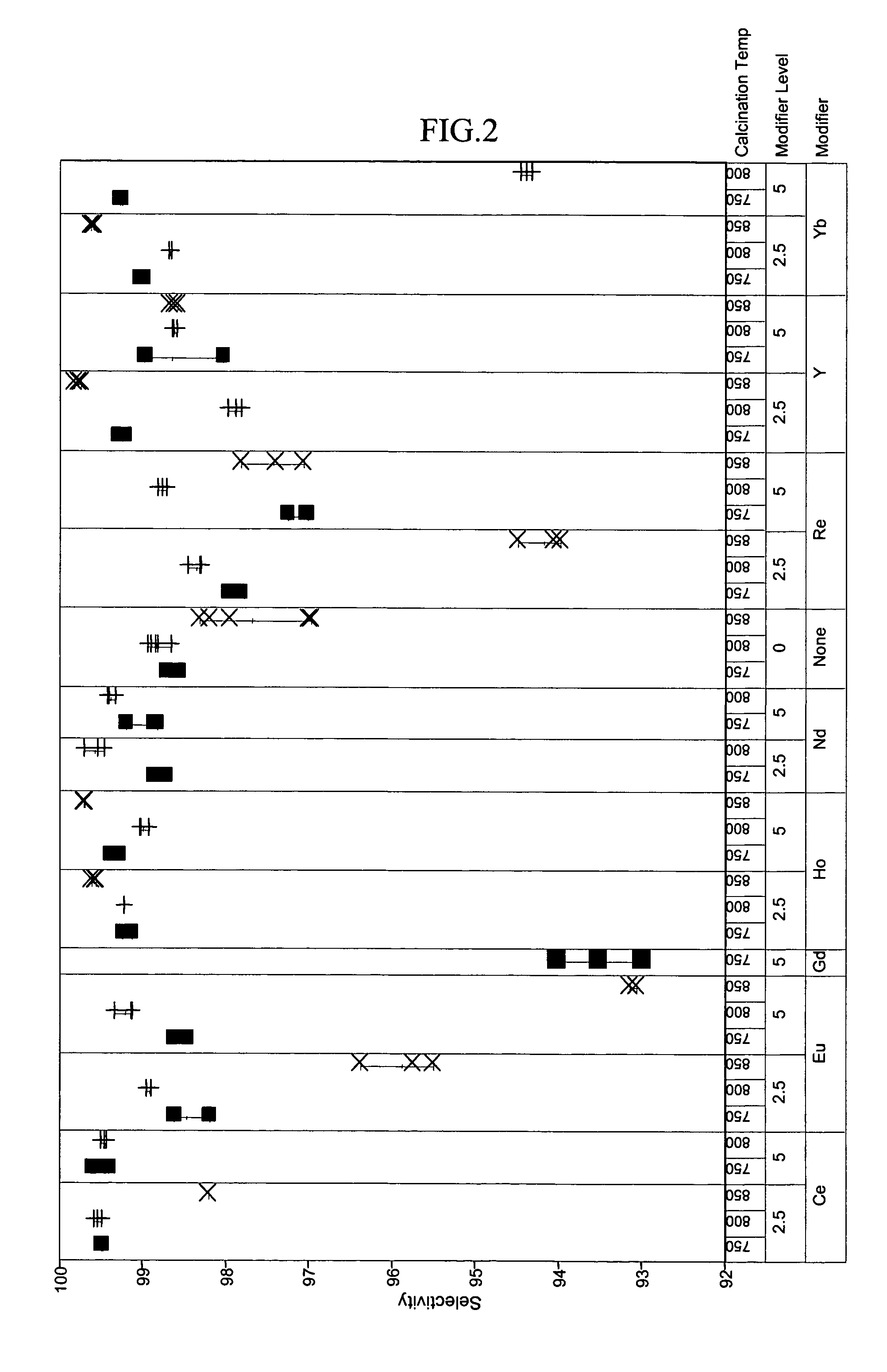

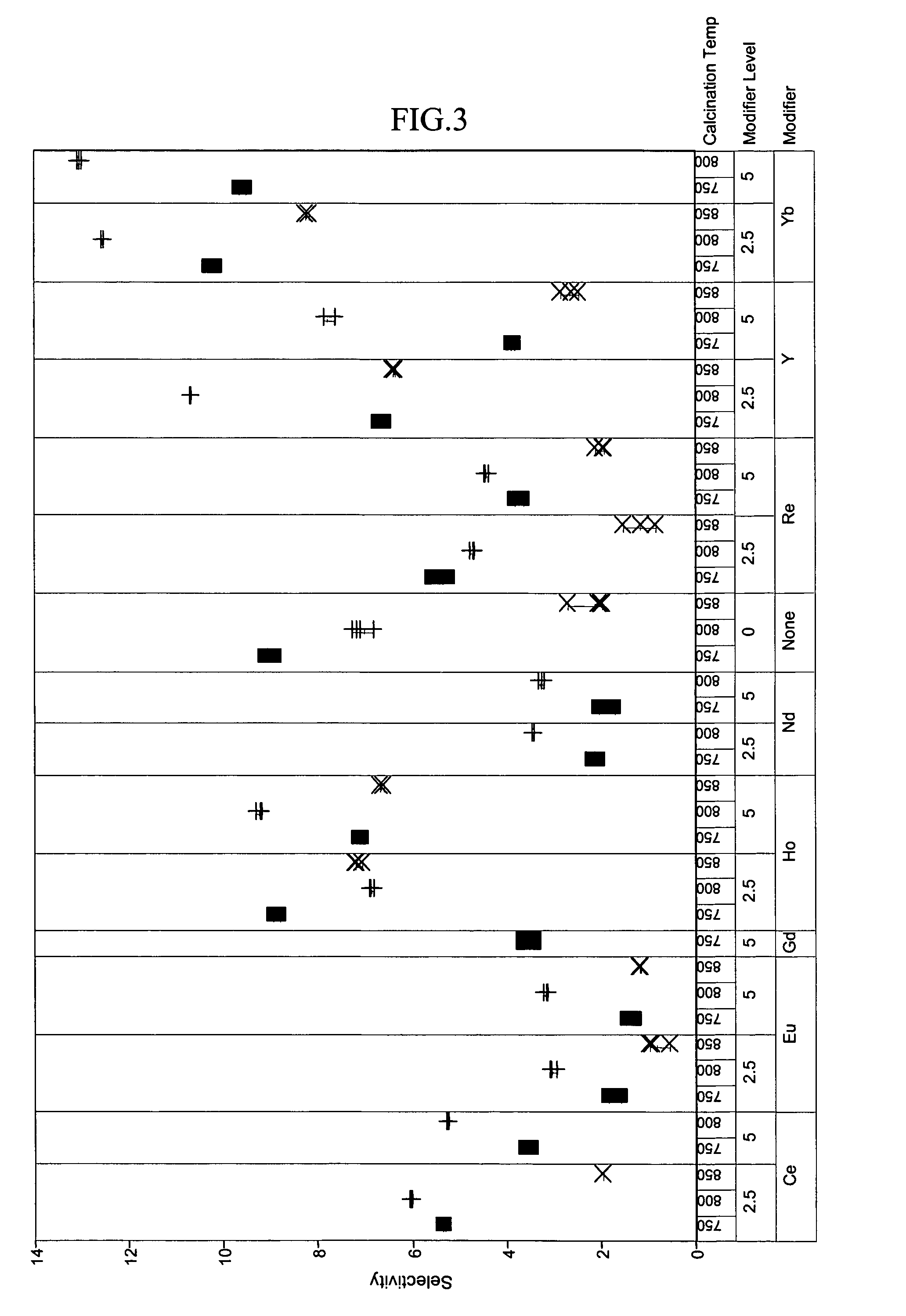

ActiveUS6972348B2High effectiveness for conversionSpeed up the conversion processHydrocarbon by isomerisationMolecular sieve catalystRheniumBoiling point

A catalyst, and a process for using the catalyst, that effectively converts and transalkylates indane and C10 and heavier polycyclic aromatics into C8 aromatics is herein disclosed. The catalyst comprises a solid-acid support such as mordenite plus a metal component such as rhenium. The catalyst provides excellent conversion of such heavy aromatic species as naphthalene, which is also observed by a decrease in the ending-boiling-point of a hydrocarbon stream passed over the catalyst. The same catalyst is also effective for transalkylation of lighter aromatics, thus yielding a valuable xylenes product stream out of the process.

Owner:UOP LLC

Catalytic conversion of polycyclic aromatics into xylenes

ActiveUS20050215838A1High effectiveness for conversionSpeed up the conversion processHydrocarbon by isomerisationMolecular sieve catalystRheniumBoiling point

A catalyst, and a process for using the catalyst, that effectively converts and transalkylates indane and C10 and heavier polycyclic aromatics into C8 aromatics is herein disclosed. The catalyst comprises a solid-acid support such as mordenite plus a metal component such as rhenium. The catalyst provides excellent conversion of such heavy aromatic species as naphthalene, which is also observed by a decrease in the ending-boiling-point of a hydrocarbon stream passed over the catalyst. The same catalyst is also effective for transalkylation of lighter aromatics, thus yielding a valuable xylenes product stream out of the process.

Owner:UOP LLC

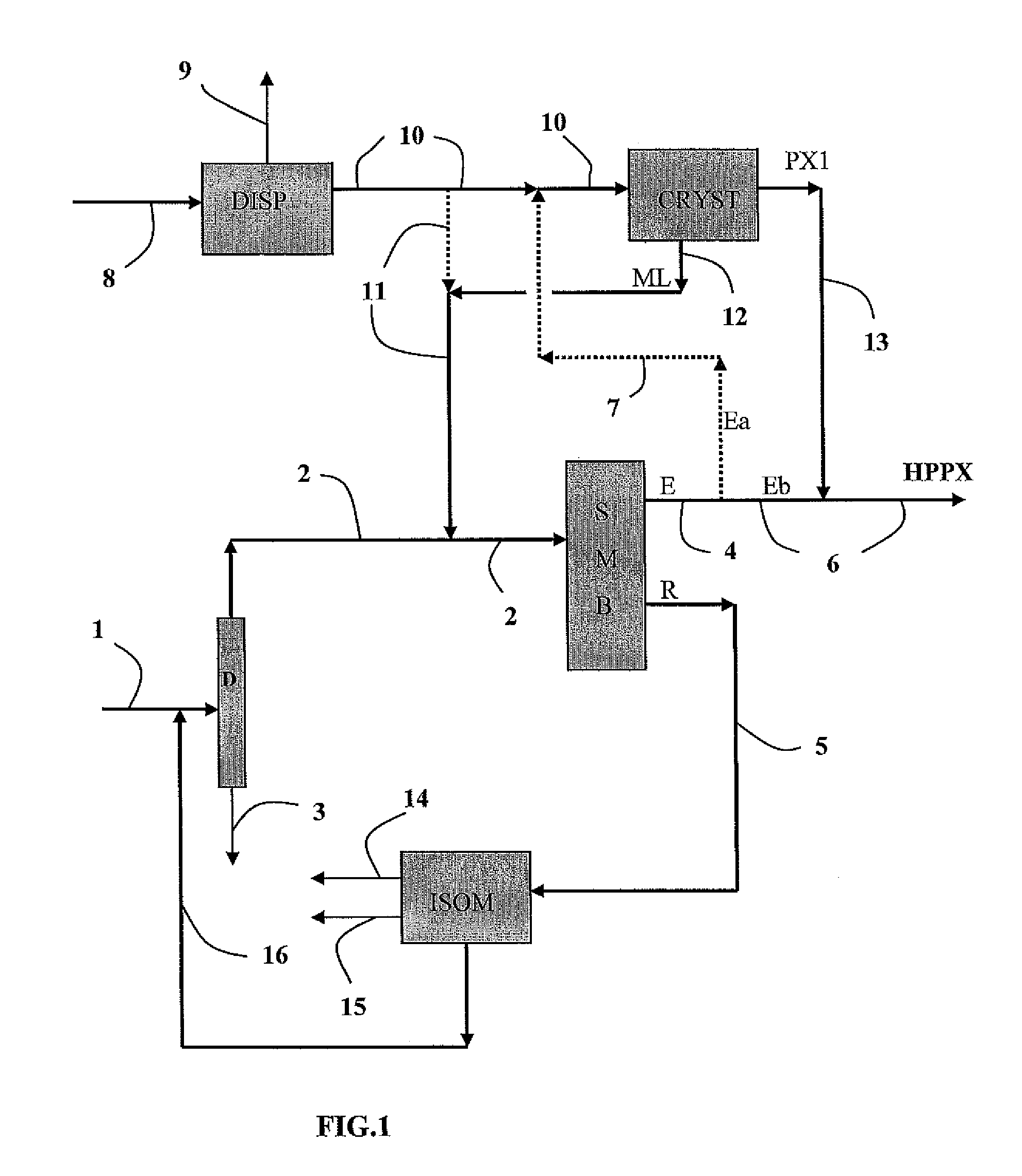

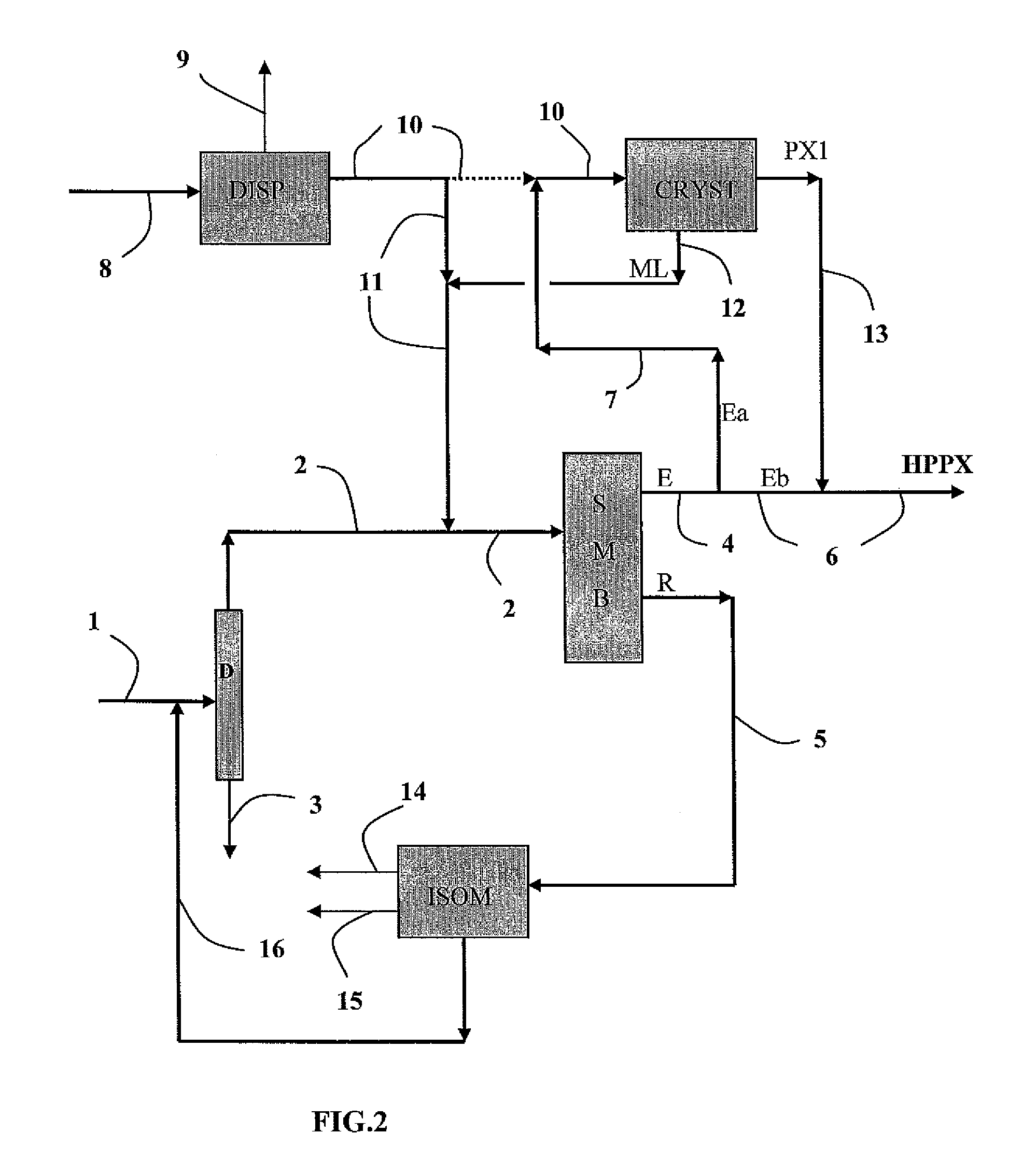

Method for combined production of paraxylene and benzene with improved productivity

