Preparation method of high-hardness silver-copper-nickel alloy conductive ring

A nickel alloy and conductive ring technology, applied in metal rolling, metal processing equipment, etc., can solve problems such as pits and pits, skin peeling, low yield, etc., to achieve high production efficiency, uniform material, and production arrangement flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

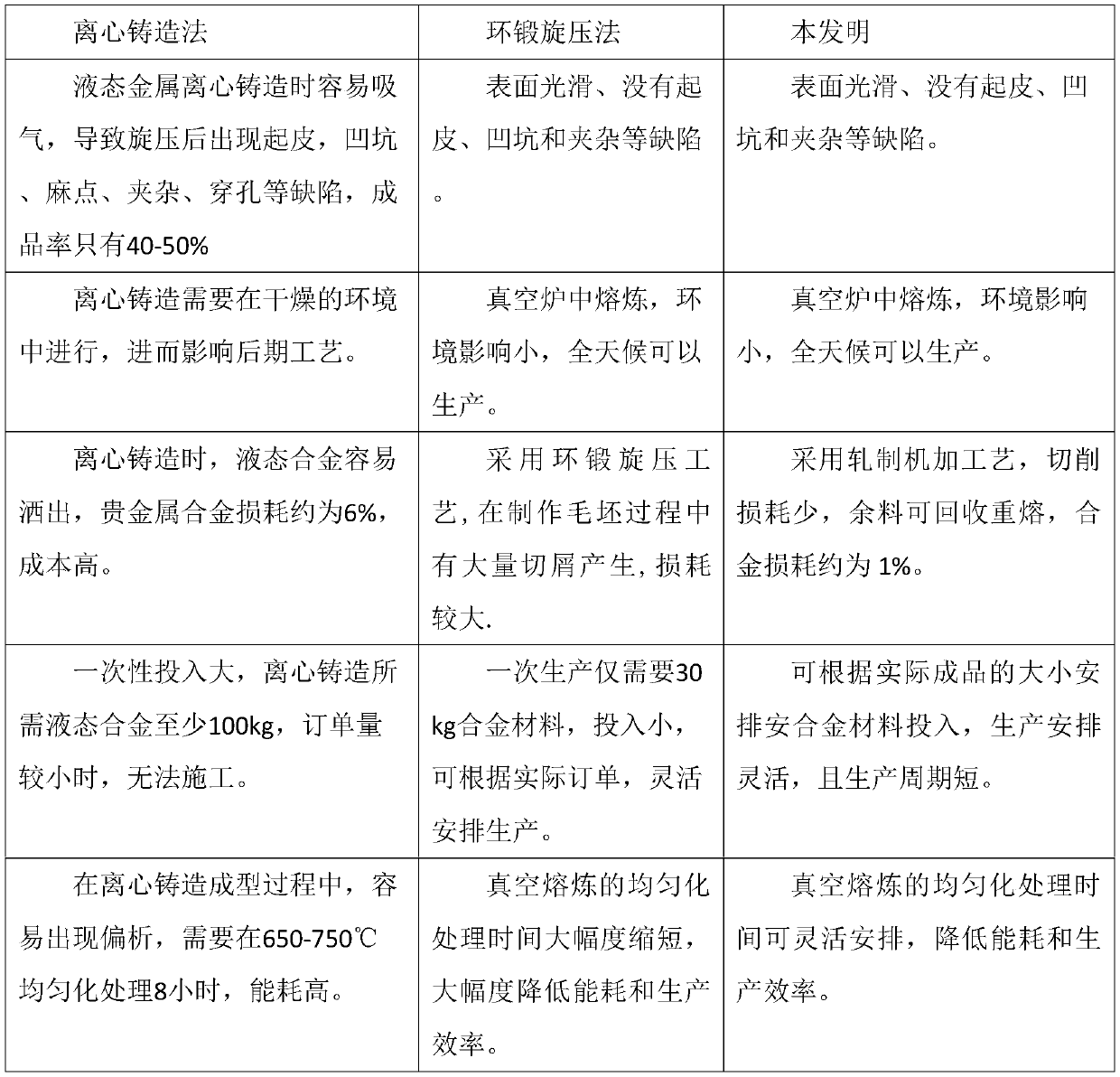

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Prepare the silver-copper-nickel alloy conductive ring according to the following steps:

[0026] (1) AgCuNi20-2 brand silver-copper-nickel alloy, according to the composition requirements of AgCuNi alloy, adopts split-type pure copper casting mold, and melts it in a vacuum intermediate frequency furnace. round ingot. The ingot was subjected to homogenization heat treatment at 745°C, and the holding time was 250min. The forging temperature of the ingot after heat treatment is 745°C, the final forging temperature is 590°C, the rest of the forging temperature is 650°C, the final forging temperature is 545°C, and the forging height is 30mm.

[0027] (2) rolling the billet obtained in step (1) on a rolling mill, the deformation amount of each pass is 20%, and returning to the furnace for annealing after each pass rolling, and rolling into a plate with a thickness of 10 mm. The rolling temperature is 660°C, and when it is lower than 550°C, return to the furnace for anneal...

Embodiment 2

[0031] Prepare the silver-copper-nickel alloy conductive ring according to the following steps:

[0032] (1) AgCuNi20-2 brand silver-copper-nickel alloy, according to the composition requirements of AgCuNi alloy, adopts split-type pure copper casting mold, and melts it in a vacuum intermediate frequency furnace. round ingot. The ingot was heat treated for homogenization at 650°C. The forging temperature of the ingot after heat treatment is 700°C, the final forging temperature is 550°C, the rest of the forging temperature is 620°C, the final forging temperature is 550°C, and the final forging height is 90mm.

[0033] (2) rolling the billet obtained in step (1) on a rolling mill, the pass deformation is 30%, and returning to the furnace for annealing after each pass rolling, and the rolling thickness is a 20mm plate. The rolling temperature is 680°C, and when it is lower than 580°C, return to the furnace for annealing, and the heat treatment process: hold at 680°C for 30 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Eccentricity | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com