Compound feed for laying hens in early brood stages and preparation method thereof

A technology of compound feed and laying hens, applied in animal feed, animal feed, bacteria used in food preparation, etc., can solve the problem of poor intestinal health and body health, poor division of chicken feed stages, and inability to ensure nutrition and nutrients Food intake, digestion and absorption, etc., to achieve good intestinal health, improve disease resistance, and improve utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The early stage compound feed for laying hens provided in Example 1, in parts by weight, includes: 390 parts of corn flour, 30 parts of rice syrup, 30 parts of sterile water, 20 parts of oil, 18 parts of flour, 7 parts of fragrant tea root powder 3 parts of emulsifier, 2 parts of corn hydrolyzate, 0.6 part of synthetic amino acid, 0.05 part of compound enzyme preparation, 0.05 part of prebiotic.

[0023] The fragrant tea vegetable root powder is that the root of the fragrant tea vegetable is washed, aired, dried, and ground into powder, and the size of the powdery fragrant tea vegetable root powder is 300 mesh. The rice syrup is rice syrup with a solid content of 60%. The sterile water is dechlorinated distilled water, the emulsifier is sodium tyrosinate, the fat is animal oil and / or vegetable oil, the animal oil is lard, and the vegetable oil is soybean oil.

[0024] The synthetic amino acid comprises the composition of lysine, methionine and threonine; the parts by w...

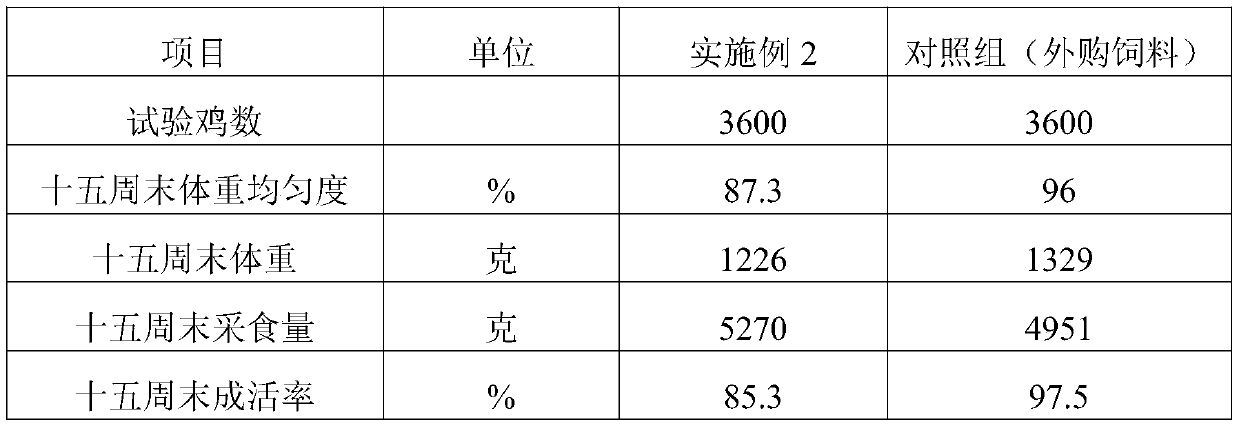

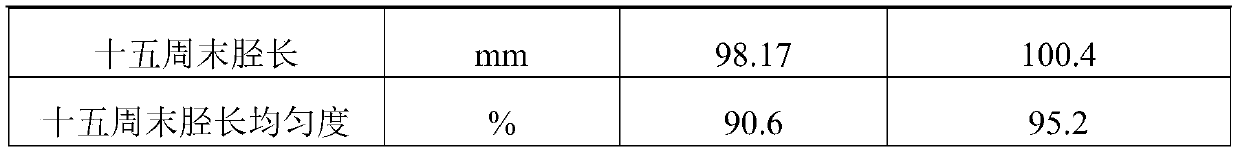

Embodiment 2

[0028] The early stage compound feed for laying hens provided by the present embodiment 2, in parts by weight, includes: 380 parts of corn flour, 25 parts of rice syrup, 32 parts of sterile water, 22 parts of oil, 16 parts of flour, 6 parts of fragrant tea vegetable root powder 2 parts of emulsifier, 3 parts of corn hydrolyzate, 0.5 part of synthetic amino acid, 0.06 part of compound enzyme preparation, 0.06 part of prebiotic.

[0029] The fragrant tea vegetable root powder is that the root of the fragrant tea vegetable is washed, aired, dried, and ground into powder, and the size of the powdery fragrant tea vegetable root powder is 300 mesh. The rice syrup is rice syrup with a solid content of 60%. The sterile water is dechlorinated distilled water, the emulsifier is sodium tyrosinate, the fat is animal oil and / or vegetable oil, the animal oil is lard, and the vegetable oil is soybean oil.

[0030] The synthetic amino acid comprises the composition of lysine, methionine and ...

Embodiment 3

[0034] The preparation method of the laying hen early stage compound feed that present embodiment 3 provides, comprises the following steps:

[0035] Step 1: 390 parts of corn flour, 18 parts of flour, crushed and mixed evenly;

[0036] Step 2: Add 30 parts of rice syrup, 30 parts of sterile water, 20 parts of oil, 2 parts of corn hydrolyzed protein, 0.6 part of synthetic amino acid, 0.05 part of compound enzyme preparation and 0.05 part of prebiotic into the mixing tank medium fusion;

[0037] Step 3: Add 3 parts of emulsifier to stir and emulsify, then use a shear emulsification pump to shear at a speed of 3600 rpm or more, and then use a high-pressure homogenizer to homogenize at a homogenizing pressure of 60Mpa after shearing, and the emulsification is even Pasteurization is then carried out at a temperature of 62°C for 3.5 minutes, and then the material is sent to a spray tower with a pressure of 20Mpa for spray drying, and finally the material is collected and quantitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com