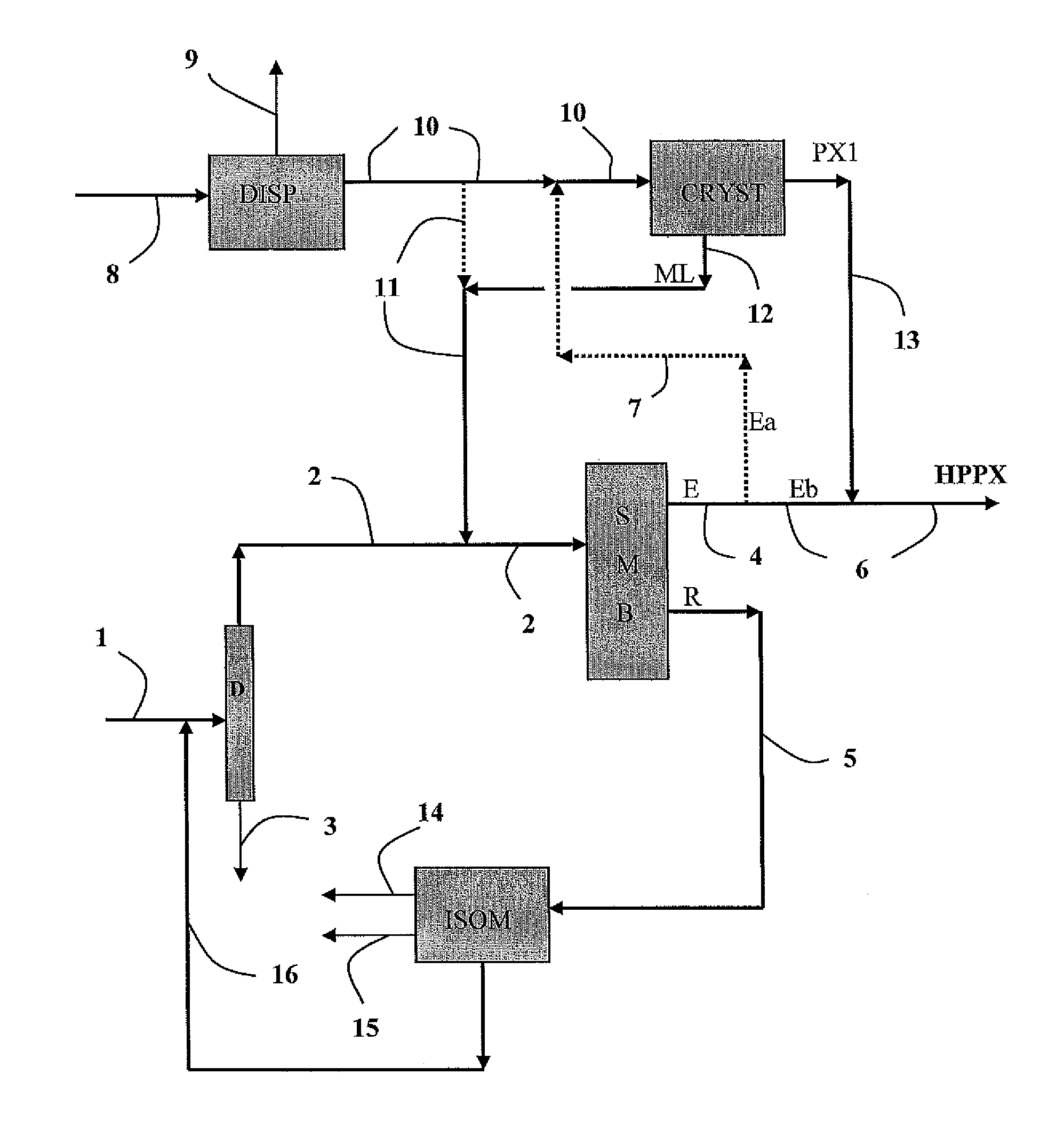

ActiveUS8030533B2Limiting drop in productionIncrease the number ofHydrocarbon by isomerisationHydrocarbonsProduction rateSimulated moving bed

A process for the combined production of para-xylene and benzene comprises:separating a first feed, by adsorption in a simulated moving bed SMB, to produce an extract E rich in para-xylene and at least one raffinate R which is depleted in para-xylene;converting a secondary feed of toluene by selective disproportionation to produce benzene and xylenes;a) at the start of the cycle, producing a supplemental quantity of para-xylene in a crystallization unit supplied with the xylenes from the disproportionation;b) at the end of the cycle, when the adsorbant has aged:dividing the distilled extract E into a first fraction Ea and a complementary second fraction Eb;replacing the feed to the initial crystallization by the stream Ea;and recycling the xylenes from the disproportionation to the SMB.The invention enables para-xylene and benzene production to be maintained despite ageing of the SMB absorbent.

Owner:INST FR DU PETROLE

Method of producing monocyclic aromatic hydrocarbons

InactiveUS20140024871A1High yieldHydrocarbon by isomerisationCatalytic crackingDistillationAromatic hydrocarbon

A method of producing monocyclic aromatic hydrocarbons includes bringing a feedstock oil having a 10 vol % distillation temperature of 140° C. or higher and a 90 vol % distillation temperature of 380° C. or lower, into contact with a catalyst for monocyclic aromatic hydrocarbon production containing a crystalline aluminosilicate, in which a content ratio of monocyclic naphthenobenzenes in the feedstock oil is adjusted to 10 mass % to 90 mass %, by mixing a hydrocarbon oil A having a 10 vol % distillation temperature of 140° C. or higher and a 90 vol % distillation temperature of 380° C. or lower with a hydrocarbon oil B containing more monocyclic naphthenobenzenes than the hydrocarbon oil A.

