Production equipment of polyester fiber reinforced strip

A technology of polyester fiber and production equipment, applied in the field of polyester fiber processing, can solve the problems of increasing the molecular force between the mixture and the strip roll, increasing the melt index of polyethylene resin, etc., so as to improve the contact smoothness and reduce the coverage. , the effect of preventing backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

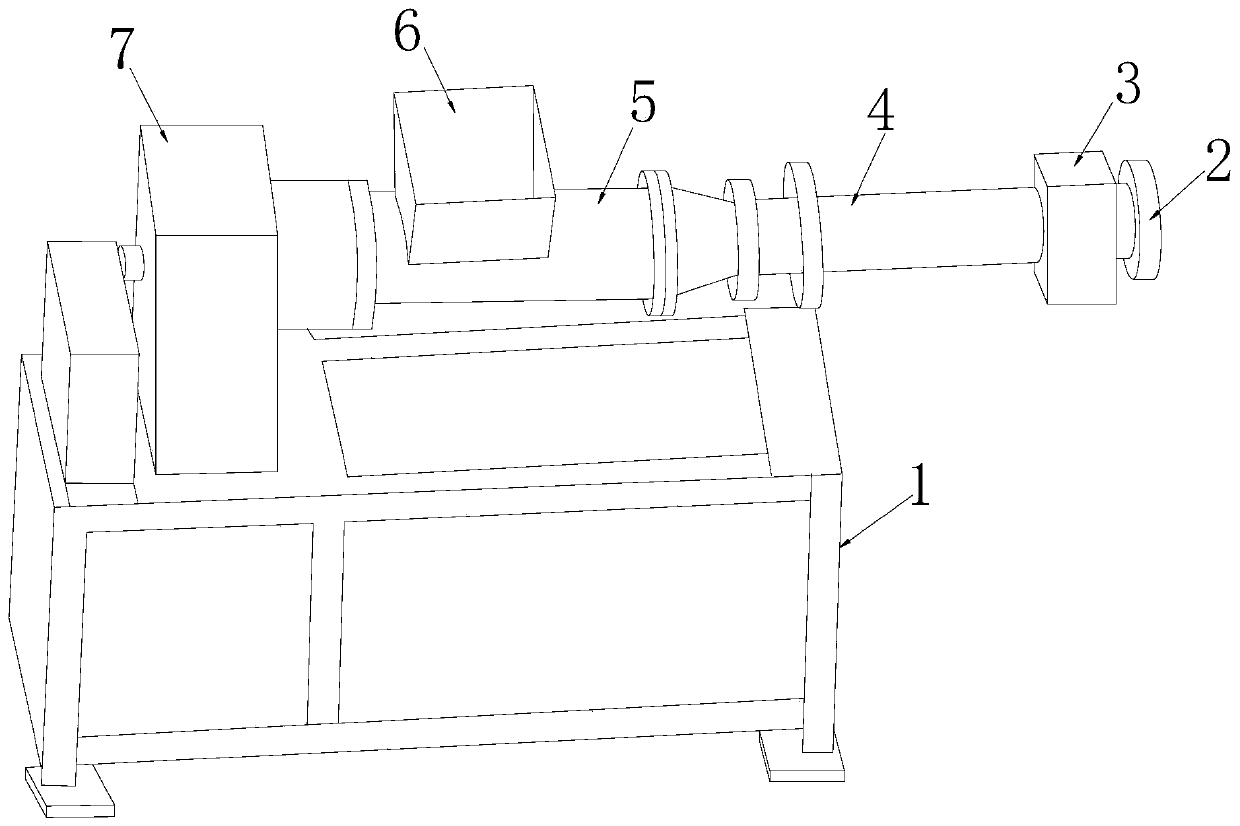

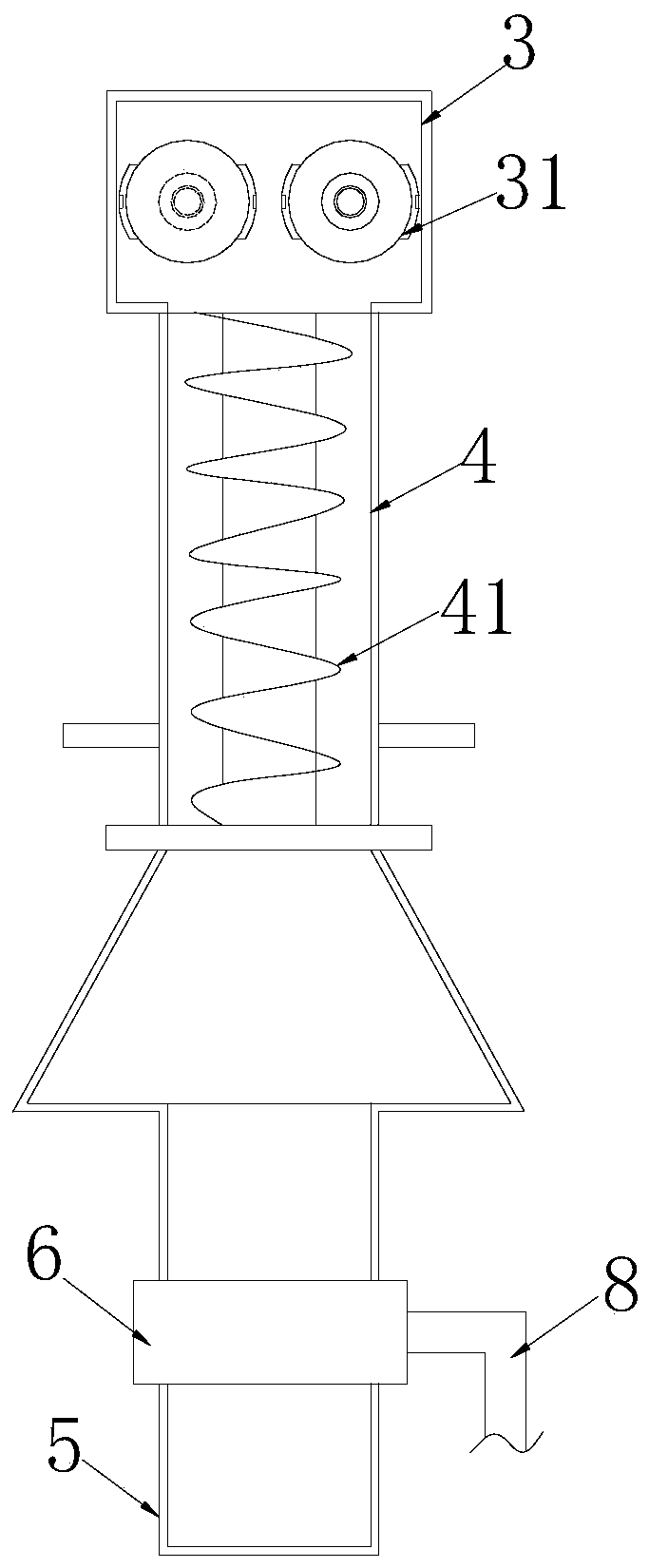

[0027] Such as figure 1 , figure 2 , Figure 4 , Figure 5 As shown, the present invention provides a kind of production equipment of polyester fiber reinforced strip, and its structure comprises cabinet 1, extrusion port 2, coating port 3, extrusion cavity 4, mixing cylinder 5, polyethylene adding port 6, deceleration 7, polyester fiber adding port 8, the chassis 1 controls the reducer 7, the signal output end of the reducer 7 is electrically connected to the extrusion chamber 5, and the inside of the extrusion chamber 5 is provided with an extrusion Screw 41, the extrusion chamber 5 is provided with a polyethylene addition port 6 and a polyester fiber addition port 8, the mixing cylinder 5 is horizontally connected to the inside of the extrusion chamber 4, and the extrusion chamber 4 is opposite to the mixing cylinder 5 Extrusion port 2 and coating port 3 are installed at one end of the tube, and strip roll 31 is arranged in the coating port 3. , the roller surface 311 ...

