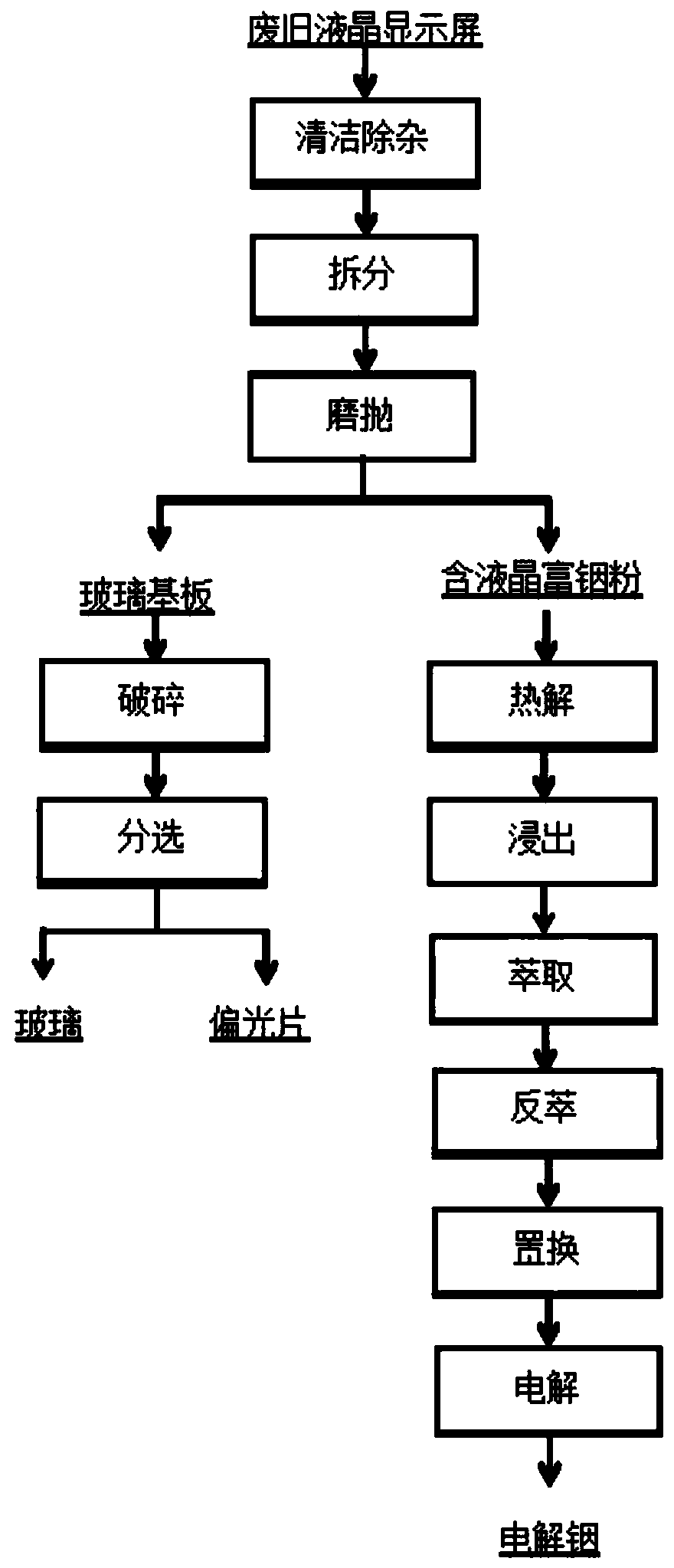

Waste liquid crystal display screen resource comprehensive recycling method

A liquid crystal display and liquid crystal display panel technology, which is used in the removal of solid waste, the improvement of process efficiency, and the photography process, etc. The effect of low workload, reduced material volume, and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