Owner:JX NIPPON OIL & ENERGY CORP

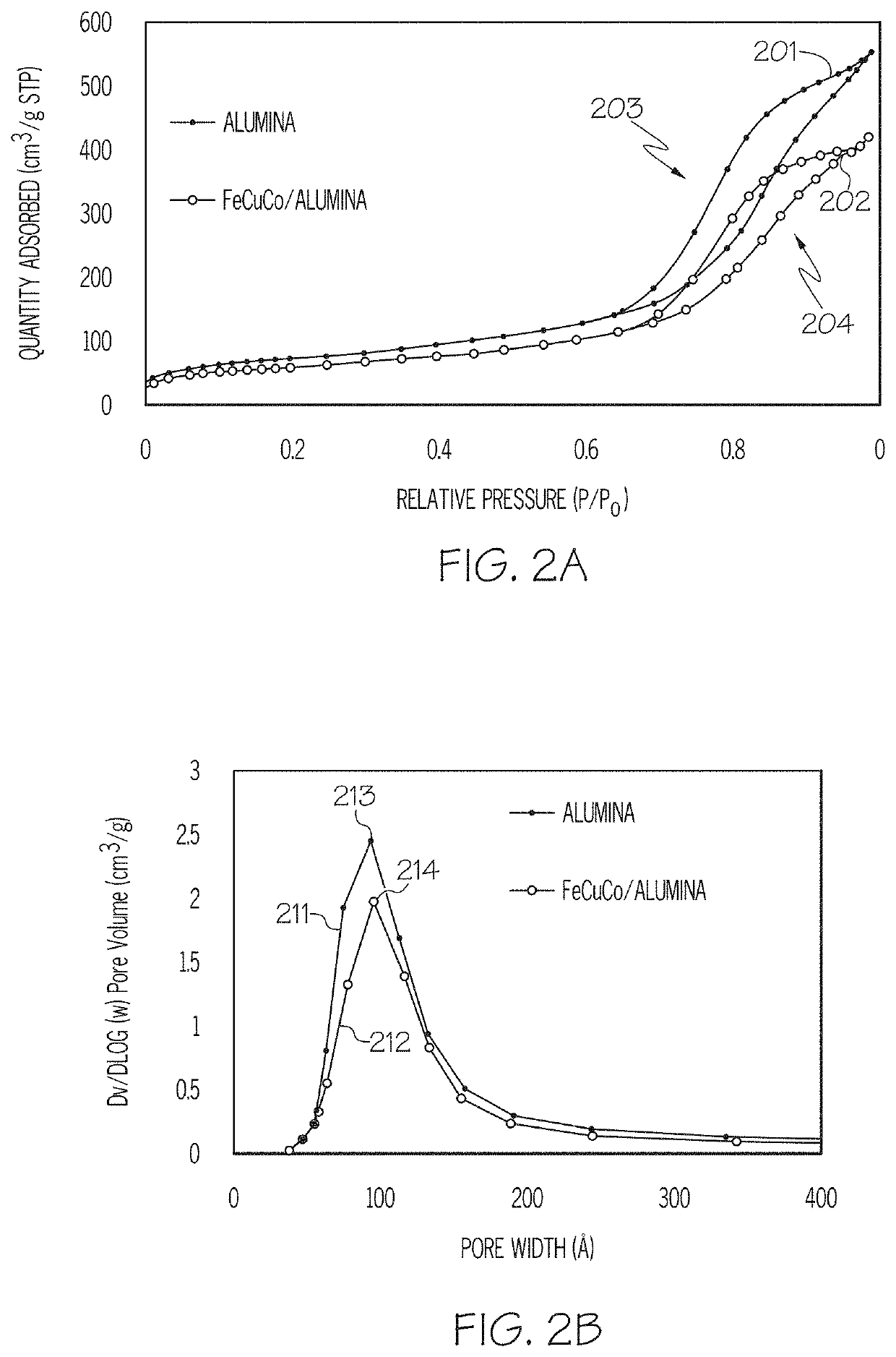

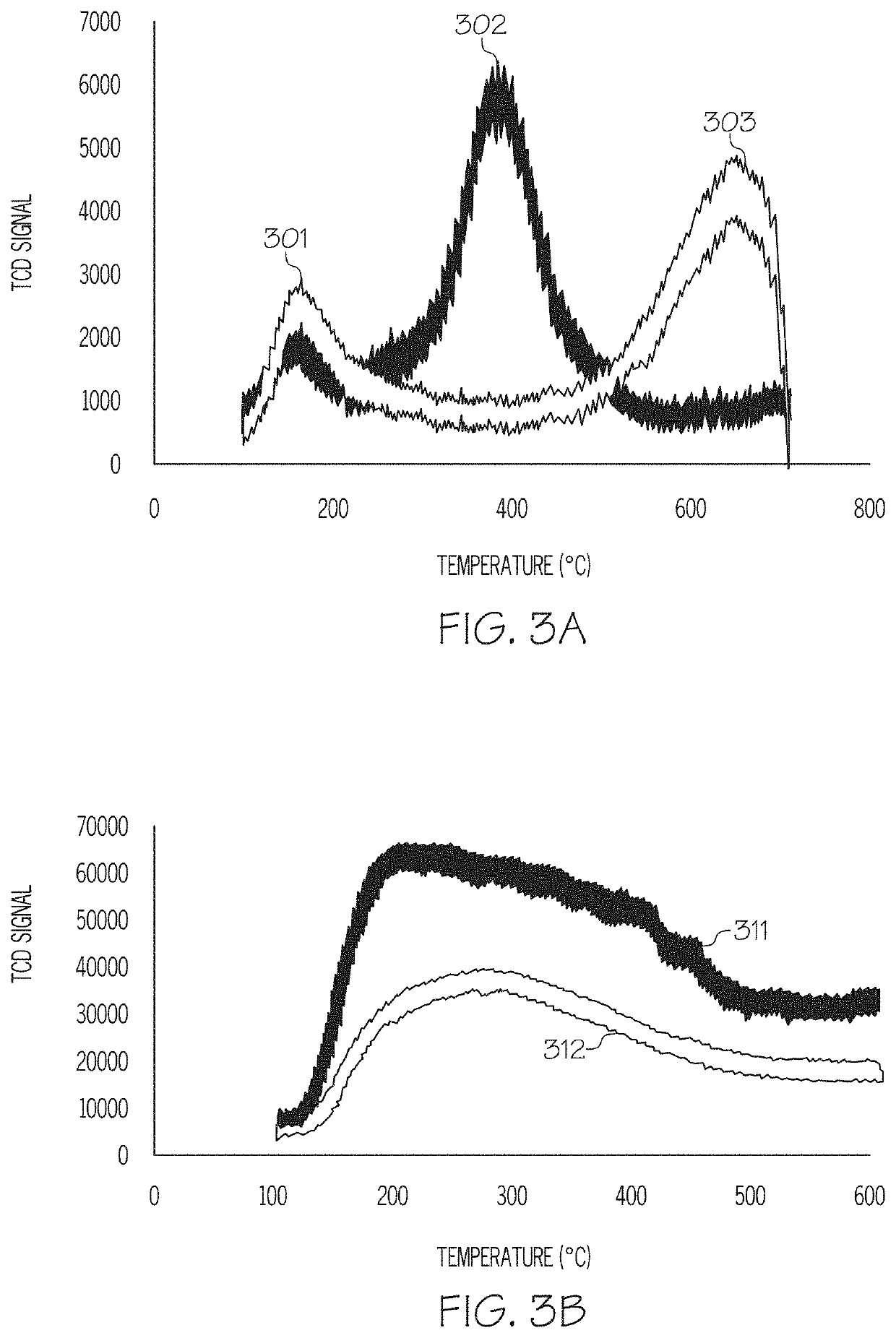

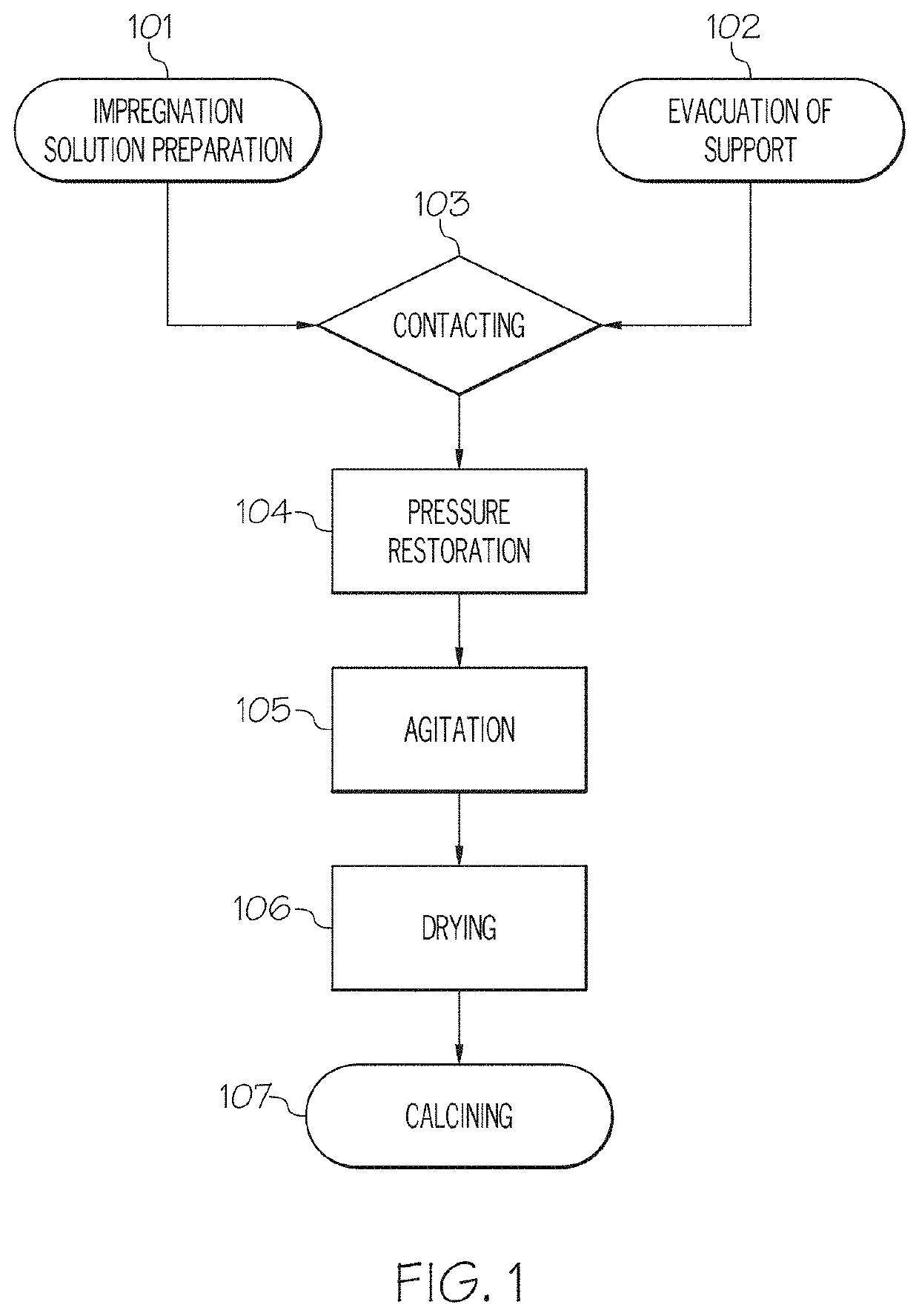

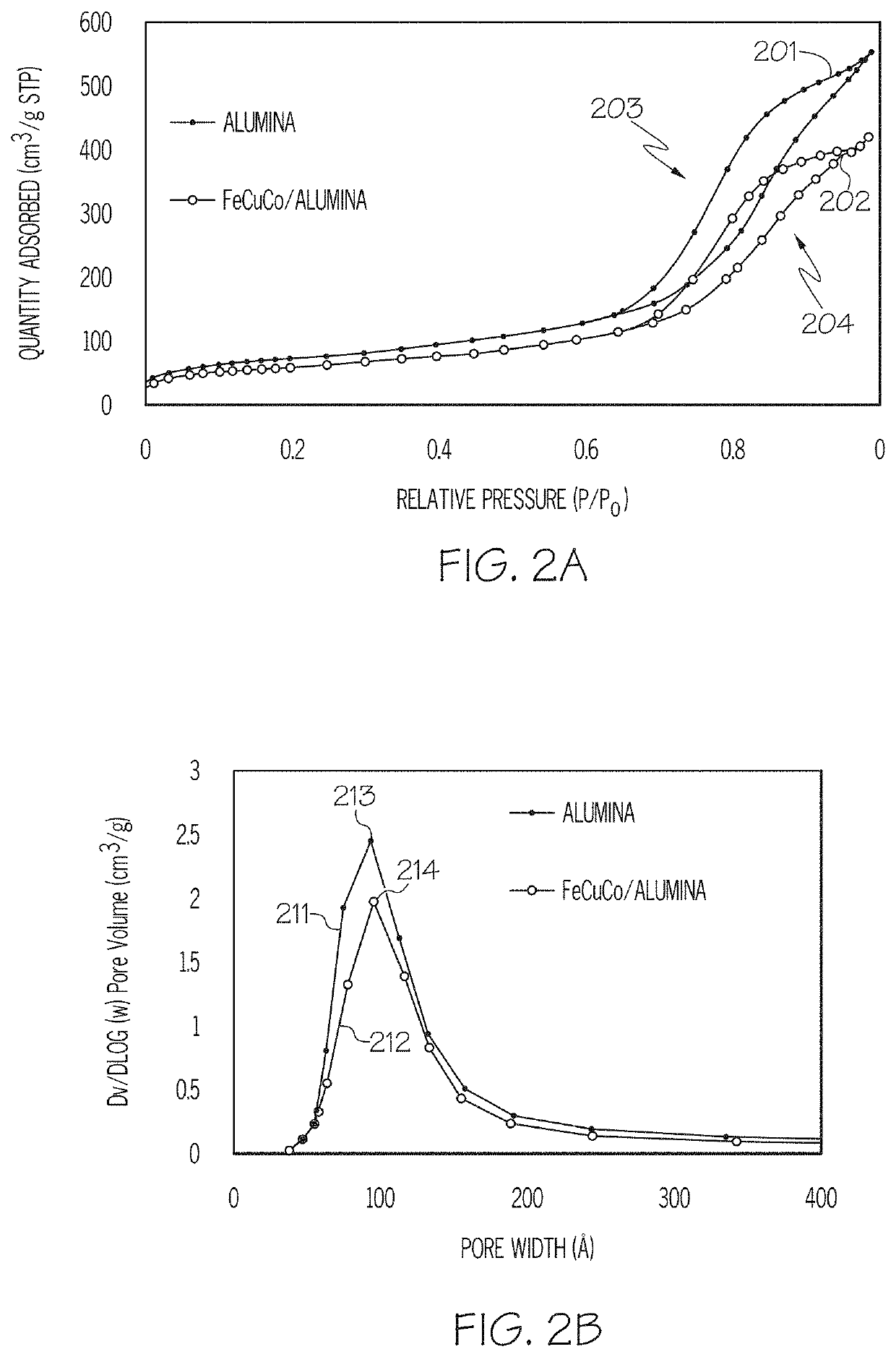

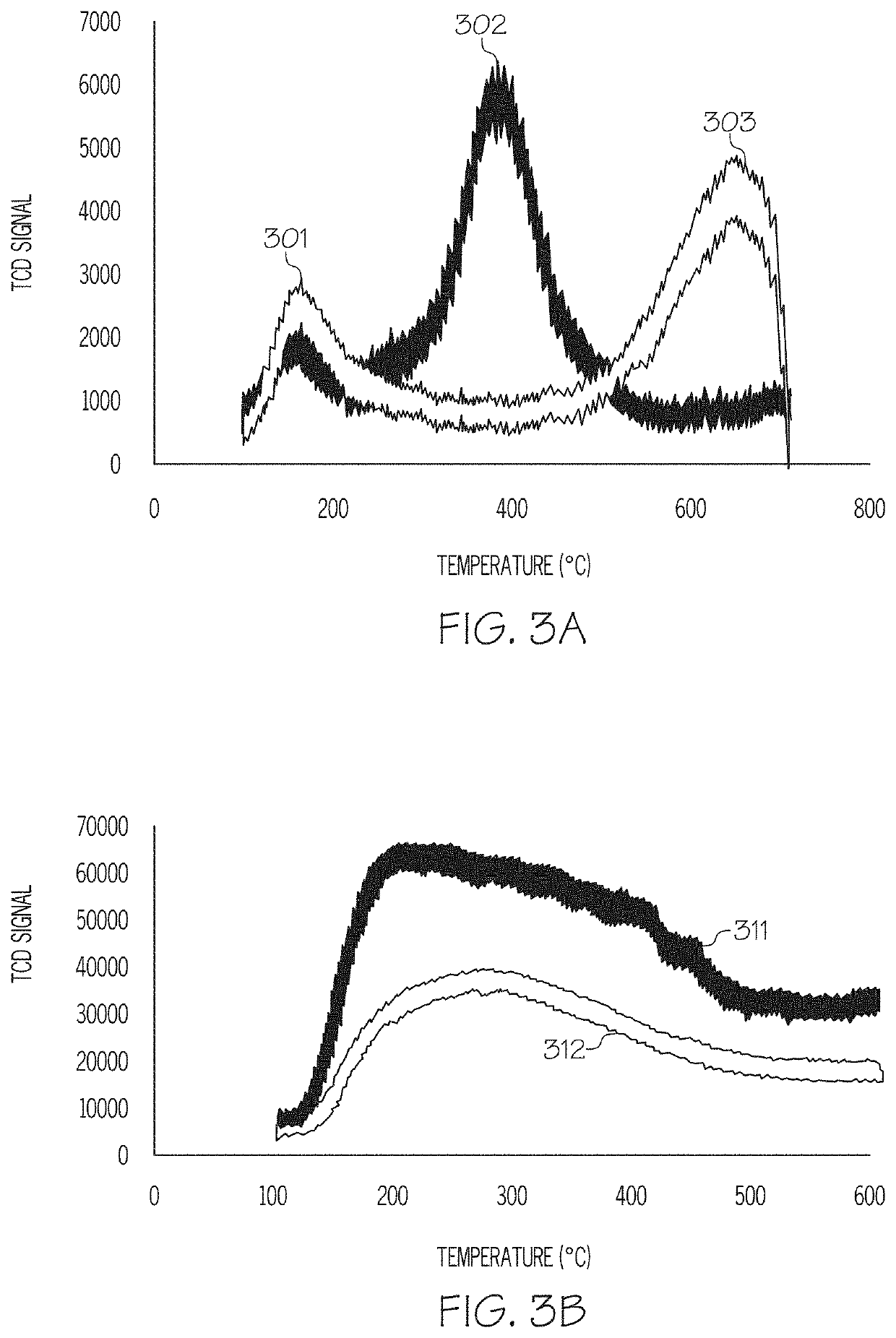

Aromatics hydrogenolysis using novel mesoporous catalyst system

InactiveUS20060014995A1Improve accessibilityHydrocarbon by isomerisationHydrocarbon by polyaryl split-offArylMetal

A process for the selective ring opening of ring-containing hydrocarbons in a feed stream having at least 10% ring-containing hydrocarbons includes contacting the feed stream with a ring opening catalyst containing a metal or a mixture of metals active for the selective ring opening of the ring-containing hydrocarbons on a support material, wherein the support material is a non-crystalline, porous inorganic oxide or mixture of inorganic oxides having at least 97 volume percent interconnected mesopores based on micropores and mesopores, and wherein the ring-containing hydrocarbons have at least one C6 ring and at least one substituent selected from the group consisting of fused 5- or 6-membered rings, alkyl, cycloalkyl and aryl groups.

Owner:ABB LUMMUS GLOBAL INC

Catalyst for producing monocyclic aromatic hydrocarbons and production method of monocyclic aromatic hydrocarbons

InactiveUS20130267749A1High yieldReduction in yieldHydrocarbon by isomerisationMolecular sieve catalystsPolycyclic aromatic hydrocarbonCarbon number

The catalyst for producing monocyclic aromatic hydrocarbons is for producing monocyclic aromatic hydrocarbons having 6 to 8 carbon number from oil feedstock having a 10 volume % distillation temperature of 140° C. or higher and a 90 volume % distillation temperature of 380° C. or lower. The catalyst includes crystalline aluminosilicate, phosphorus, and a binder, and the amount of phosphorus is 0.1 to 10 mass % based on the total mass of the catalyst.

