Method and device for real-time detection and control of rotation of hollow stud welding arc

A real-time detection, stud welding technology, applied in the direction of electrode support device, cleaning method using liquid, arc welding equipment, etc., can solve the problems of non-welding, welding arc cannot be effectively rotated, etc., to achieve simple operation and improve welding success The effect of high rate and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take the welding of a Q235 hollow stud with a diameter of 20mm at a welding current of 800A and a magnetic field current of 0.34A as an example.

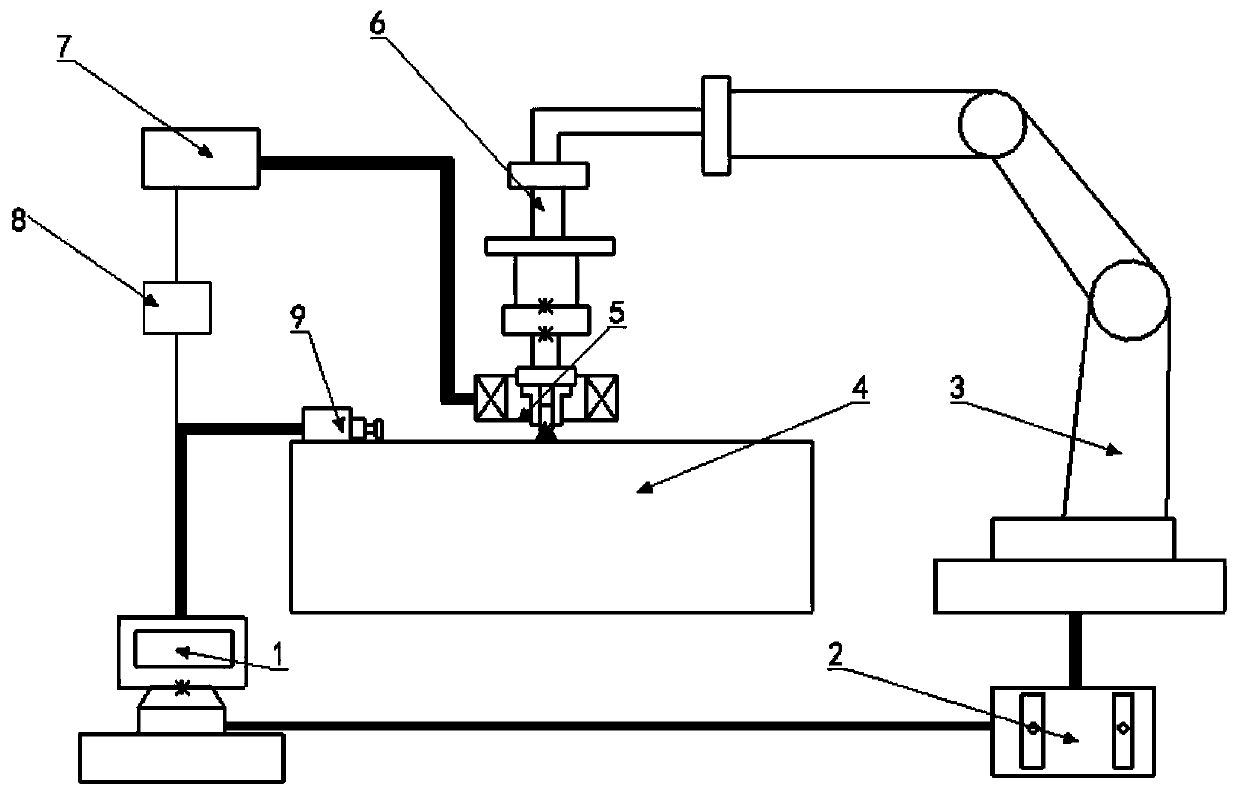

[0035] 1. Connect the stud welding robot, welding machine, magnetic field control power supply, CCD high-speed camera and computer according to the figure 2 The installation diagram shown completes the connection;

[0036] 2. Use fine sandpaper to polish the end face of the 20mm hollow stud to be welded and the base metal to be welded, and then clean it with acetone and dry it quickly;

