Laser cladding repair equipment and method for irregular curved surfaces of Invar alloy molds

A laser cladding, irregular technology, applied in the direction of metal material coating process, coating, etc., can solve problems such as unqualified, reduce production costs, good shape and performance matching, reduce residual stress and deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

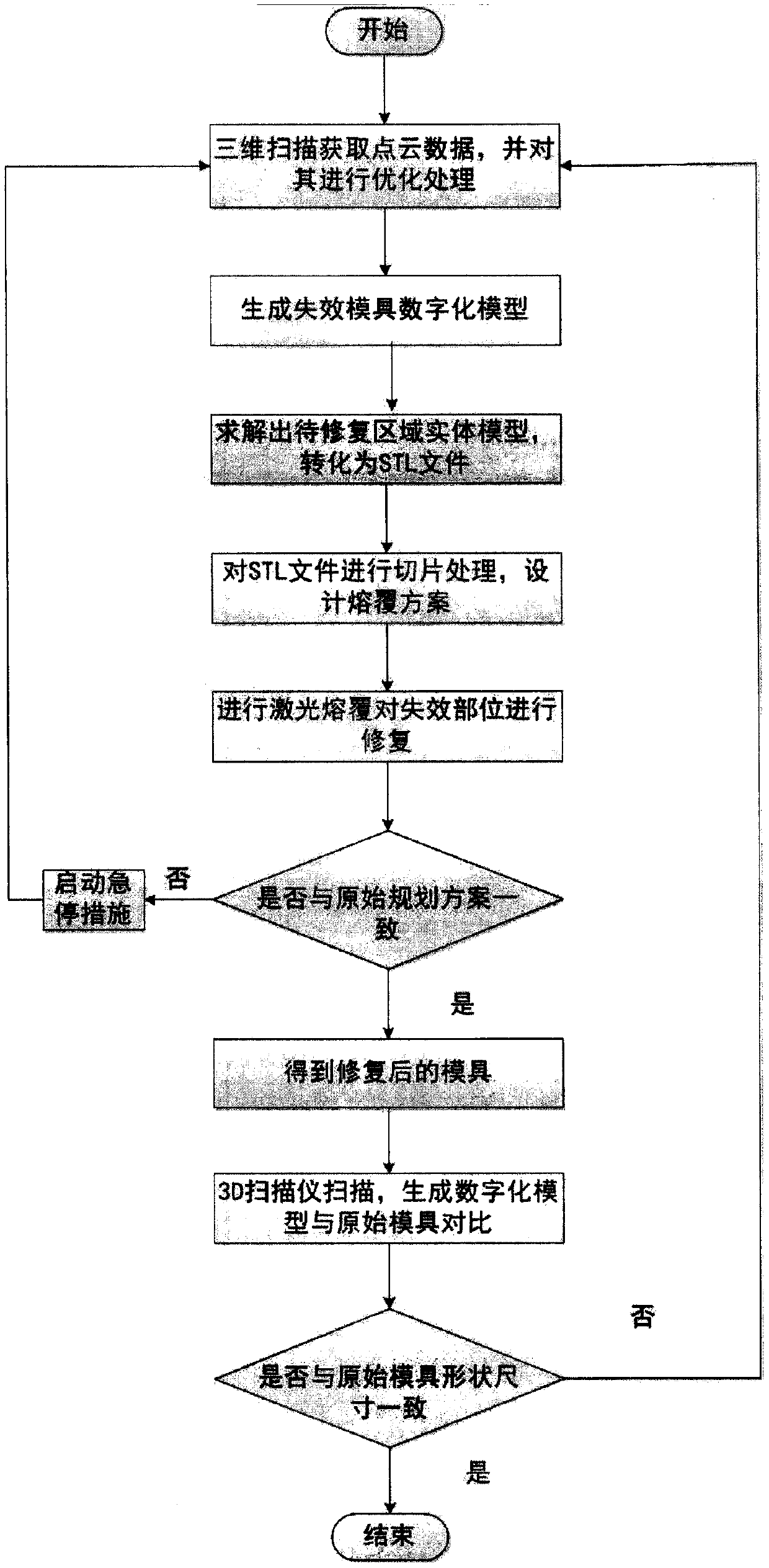

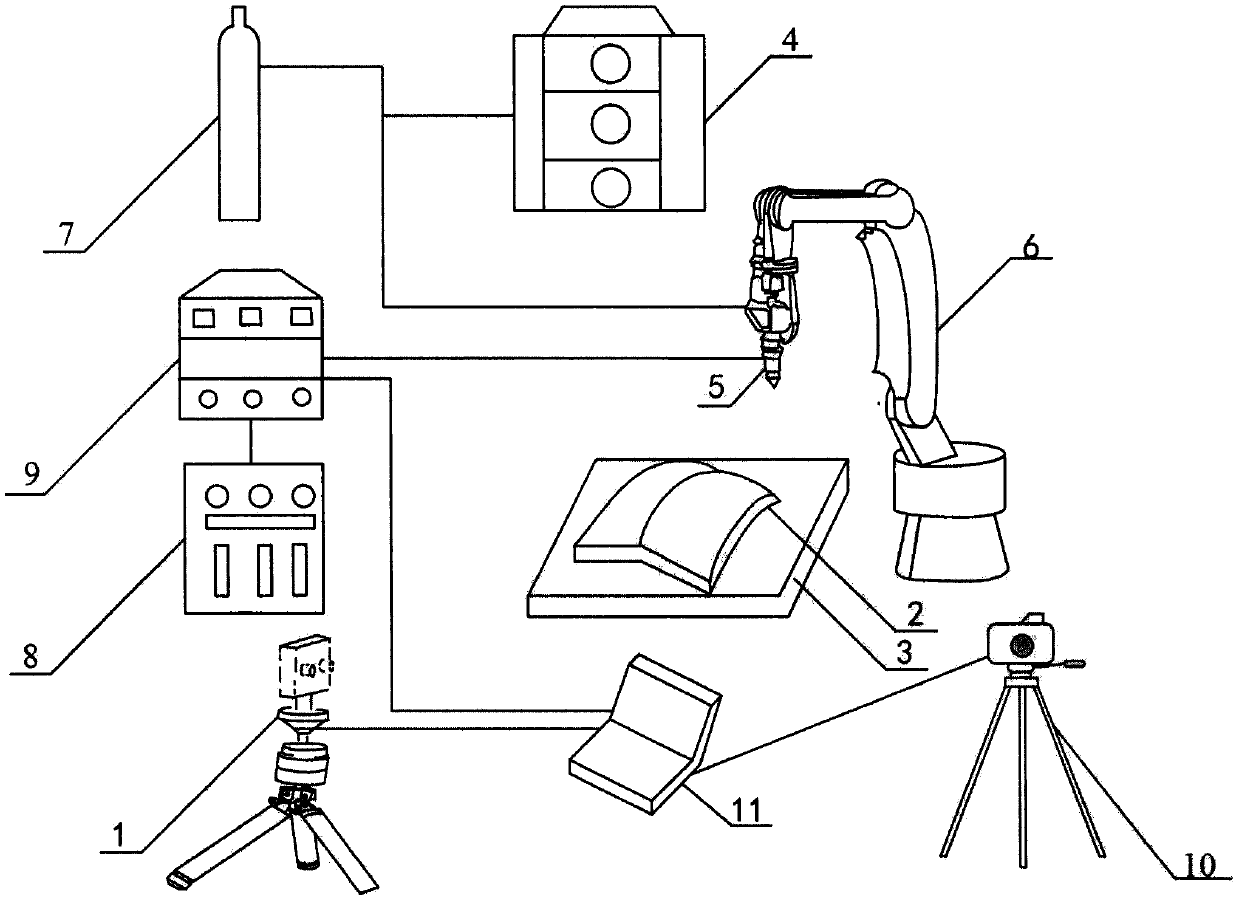

[0023] The present invention will be further described below in conjunction with the accompanying drawings. A laser cladding repair equipment and method for irregular curved surfaces of Invar alloy molds, characterized in that the method includes the following steps:

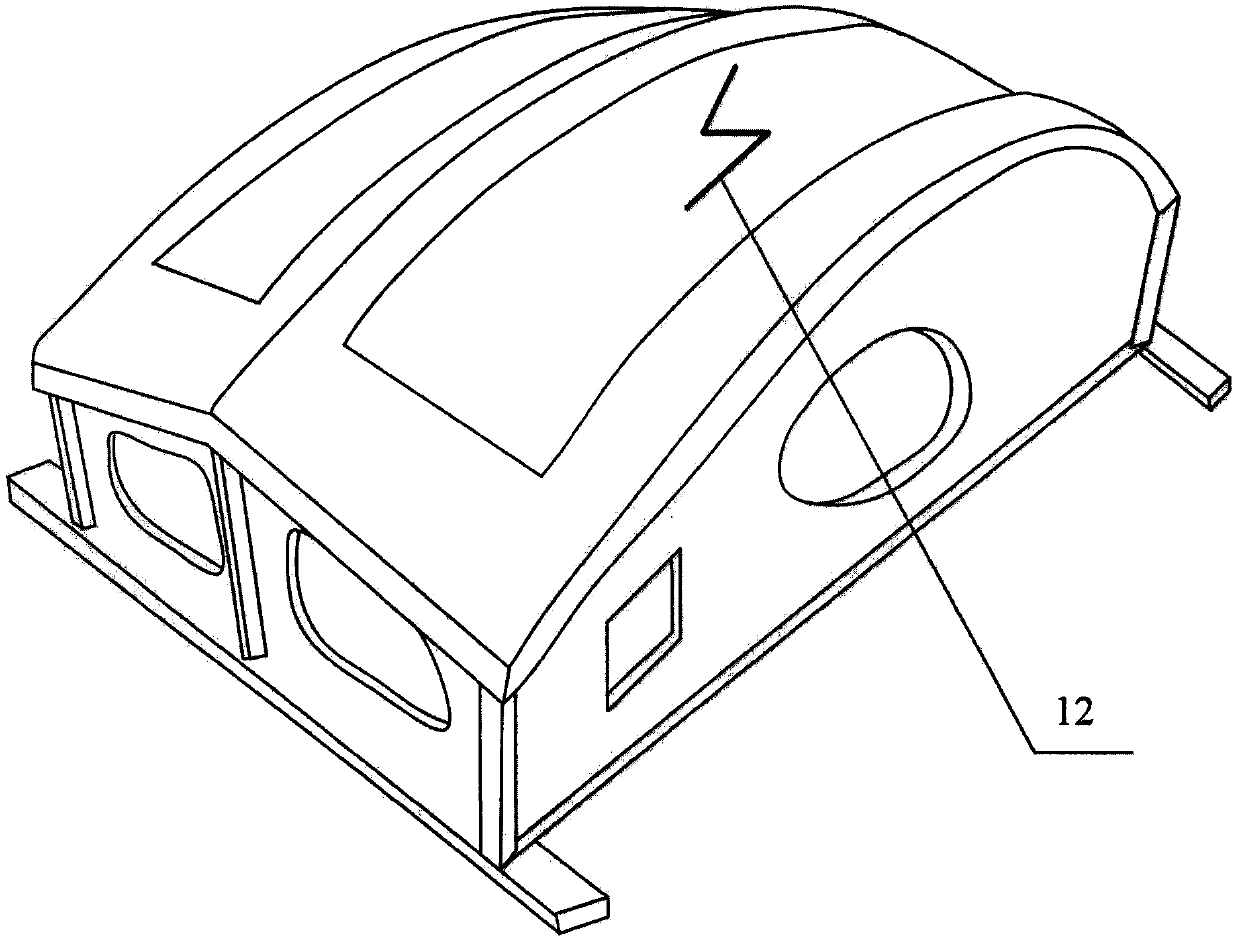

[0024] For the irregular Invar alloy mold surface 3 whose size is 40mm high, 120mm long, and 120mm wide. Clean it first: finely process the sample with grinding equipment to remove surface oil, rust and other impurities, use acetone to clean the workpiece to completely remove the surface oil, and then wipe the workpiece with alcohol until the alcohol evaporates. The cladding powder used is Invar alloy spherical powder, which is obtained by ball milling Invar alloy rods, and its particle size is between 50 μm and 150 μm.

[0025] Connect and debug the 3D laser scanner 1 with the software measurement system (Polyworks) in the model generation module of the area to be repaired, use the 3D scanner to measure the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com