Owner:JX NIPPON OIL & ENERGY CORP

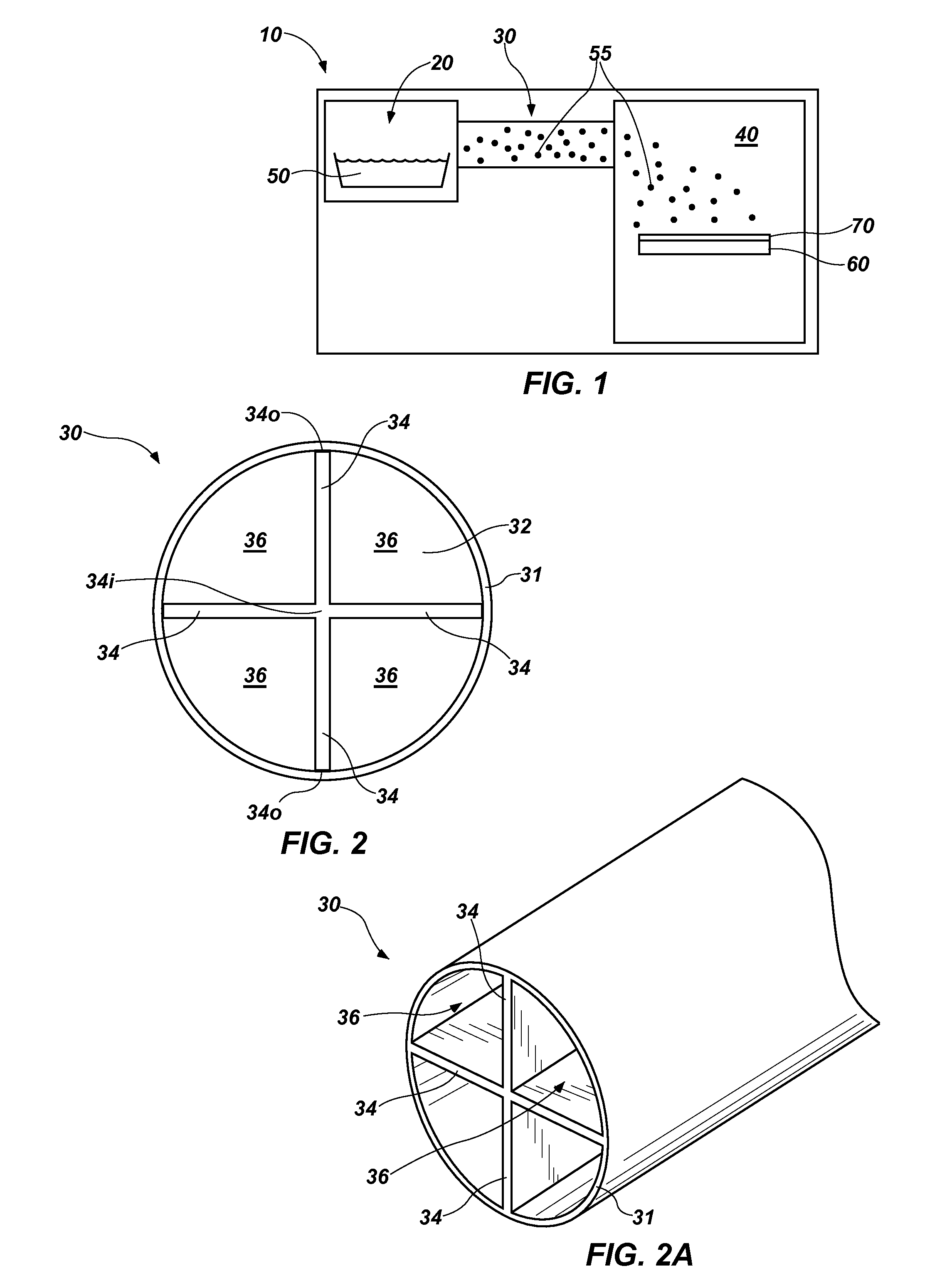

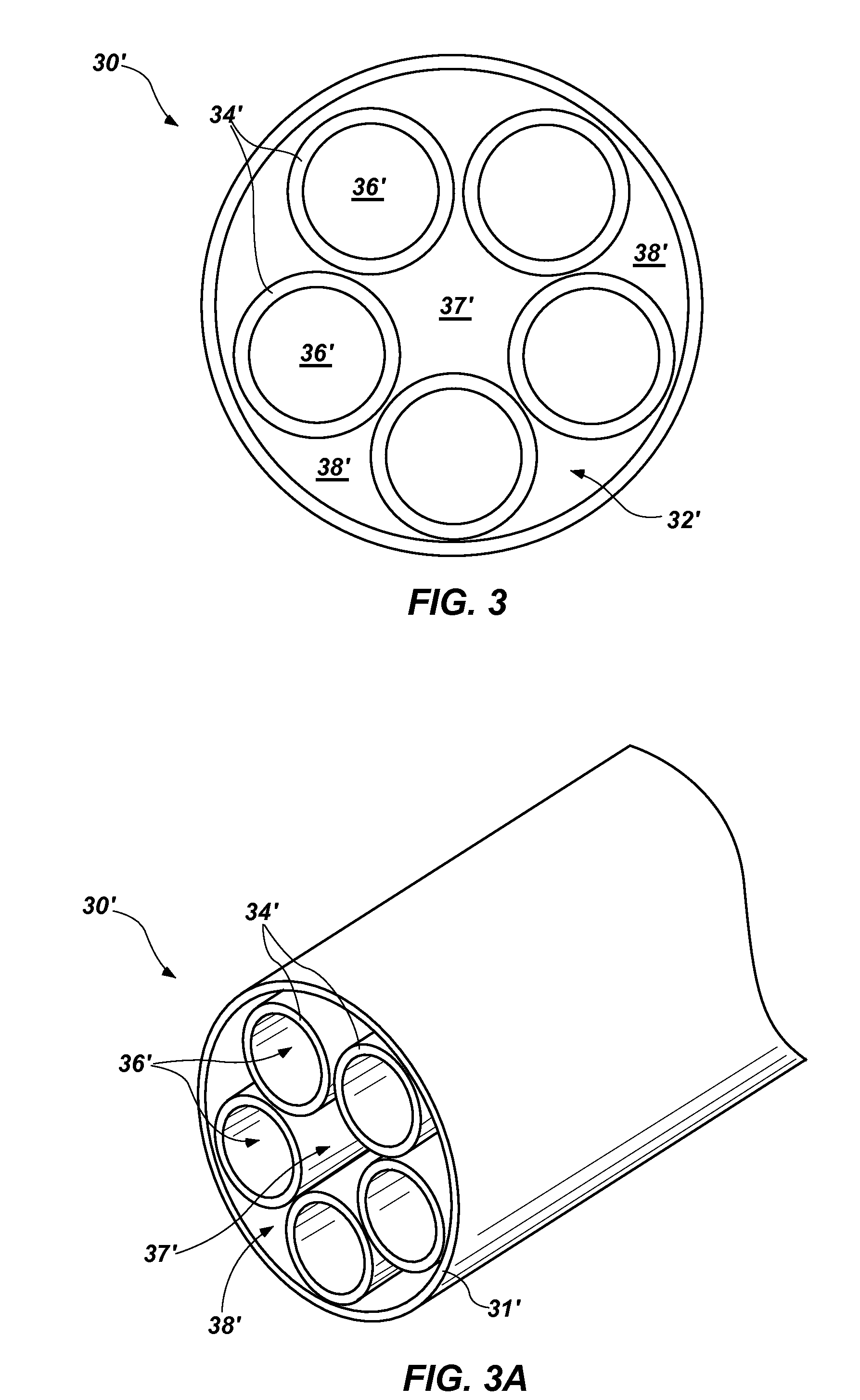

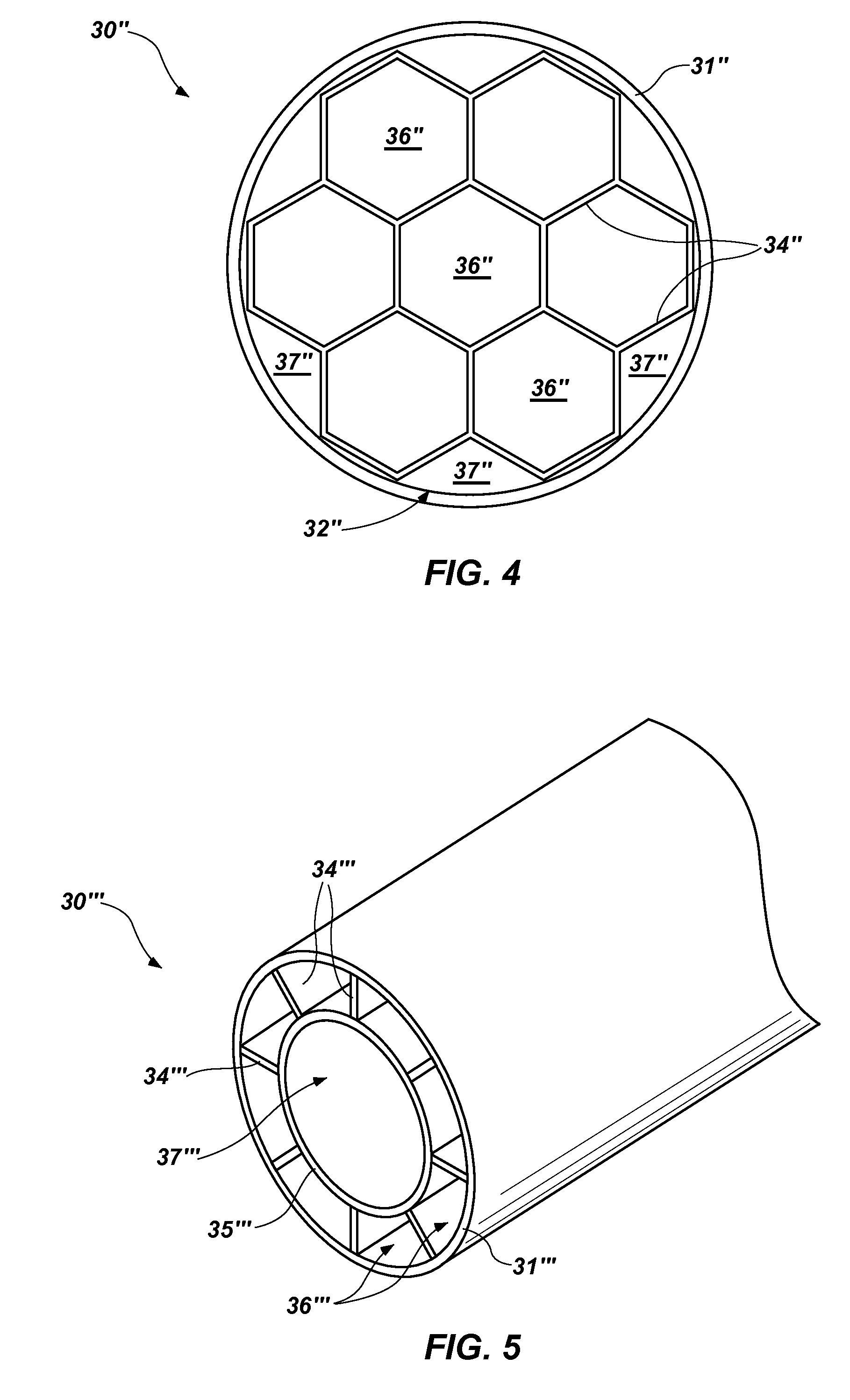

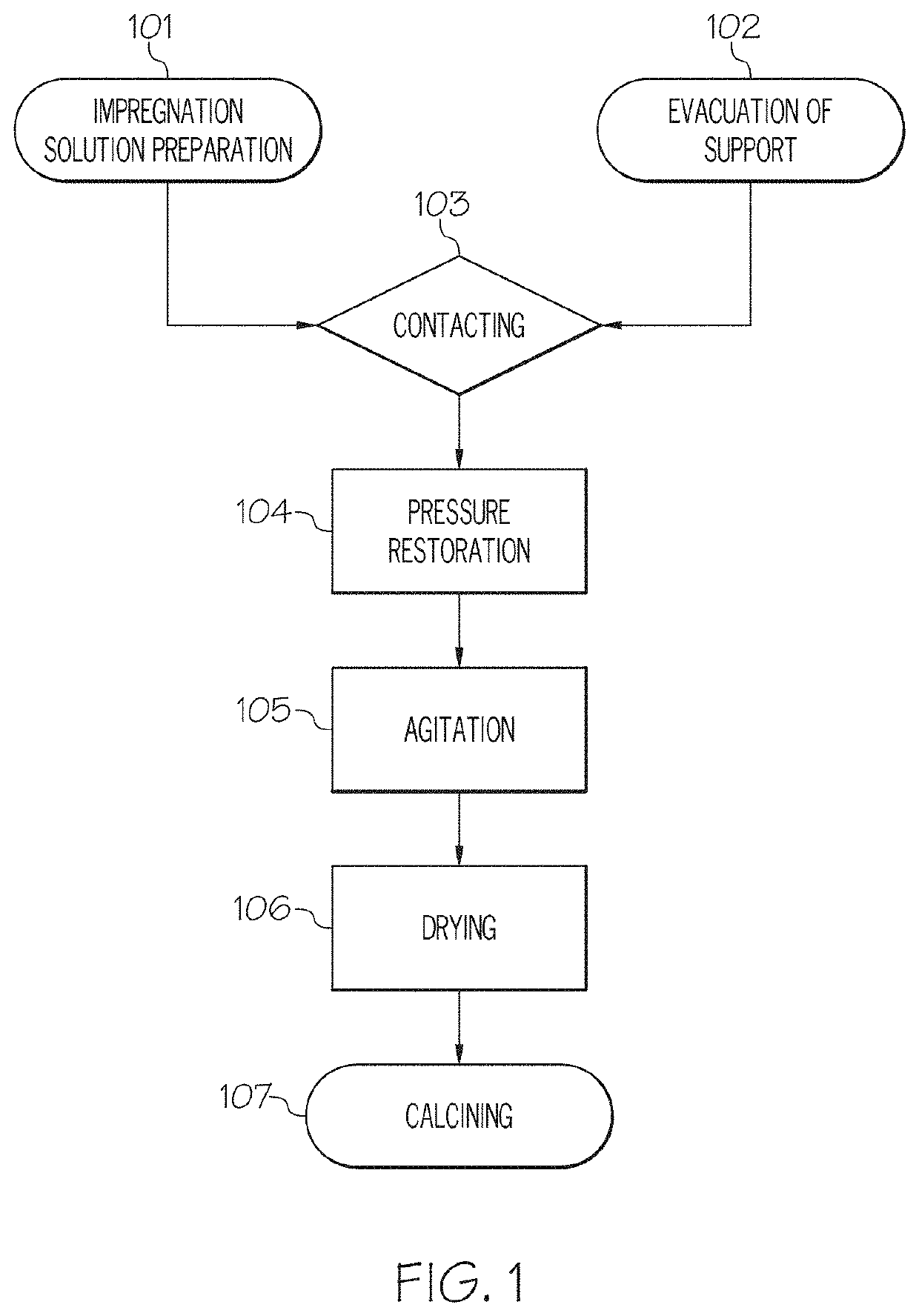

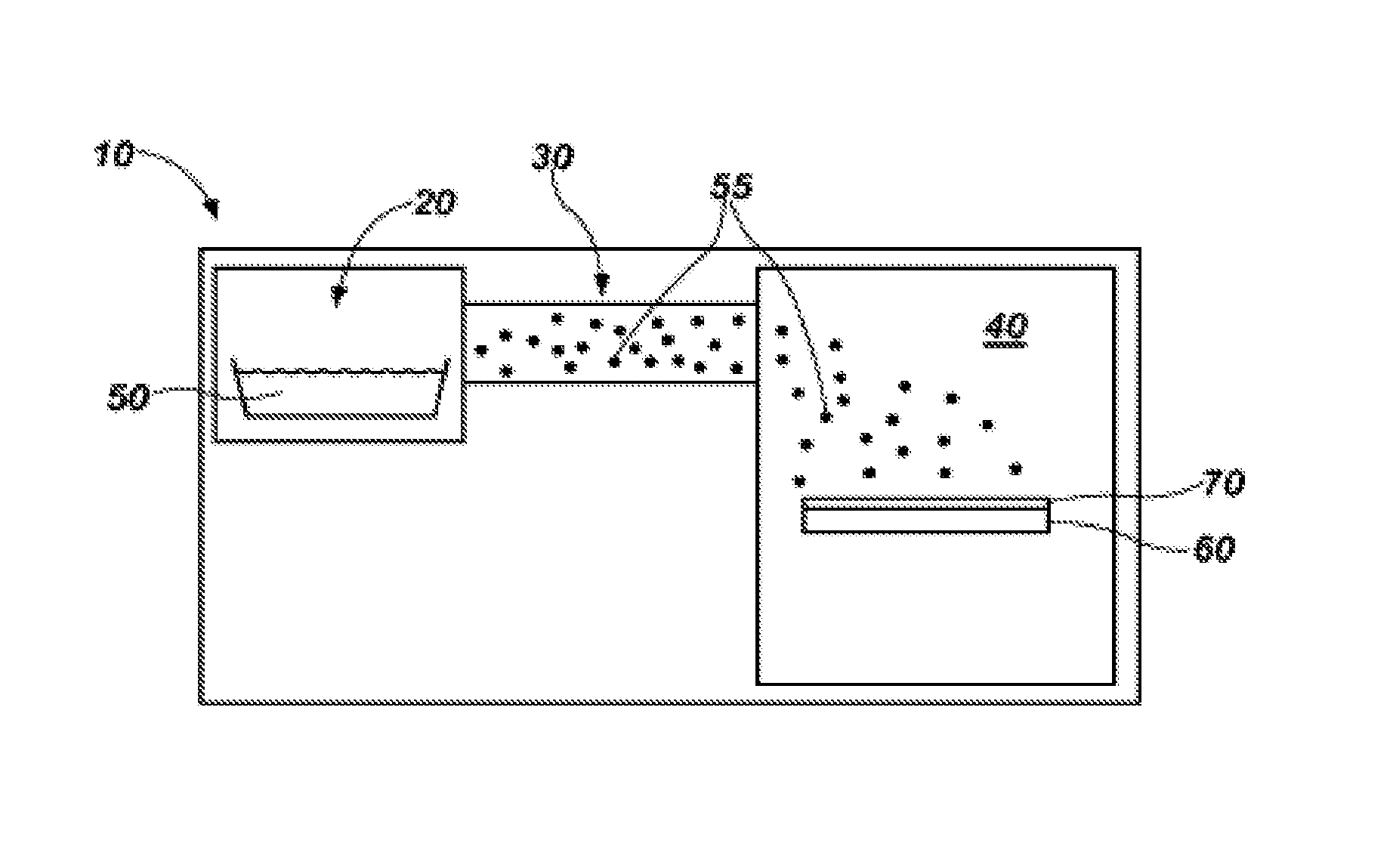

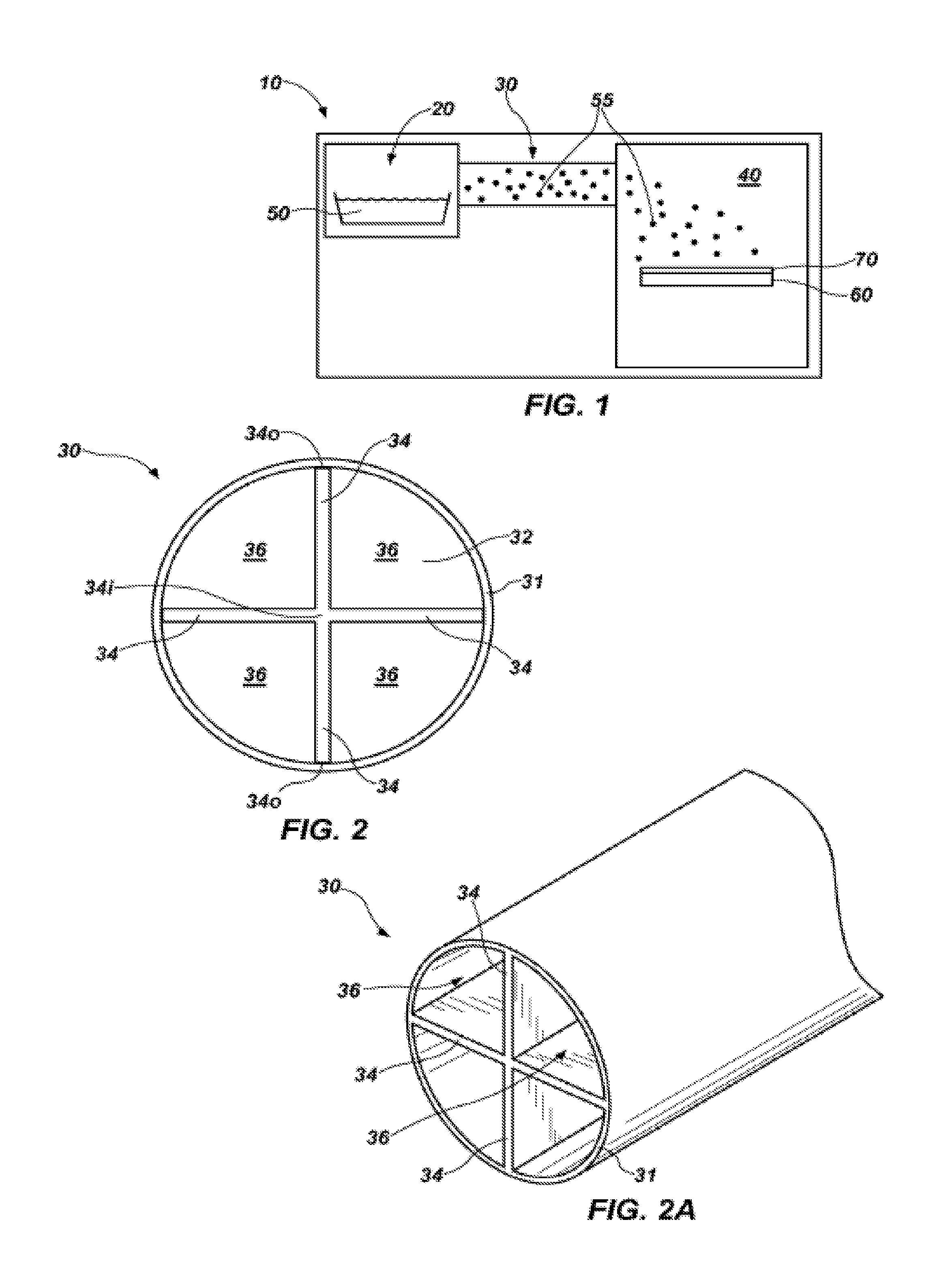

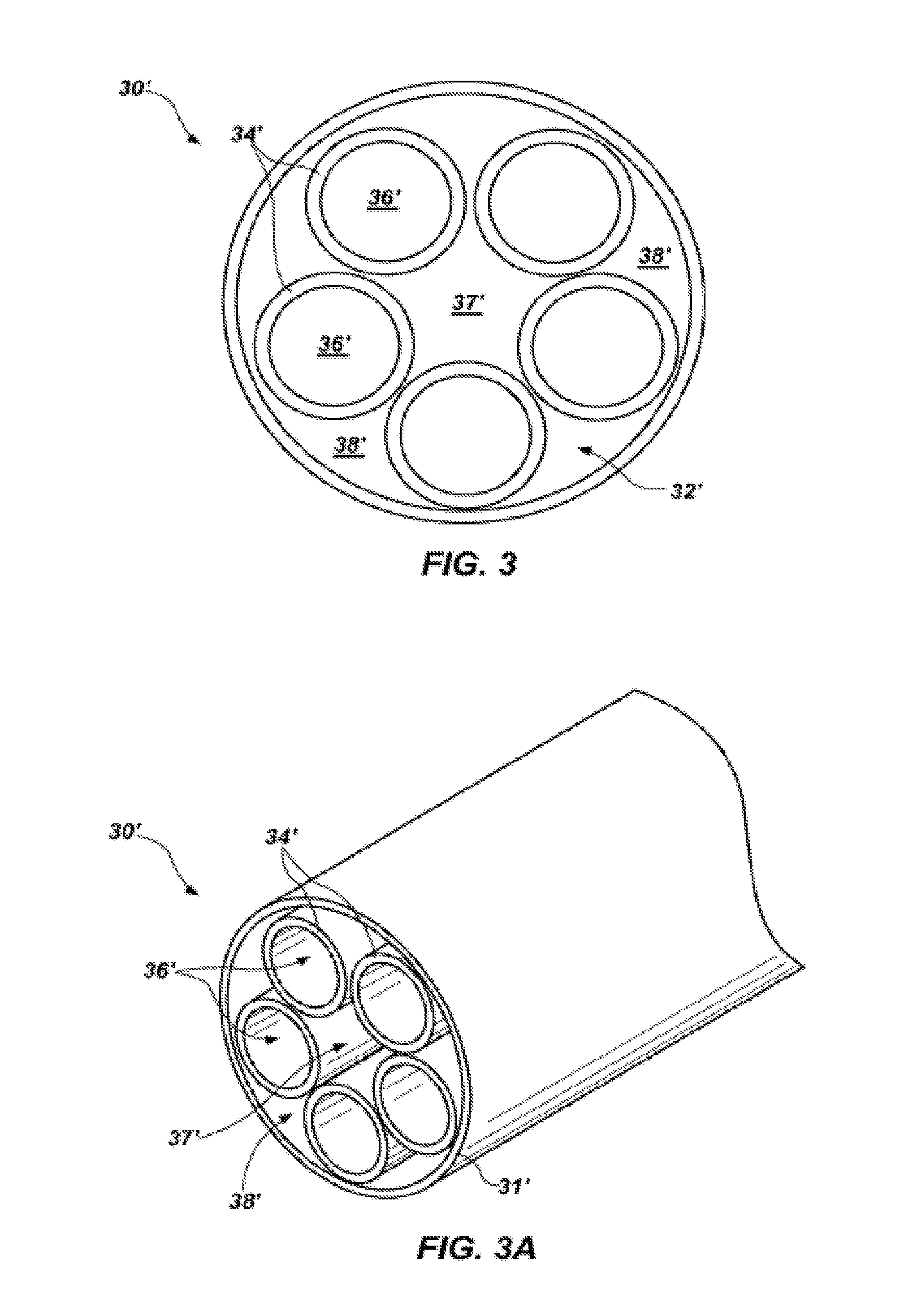

Multi-channel pyrolysis tubes, material deposition equipment including the same and associated methods

InactiveUS20150211115A1Easy to useShorten the timeHydrocarbon by isomerisationLiquid surface applicatorsEngineeringBiomedical engineering

A pyrolysis tube for use with a material deposition system includes a plurality of channels. The channels may be defined by internal elements of the pyrolysis tube, or by internal elements that form an insert for a conventionally configured pyrolysis tube. One or more of the channels may extend straight through the pyrolysis tube, providing a direct line of sight through the pyrolysis tube. Material deposition systems that include such an insert or pyrolysis tube are also disclosed, as are methods for efficiently pyrolyzing precursor materials at temperatures that are reduced relative to conventional pyrolysis temperatures and / or at rates that are increased relative to conventional pyrolysis rates.

Owner:HZO INC

Method for preparing loaded solid super acidic catalyst directly by microwave method

ActiveCN102614926AHigh catalytic hydrocracking activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationTrimethylsilyl trifluoromethanesulfonatePtru catalyst

The invention relates to a method for preparing a loaded solid super acidic catalyst directly by a microwave method, and belongs to a method for preparing a super acidic catalyst. The method comprises the following steps of: (1) mixing and stirring NaHCO3 and a carbon nano tube in a weight ratio of 1:500 fully, and roasting in a microwave reactor to obtain a Na-loaded catalyst carrier; (2) heating the Na-loaded catalyst carrier by microwave radiation, adding a mixed solution of antimony pentachloride (SbCl5) and trimethylsilyl trifluoromethanesulfonate (F3CSO3Si(CH3)3) dropwise, stirring and immersing to obtain a suspension mixed solution; (3) filtering the suspension mixed solution to obtain a solid precursor and a mixed solution; (4) putting the solid precursor into the microwave reactor, heating by the microwave radiation, and roasting to obtain a solid super acidic catalyst prototype; and (5) performing operation for 1 to 5 times by taking the solid super acidic catalyst prototype as a raw material according to the steps (2), (3) and (4) to obtain the solid-loaded super acidic catalyst. The method has the advantages that: the loaded solid super acidic catalyst prepared by the microwave method is high in catalytic hydrocracking activity and selectivity.