[0037] 3. Start the automatic stud welding robot, control the robot to grip the stud to the welding position, control the welding torch to complete the preload, set the welding current to 800A, the welding time to 1450ms, the initial current of the magnetic field control power supply to 0.34A, and start the drawn arc welding torch for welding ;

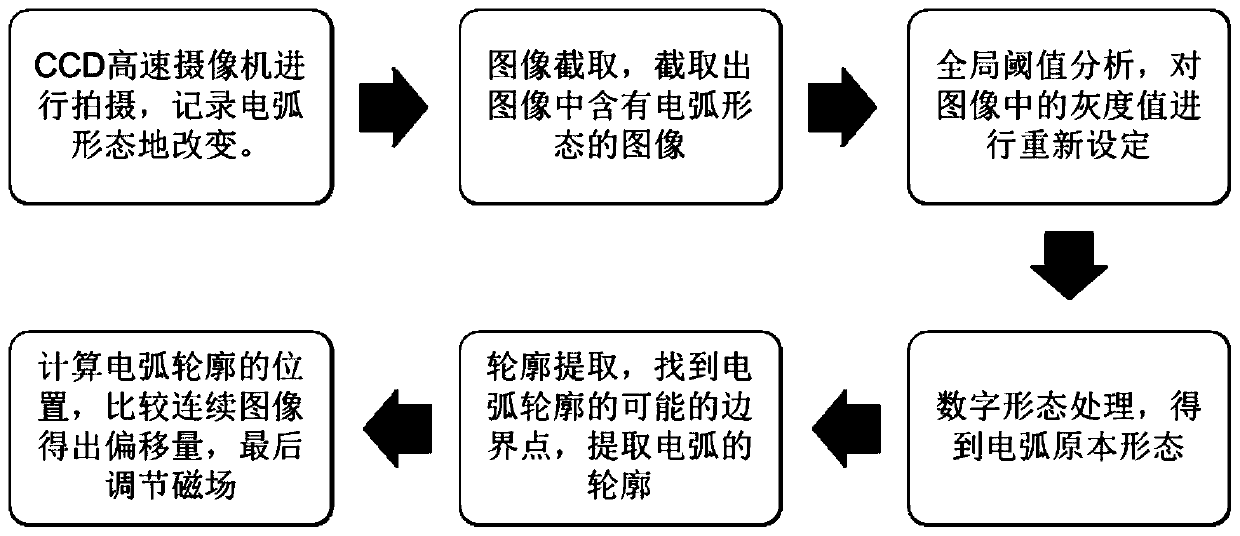

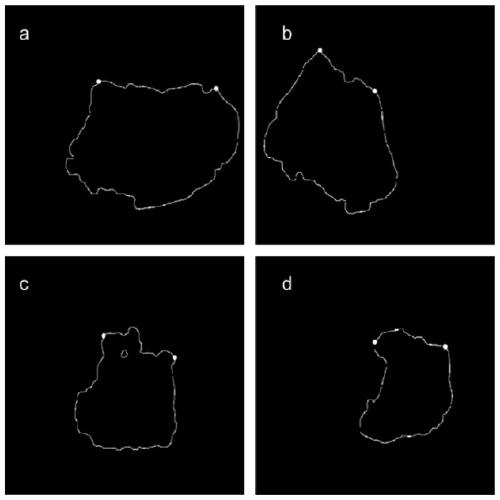

[0038] 4. During the welding process, the welding process is photographed by the CCD high-speed...

Embodiment 2

[0047] Take the welding of Q235 hollow studs with a diameter of 20mm under a magnetic field of 0.52A as an example.

[0048] 1. Connect the stud welding robot, welding machine, magnetic field control power supply, CCD high-speed camera and computer according to the figure 2 The installation diagram shown completes the connection;

[0049] 2. Grind the end face of the 20mm hollow stud and the base metal area to be welded with fine sandpaper, then clean it with acetone and dry it quickly;

[0050] 3. Start the automatic stud welding robot, control the robot to grip the stud to the welding position, control the welding torch to complete the preload, set the welding current to 900A, the welding time to 1450ms, the initial current of the magnetic field control power supply to 0.52A, and start the drawn arc welding torch for welding ;

[0051] 4. During the welding process, use the CCD high-speed camera to shoot the welding process, and set the shooting parameters of the CCD high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com