Embodiment 2

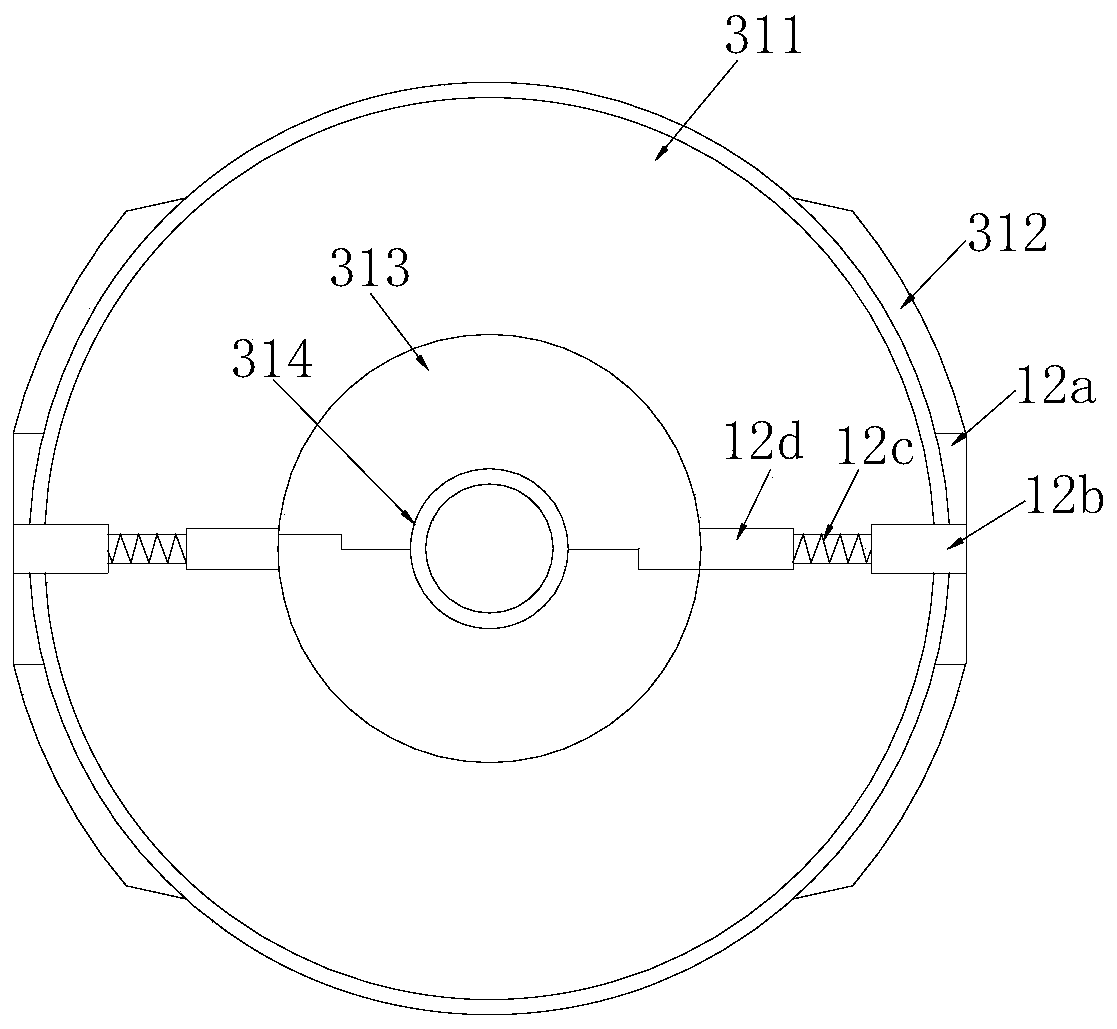

[0029] Based on the description in Example 1, as image 3 and Figure 6 As shown, the fitting disk 312 is an arc shape attached to the roller surface 311, and both sides are slope tangent structures. The gap between the roller surface 311 and the liquid outlet 12a is provided with a fine hole a, and the fine hole a There are more than two and are evenly distributed in the circumferential direction. The liquid collection tank 313 is divided into two equal parts, and each cut is in a Z shape. The roller surface 311 is a stepped double-layer structure. The contact between the layers is inclined to increase the oil outflow rate in the pores a, the sump 313 is divided into two equal parts, and the zigzag cut can well distribute the lubricant evenly to each outlet channel; At the same time, the roll surface 311 is double-layered, with inclined surfaces between the layers, so that the pores a have a more comprehensive liquid discharge, and the lubrication efficiency of the roll surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com