Owner:CHINA UNIV OF MINING & TECH

Method for producing monocyclic aromatic hydrocarbons

ActiveUS20140012055A1High yieldHydrocarbon by isomerisationCatalytic crackingDistillationAromatic hydrocarbon

A method of producing monocyclic aromatic hydrocarbons includes bringing a light feedstock oil having a 10 vol % distillation temperature of 140° C. to 205° C. and a 90 vol % distillation temperature of 300° C. or lower, which has been prepared from a feedstock oil having a 10 vol % distillation temperature of 140° C. or higher and a 90 vol % distillation temperature of 380° C. or lower, into contact with a catalyst for monocyclic aromatic hydrocarbon production containing a crystalline aluminosilicate, in which a content ratio of monocyclic naphthenobenzenes in the light feedstock oil is adjusted by distillation of the feedstock oil such that the content ratio of monocyclic naphthenobenzenes in the light feedstock oil is higher than a content ratio of monocyclic naphthenobenzenes in the feedstock oil.

Owner:JX NIPPON OIL & ENERGY CORP

Process and Catalyst for the Transalkylation of Aromatics

InactiveUS20100298617A1Hydrocarbon by isomerisationHydrocarbon by polyaryl split-offLiquid phasePhosphorus

Disclosed herein is a process and catalyst for producing an ethylbenzene feed from a polyethylbenzene feed, comprising the step of contacting a benzene feed with a polyethylbenzene feed under at least partial liquid phase conditions in the presence of a zeolite beta catalyst having a phosphorus content in the range of 0.01 wt. % to 0.5 wt. % of said catalyst, to provide a product which comprises ethylbenzene.

Owner:EXXONMOBIL CHEM PAT INC

Methods for forming ethylbenzene from polystyrene

ActiveUS20200031738A1Good choiceEfficient CatalysisCatalystsHydrocarbon preparation catalystsPtru catalystPolystyrene

According to one or more embodiments presently disclosed, a method of catalytically converting polystyrene may include contacting polystyrene with a catalyst to form a product comprising ethylbenzene. The catalyst may include oxidized iron, oxidized cobalt, and oxidized copper. The catalyst may further include a mesoporous support material with pores having an average pore diameter of from 2 nm to 50 nm.