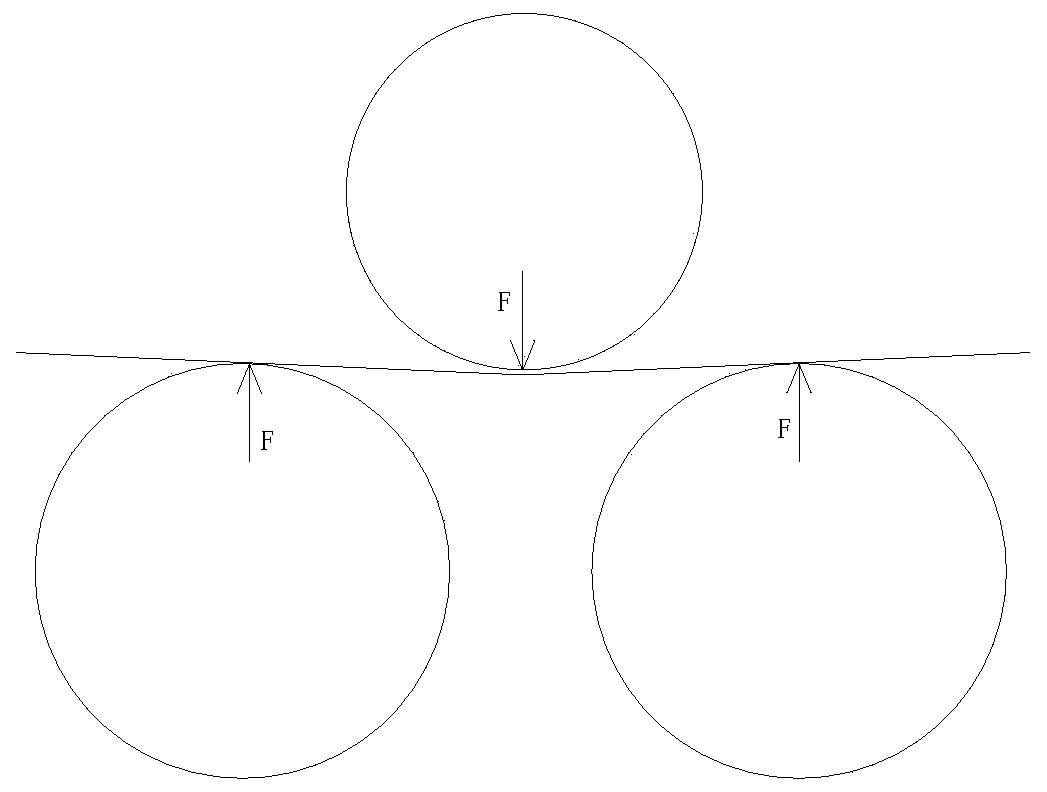

[0054] A. Pass the waste liquid crystal screen to be dismantled through such as figure 2 In the three-roll bending machine shown, the surface of each roller is covered with a rubber layer with a thickness of 20.0mm. The speed of the two driving rollers is 5m / min. Bending external forces in different directions are applied to the two sides to form Make the tension of different deformations between the two panels bonded to each other, make the sealing glue of the bonded panels invalid, realize the separation of the two panels of the liquid crystal display, and obtain the liquid crystal display panel with the exposed liquid crystal surface, and the separation of the liquid crystal display panel The rate reaches 95%;

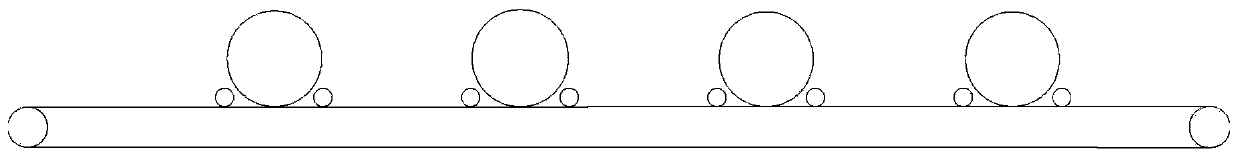

[0055] B. Pass the liquid crystal display panel with the exposed liquid crystal surface obtained in step A through the milling equipment conveyed by a belt, grind and polish off the liquid crystal layer and the ITO indium layer, and collect it under a negative pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com