Owner:KING ABDULLAH UNIV OF SCI & TECH +1

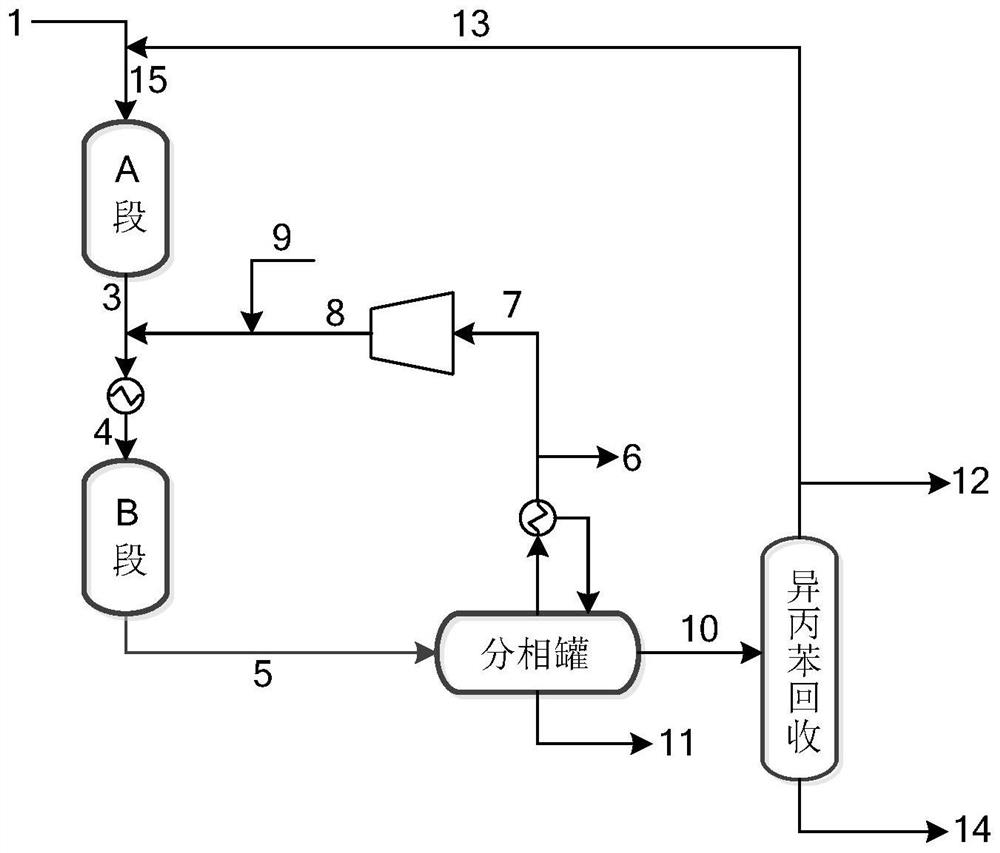

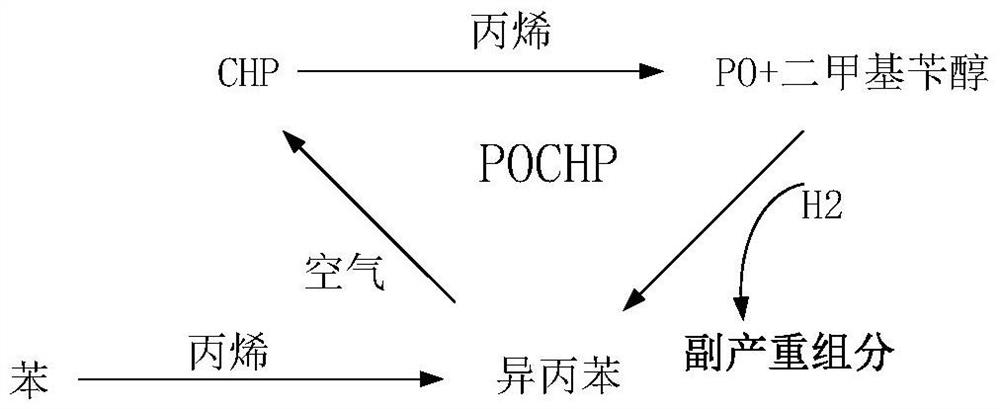

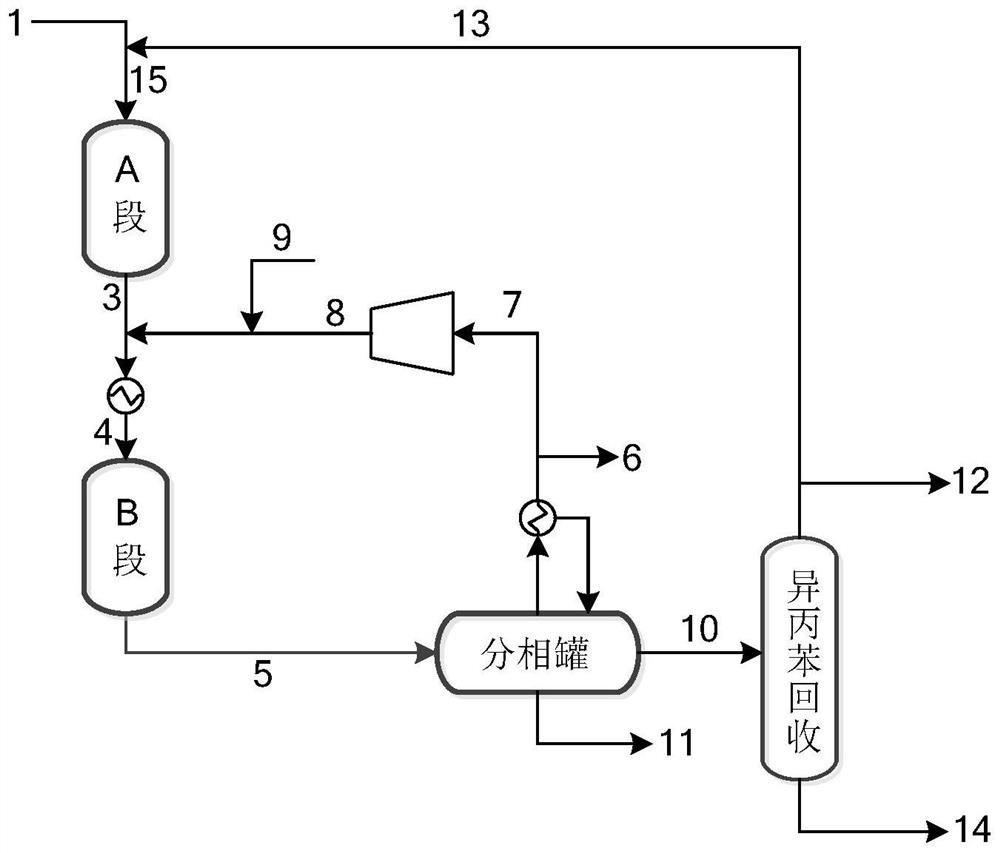

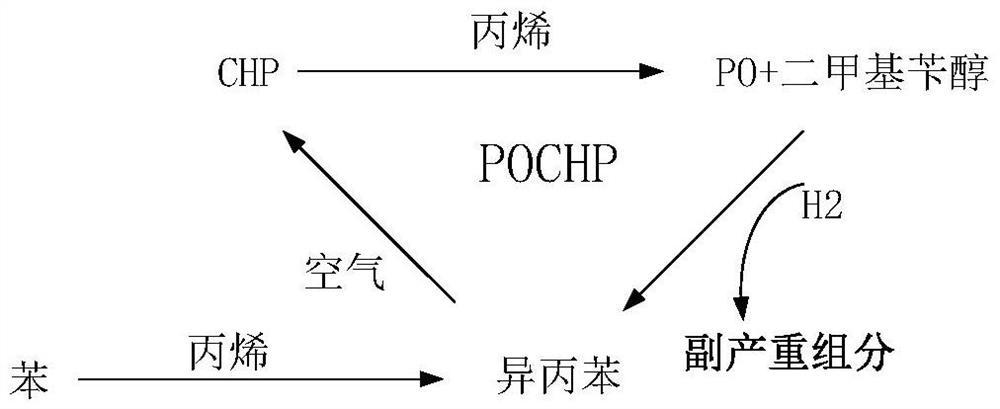

Method for reducing unit consumption of cumene in epoxypropane production process using cumene co-oxidation method

ActiveCN112250534AReduce the unit consumption of cumeneImprove economyHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsBiochemical engineeringProcess engineering

The invention discloses a method for reducing unit consumption of a cumene in epoxypropane production process using a cumene co-oxidation method. In a process for producing epoxypropane by a cumene co-oxidation method, heavy components such as diisopropylbenzene and the like are byproduced when cumene is prepared by hydrogenolysis of dimethyl benzyl alcohol. According to the invention, a heavy component is converted into cumene through two steps of thermal cracking and catalytic hydrogenation to be recycled, so that the economical efficiency and competitiveness of a process for producing epoxypropane through a cumene co-oxidation method are remarkably improved.

Owner:WANHUA CHEM GRP CO LTD

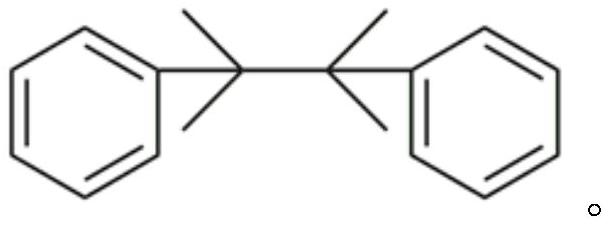

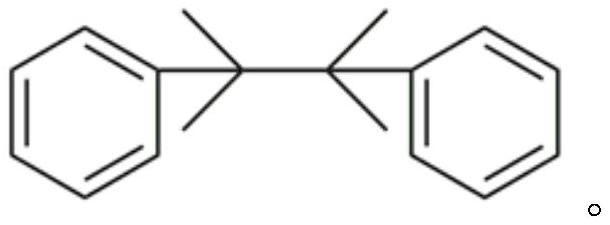

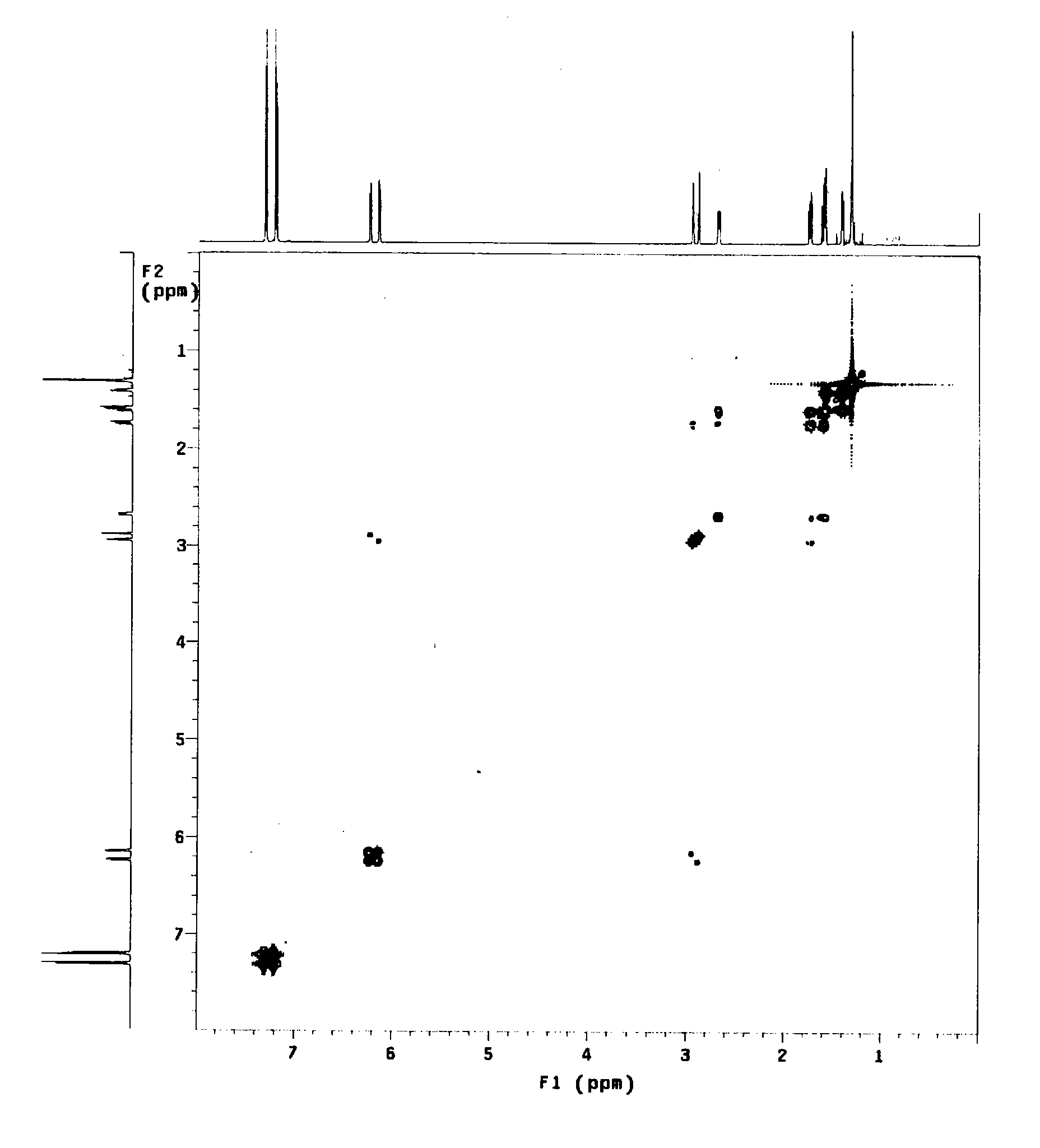

Method of recovering cumene

InactiveUS6900364B2Effective recoveryHydrocarbon by isomerisationHydrocarbon by polyaryl split-offOrganic chemistryCumene

A process for recovering cumene, characterized by subjecting 2,3-dimethyl-2,3-diphenylbutane produced in a process in which cumene is used, to hydrogenolysis in the presence of a catalyst thereby to convert it into cumene, and recovering the cumene.

Owner:SUMITOMO CHEM CO LTD

Catalyst for producing monocyclic aromatic hydrocarbon and production method of monocyclic aromatic hydrocarbon

ActiveUS9815047B2High yieldReduce yieldHydrocarbon by isomerisationCatalytic crackingCarbon numberPolycyclic aromatic hydrocarbon

The catalyst for producing aromatic hydrocarbon is for producing monocyclic aromatic hydrocarbon having 6 to 8 carbon number from oil feedstock having a 10 volume % distillation temperature of 140° C. or higher and a 90 volume % distillation temperature of 380° C. or lower and contains crystalline aluminosilicate and phosphorus. A molar ratio (P / Al ratio) between phosphorus contained in the crystalline aluminosilicate and aluminum of the crystalline aluminosilicate is from 0.1 to 1.0. The production method of monocyclic aromatic hydrocarbon is a method of bringing oil feedstock having a 10 volume % distillation temperature of 140° C. or higher and a 90 volume % distillation temperature of 380° C. or lower into contact with the catalyst for producing monocyclic aromatic hydrocarbon.

Owner:JX NIPPON OIL & ENERGY CORP

Catalyst for producing monocyclic aromatic hydrocarbons and production method of monocyclic aromatic hydrocarbons

InactiveUS20130281755A1High yieldHydrocarbon by isomerisationCatalytic crackingCarbon numberRare-earth element

The catalyst for producing monocyclic aromatic hydrocarbons is for producing monocyclic aromatic hydrocarbons having 6 to 8 carbon number from oil feedstock having a 10 volume % distillation temperature of 140° C. or higher and a 90 volume % distillation temperature of 380° C. or lower. The catalyst contains crystalline aluminosilicate and a rare earth element, in which the amount of the rare earth element expressed in terms of the element is 0.1 to 10 mass % based on the crystalline aluminosilicate. In the production method of monocyclic aromatic hydrocarbons, oil feed stock having a 10 volume % distillation temperature of 140° C. or higher and a 90 volume % distillation temperature of 380° C. or lower is brought into contact with the catalyst for producing monocyclic aromatic hydrocarbons.

Owner:JX NIPPON OIL & ENERGY CORP

Catalyst for producing monocyclic aromatic hydrocarbons, and method for producing monocyclic aromatic hydrocarbons

InactiveUS20140364666A1High yieldHydrocarbon by isomerisationCatalytic crackingCarbon numberDistillation

A catalyst for producing monocyclic aromatic hydrocarbons, used for producing monocyclic aromatic hydrocarbons of 6 to 8 carbon number from a feedstock oil having a 10 volume % distillation temperature of at least 140° C. and an end point temperature of not more than 400° C., wherein the catalyst contains a crystalline aluminosilicate, gallium and / or zinc, and phosphorus, the molar ratio between silicon and aluminum (Si / Al ratio) in the crystalline aluminosilicate is not more than 100, the molar ratio between the phosphorus supported on the crystalline aluminosilicate and the aluminum of the crystalline aluminosilicate (P / Al ratio) is not less than 0.01 and not more than 1.0, and the amount of gallium and / or zinc is not more than 1.2% by mass based on the mass of the crystalline aluminosilicate.

Owner:JX NIPPON OIL & ENERGY CORP

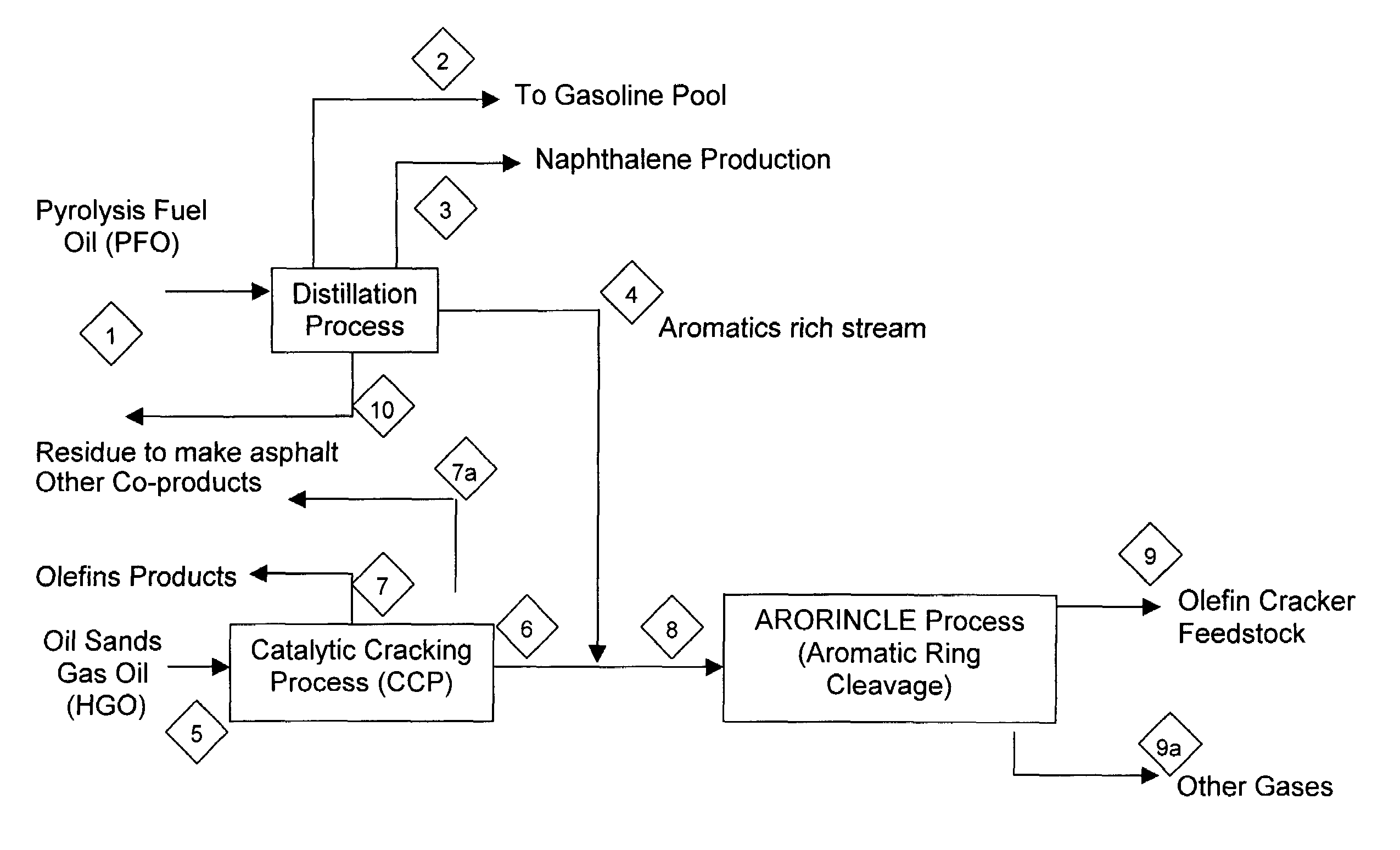

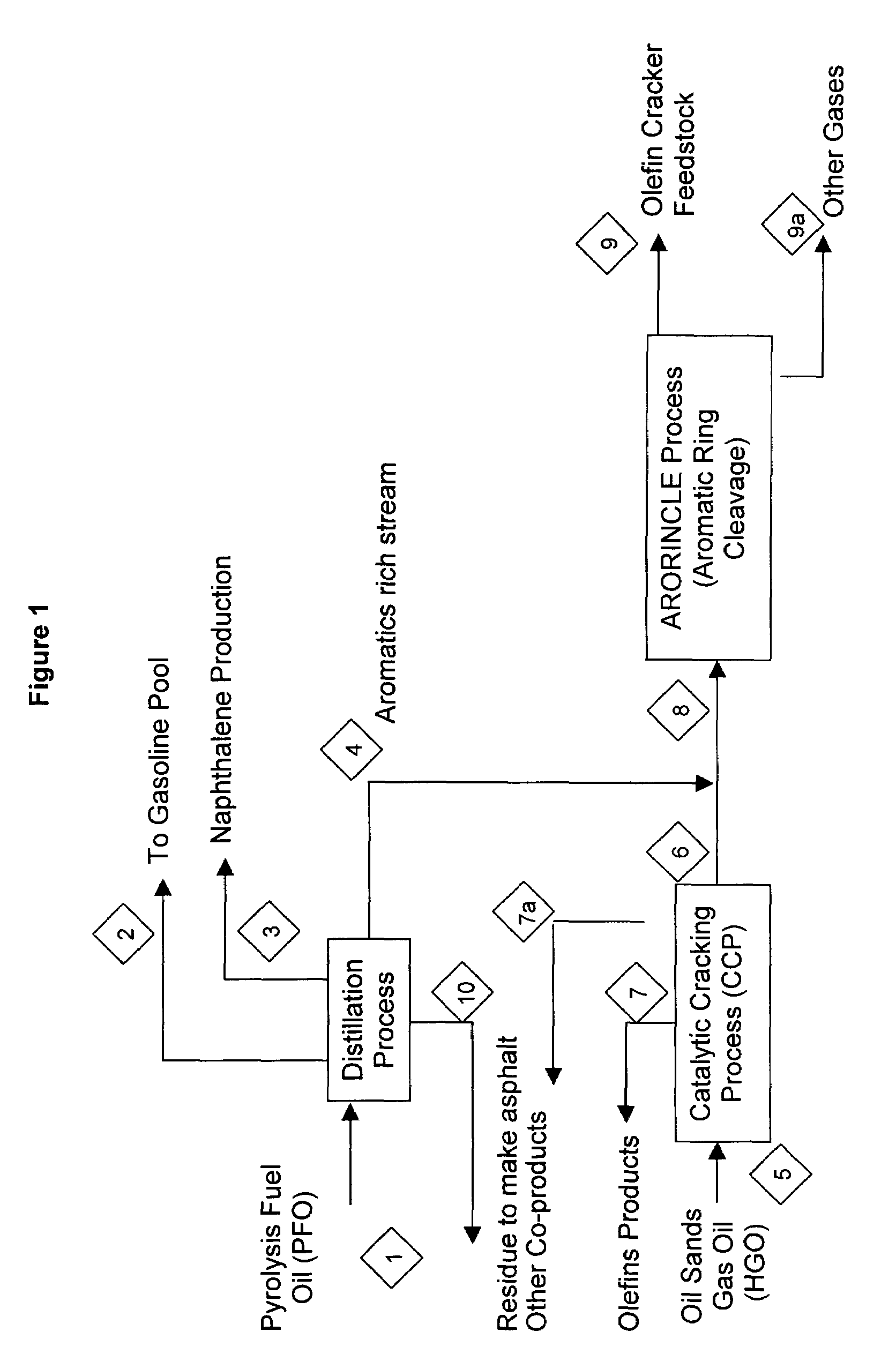

Integrated process to convert heavy oils from oil sands to petrochemical feedstock

An aromatics / naphthalene rich stream obtained by processing heavy gas oil derived from tar sands and cycle oils derived from cracking heavy gas oil may optionally be blended and subjected to a hydrogenation process and a ring opening reaction typically in the presence of a zeolite, alumina, or silica alumina based catalyst which may contain noble metals and or copper or molybdenum to produce paraffinic feedstocks for further chemical processing.

Owner:NOVA CHEM (INT) SA

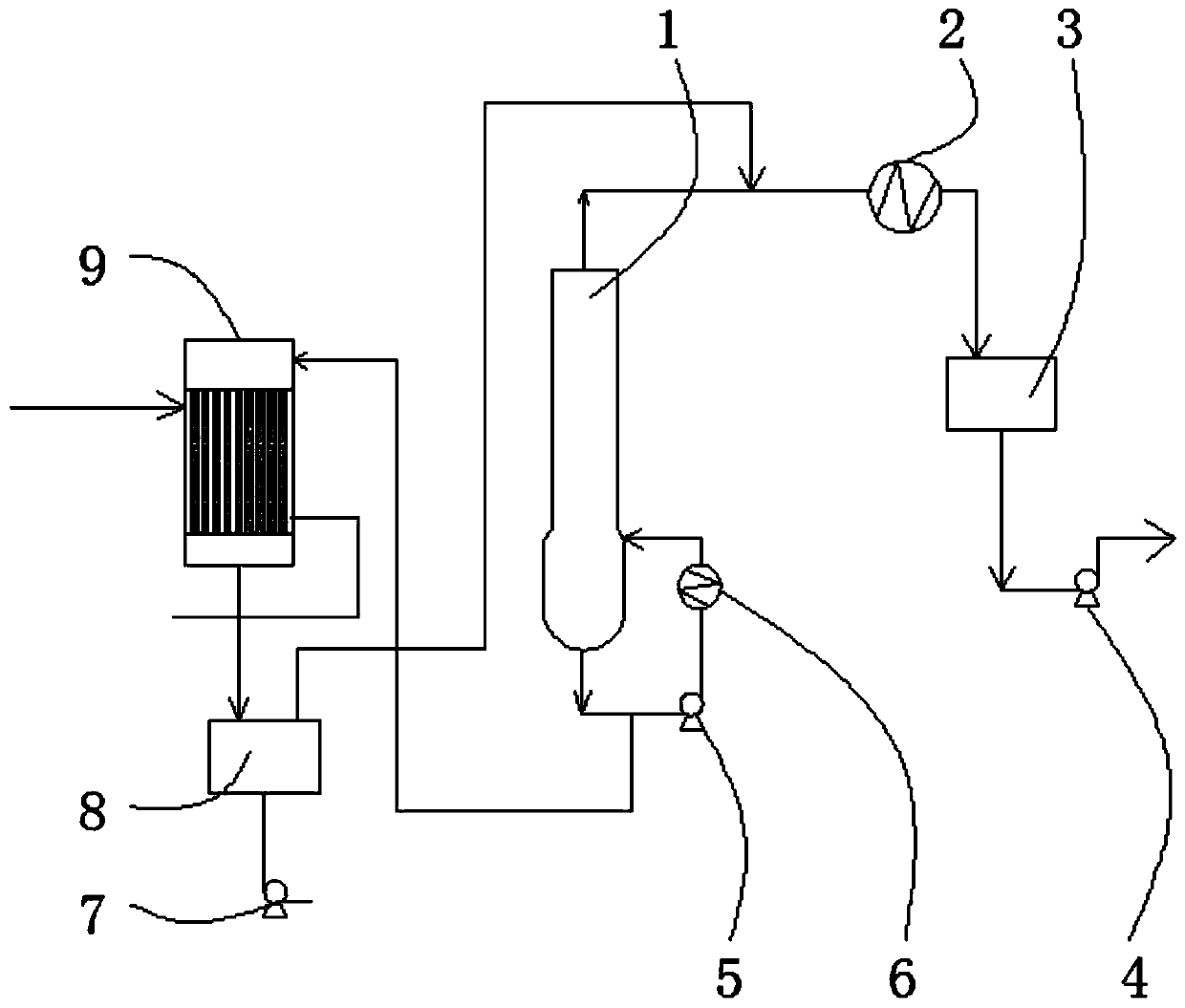

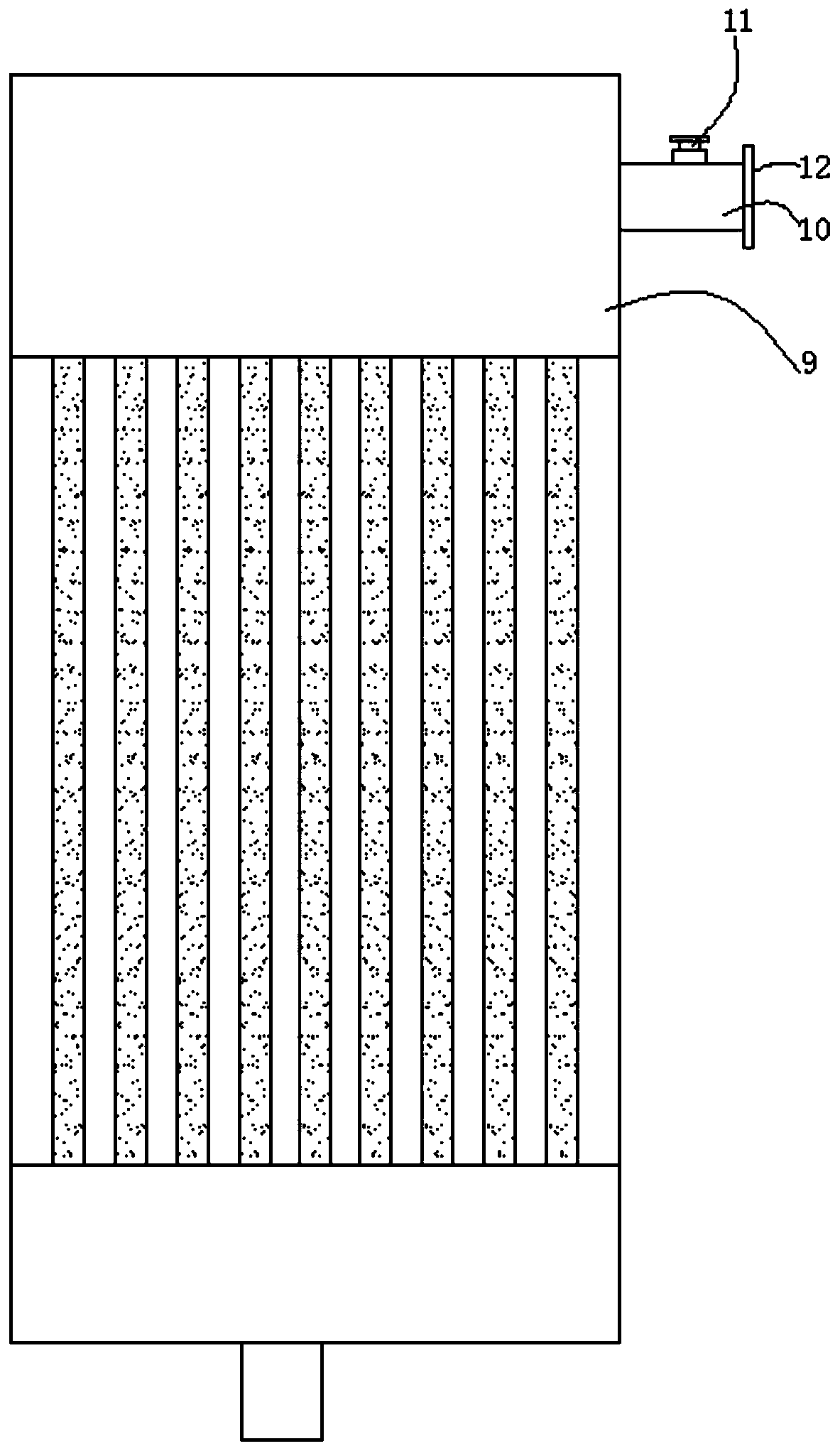

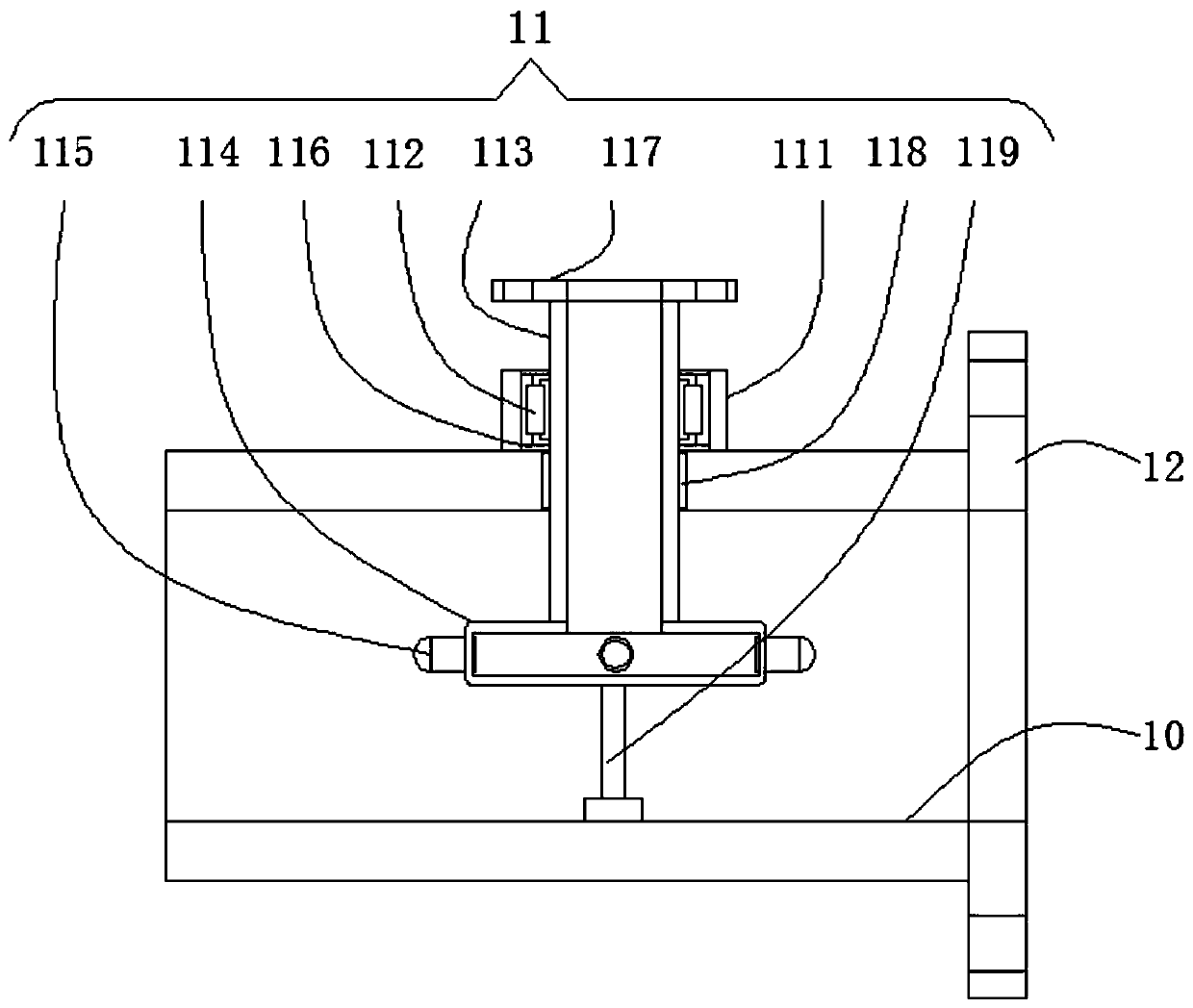

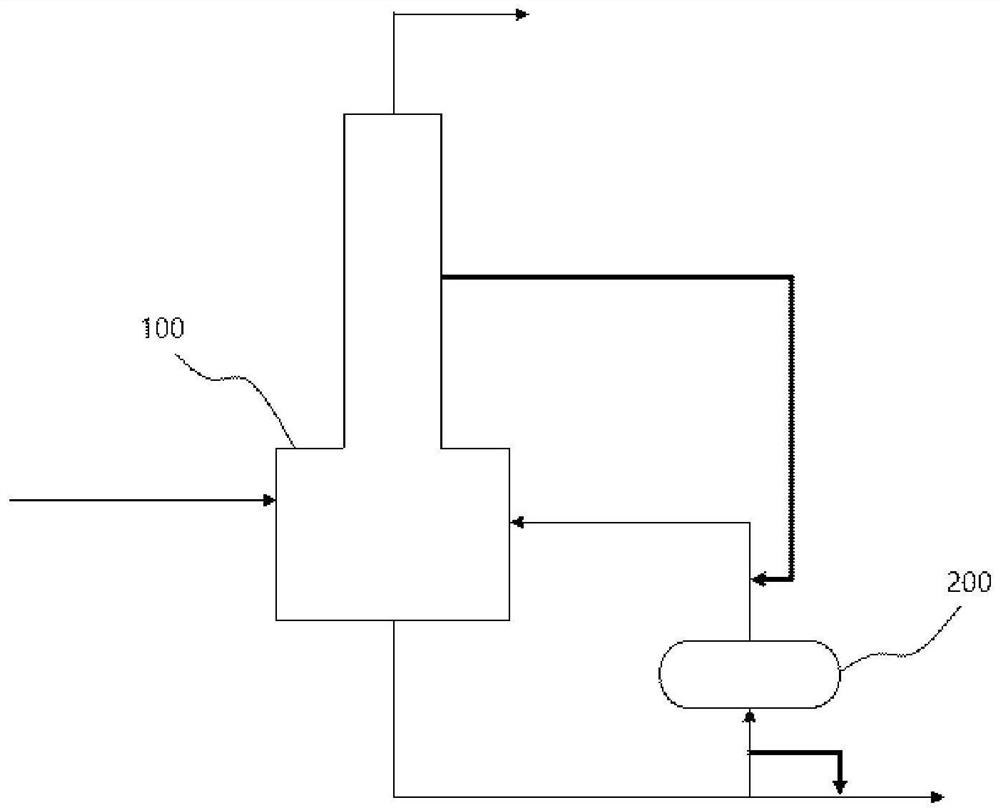

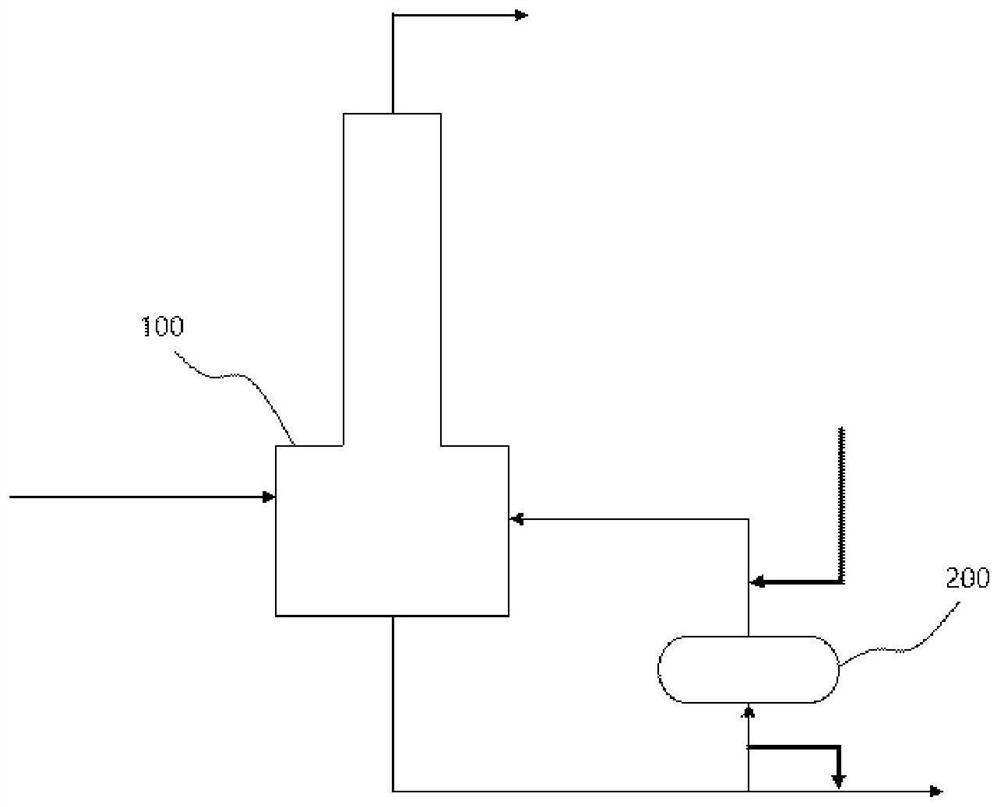

System for recovering effective components in styrene byproduct tar

PendingCN111056905AReduce lossImprove the recovery rate of effective componentsDistillation purification/separationHydrocarbon by polyarylsubstituted aliphatic compound split-offPolystyreneProcess engineering

The invention provides a system for recovering effective components in styrene byproduct tar. The system for recovering the effective components in the styrene byproduct tar comprises a rectifying tower, a tower top condenser, a recovery tank and a tower kettle pump; the tower top condenser is communicated with the top of the rectifying tower through a conveying pipe; the recovery tank is communicated with the output end of the tower top condenser through a connecting pipe, and one side of the recovery tank is communicated with the input end of a recovery pump through a conveying pipe; the input end of the tower kettle pump is communicated with the bottom end of the rectifying tower through a connecting pipe. The system for recovering the effective components in styrene byproduct tar has amethod for preparing monomer styrene through catalytic cracking of tar negative pressure rectification coupled tower kettle circulating tar. 90% or more of effective components (styrene and polystyrene) in the styrene by-product tar can be separated, and the material loss of the styrene component in the by-product can be reduced.

Owner:ANHUI HAOYUAN CHEM IND GRP

A method for reducing the unit consumption of cumene in the process of producing propylene oxide by co-oxidation of cumene

ActiveCN112250534BReduce unit consumptionCatalyst supports are readily available and cheapHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlcoholProcess engineering

The invention discloses a method for reducing the unit consumption of cumene in the process of producing propylene oxide by a cumene co-oxidation method. In the process of producing propylene oxide by co-oxidation of cumene, heavy components such as cumene are produced by hydrogenolysis of dimethylbenzyl alcohol to prepare cumene. The invention converts the heavy component into cumene for recycling and reuse through two steps of thermal cracking and catalytic hydrogenation, and significantly improves the economy and competitiveness of the cumene co-oxidation method for producing propylene oxide.

Owner:WANHUA CHEM GRP CO LTD

Aromatics hydrogenolysis using novel mesoporous catalyst system

InactiveUS7608747B2Improve accessibilityHydrocarbon by isomerisationHydrocarbon by polyaryl split-offArylMetal

Owner:ABB LUMMUS GLOBAL INC

A method for directly preparing supported solid superacid catalyst by microwave method

ActiveCN102614926BHigh catalytic hydrocracking activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationTrimethylsilyl trifluoromethanesulfonateMicrowave method

The invention relates to a method for preparing a loaded solid super acidic catalyst directly by a microwave method, and belongs to a method for preparing a super acidic catalyst. The method comprises the following steps of: (1) mixing and stirring NaHCO3 and a carbon nano tube in a weight ratio of 1:500 fully, and roasting in a microwave reactor to obtain a Na-loaded catalyst carrier; (2) heating the Na-loaded catalyst carrier by microwave radiation, adding a mixed solution of antimony pentachloride (SbCl5) and trimethylsilyl trifluoromethanesulfonate (F3CSO3Si(CH3)3) dropwise, stirring and immersing to obtain a suspension mixed solution; (3) filtering the suspension mixed solution to obtain a solid precursor and a mixed solution; (4) putting the solid precursor into the microwave reactor, heating by the microwave radiation, and roasting to obtain a solid super acidic catalyst prototype; and (5) performing operation for 1 to 5 times by taking the solid super acidic catalyst prototype as a raw material according to the steps (2), (3) and (4) to obtain the solid-loaded super acidic catalyst. The method has the advantages that: the loaded solid super acidic catalyst prepared by the microwave method is high in catalytic hydrocracking activity and selectivity.

Owner:CHINA UNIV OF MINING & TECH

Method for producing norbornene derivative

InactiveUS20100197970A1High yieldEasy to produceHydrocarbon by isomerisationOrganic compound preparationHydrogen atomPalladium

A method for producing a norbornene derivative wherein,in the presence of palladium and at least one selected from phosphorus compounds represented by the following General Formulae (1) and (2):[in Formula (1), R1, R2, R3 and R4 each independently represent a hydrogen atom or the like, and R5 and R6 each independently represent a branched chain saturated hydrocarbon group having 3 to 10 carbon atoms or the like], and[in Formula (2), R7 represents a branched chain saturated hydrocarbon group having 3 to 10 carbon atoms],a norbornadiene derivative represented by the following General Formula (3):[in Formula (3), R8, R9, R10, R11 and R12 each independently represent a hydrogen atom or the like, l represents an integer of 0 or 1, m represents an integer of 0 or 1, and n represents an integer of 0 or 1], and a bromine compound represented by the following General Formula (4):[Chemical Formula 4]Br—Z—R13 (4)[in Formula (4), Z represents a phenylene group or the like, and R13 represents a hydrogen atom or the like] are reacted with each other, to thereby obtain a norbornene derivative represented by the following General Formula (5):[in Formula (5), R14, R15, R16, R17 and R18 each independently represent a hydrogen atom or the like, Z represents a phenylene group or the like, R19 represents a hydrogen atom or the like, l represents an integer of 0 or 1, m represents an integer of 0 or 1, and n represents an integer of 0 or 1], the norbornene derivative having a configuration of a substituent represented by Z in General Formula (5) that is an exo configuration.

Owner:NIPPON OIL CORP

Production method of monocyclic aromatic hydrocarbons

ActiveUS20130281756A1Reduce contentHigh yieldHydrocarbon by isomerisationCatalytic crackingPolycyclic aromatic hydrocarbonDistillation

In the production method of monocyclic aromatic hydrocarbons, oil feedstock having a 10 volume % distillation temperature of 140° C. or higher and a 90 volume % distillation temperature of 380° C. or lower is brought into contact with a catalyst for producing monocyclic aromatic hydrocarbons that includes a mixture containing a first catalyst which contains crystalline aluminosilicate containing gallium and / or zinc and phosphorus and a second catalyst which contains crystalline aluminosilicate containing phosphorus.

Owner:JX NIPPON OIL & ENERGY CORP

Catalyst for producing monocyclic aromatic hydrocarbons, and method for producing monocyclic aromatic hydrocarbons

ActiveUS20140364667A1High yieldPrevention of any deterioration over timeHydrocarbon by isomerisationMolecular sieve catalystsCarbon numberDistillation

A catalyst for producing monocyclic aromatic hydrocarbons of 6 to 8 carbon number from a feedstock oil having a 10 volume % distillation temperature of at least 140° C. and an end point temperature of not more than 400° C., or a feedstock oil having a 10 volume % distillation temperature of at least 140° C. and a 90 volume % distillation temperature of not more than 360° C., wherein the catalyst contains a crystalline aluminosilicate, gallium and / or zinc, and phosphorus, and the amount of phosphorus supported on the crystalline aluminosilicate is within a range from 0.1 to 1.9% by mass based on the mass of the crystalline aluminosilicate; and a method for producing monocyclic aromatic hydrocarbons, the method involving bringing a feedstock oil having a 10 volume % distillation temperature of at least 140° C. and an end point temperature of not more than 400° C., or a feedstock oil having a 10 volume % distillation temperature of at least 140° C. and a 90 volume % distillation temperature of not more than 360° C., into contact with the above-mentioned catalyst for producing monocyclic aromatic hydrocarbons.

Owner:JXTG NIPPON OIL & ENERGY CORPORATION

Multi-channel pyrolysis tubes, material deposition equipment including the same and associated methods

InactiveUS20160325264A1Efficient heatingEasy to useLiquid surface applicatorsChemical/physical/physico-chemical stationary reactorsBiomedical engineeringPyrolysis

A pyrolysis tube for use with a material deposition system includes a plurality of channels. The channels may be defined by internal elements of the pyrolysis tube, or by internal elements that form an insert for a conventionally configured pyrolysis tube. One or more of the channels may extend straight through the pyrolysis tube, providing a direct line of sight through the pyrolysis tube. Material deposition systems that include such an insert or pyrolysis tube are also disclosed, as are methods for efficiently pyrolyzing precursor materials at temperatures that are reduced relative to conventional pyrolysis temperatures and / or at rates that are increased relative to conventional pyrolysis rates.

Owner:HZO INC

Methods for forming ethylbenzene from polystyrene

ActiveUS10913694B2Good choiceEfficient CatalysisCatalystsHydrocarbon preparation catalystsPtru catalystPolystyrene

According to one or more embodiments presently disclosed, a method of catalytically converting polystyrene may include contacting polystyrene with a catalyst to form a product comprising ethylbenzene. The catalyst may include oxidized iron, oxidized cobalt, and oxidized copper. The catalyst may further include a mesoporous support material with pores having an average pore diameter of from 2 nm to 50 nm.

Owner:KING ABDULLAH UNIV OF SCI & TECH +1

Method for decomposing phenolic by-products

ActiveCN113382979AReduce contentSpeed up dismantlingGas treatmentOrganic compound preparationEnvironmental engineeringActive ingredient

The present invention relates to a method for decomposing phenolic by-products and, more specifically, provides a method for decomposing phenolic by-products, the method comprising the steps: supplying a phenolic by-product stream to a decomposing device to thermally decompose the stream (S10); recovering active ingredients from an upper discharge stream of the decomposing device and discharging high-boiling point materials from a lower discharge stream (S20); supplying a portion of the lower discharge stream of the decomposing device through a reboiler to the decomposing device, and discharging the remainder of the stream (S30); and supplying a side discharge stream of the decomposing device to the reboiler (S40).

Owner:LG CHEM LTD

Popular searches

Hydrocarbon by hydrogenation Catalytic naphtha reforming Hydrocarbon by saturated bond conversion Treatment with hydrotreatment processes Hydrocarbon from saturated and unsaturated hydrocarbon addition Refining to eliminate hetero atoms Hydrocarbons from unsaturated hydrocarbon addition Hydrocarbon oil cracking Hydrocarbon oils treatment products Hydrocarbon oil cracking process

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com