Efficient graphene roll-to-roll continuous growth equipment and preparation method

A graphene roll, graphene technology, applied in graphene, gaseous chemical plating, coating and other directions, can solve the problems of high power consumption, low production efficiency, etc., to improve production efficiency, good consistency, independent of size The effect of restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The disclosure also provides a method for preparing graphene: placing a plurality of metal substrates on a plurality of driven rollers in the feeding cabin, pulling the metal substrates into the receiving cabin and winding them on the driving roller; The cabin is evacuated, and then an inert gas is introduced from the air inlet at one end of the feed cabin; the heating device is turned on to heat the graphene growth area, so that the graphene growth area rises to the growth temperature of graphene; The air inlet is fed with carbon source gas; the motor is turned on to make the driving roller start to rotate and drive the metal substrate to run, and graphene is deposited on the metal substrate passing through the graphene growth zone. After the growth is completed, close the incoming reaction gas, heating device and motor, and after the temperature drops to room temperature, close the inert gas, open the breaker valve, and take out the metal substrate with graphene grown....

Embodiment 1

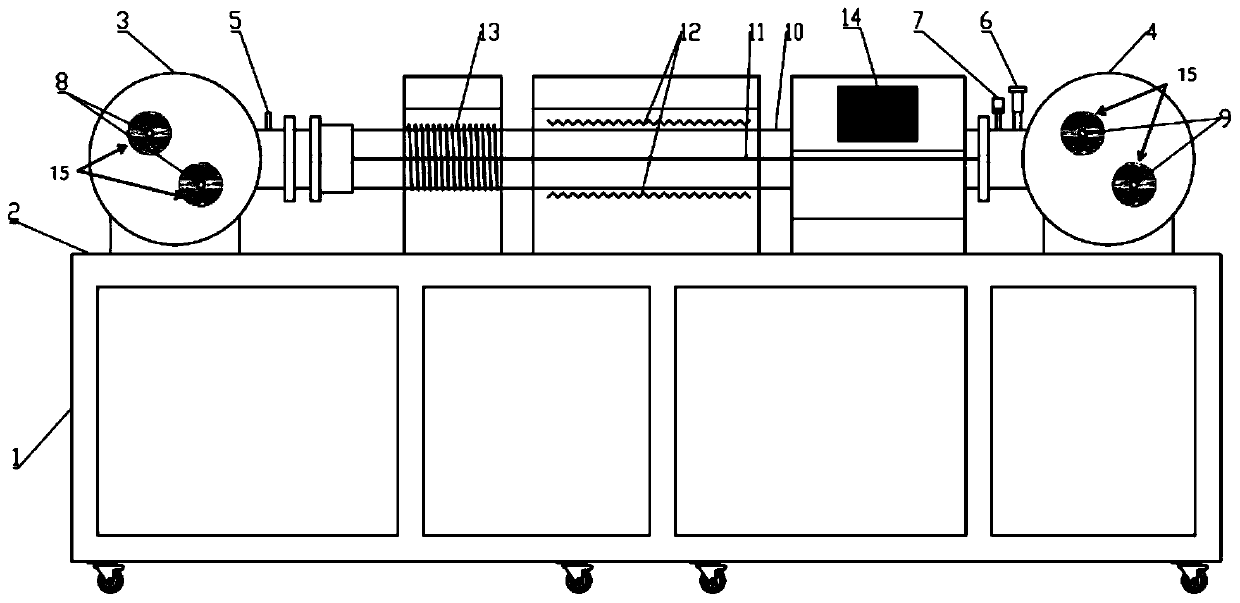

[0054] Such as figure 1 As shown, the high-efficiency graphene roll-to-roll continuous growth equipment of the present embodiment is a horizontal equipment, including a cabinet 1, and the cabinet 1 is provided with a workbench 2, and the two ends of the workbench 2 are respectively provided with a feed cabin 3 and a receiving chamber. Material cabin 4, feeding cabin 3 and material receiving cabin 4 are connected through quartz tube 10, feeding cabin 3 is equipped with two driven rollers 8, and material receiving cabin 4 is equipped with two driving rollers 9, two driving rollers 9 Connected to two motors respectively. There are air supply system, radio frequency power supply, control cabinet and vacuum unit in the cabinet 1, an air inlet 5 is provided at one end of the feeding cabin 3, and an air inlet 6 and a vacuum breaking valve 7 are arranged at one end of the receiving cabin 4, and the air outlet 6 is connected Vacuum unit. A plasma generator 13, a heating furnace 12 an...

Embodiment 2

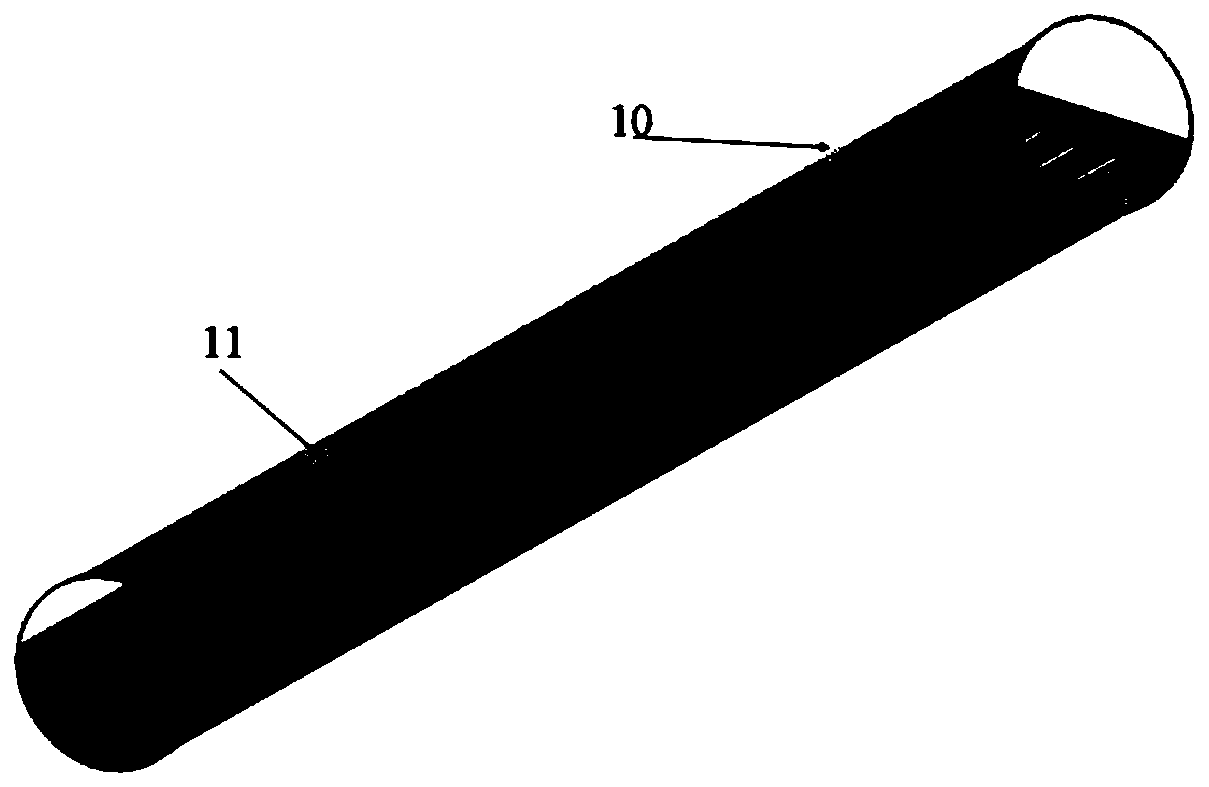

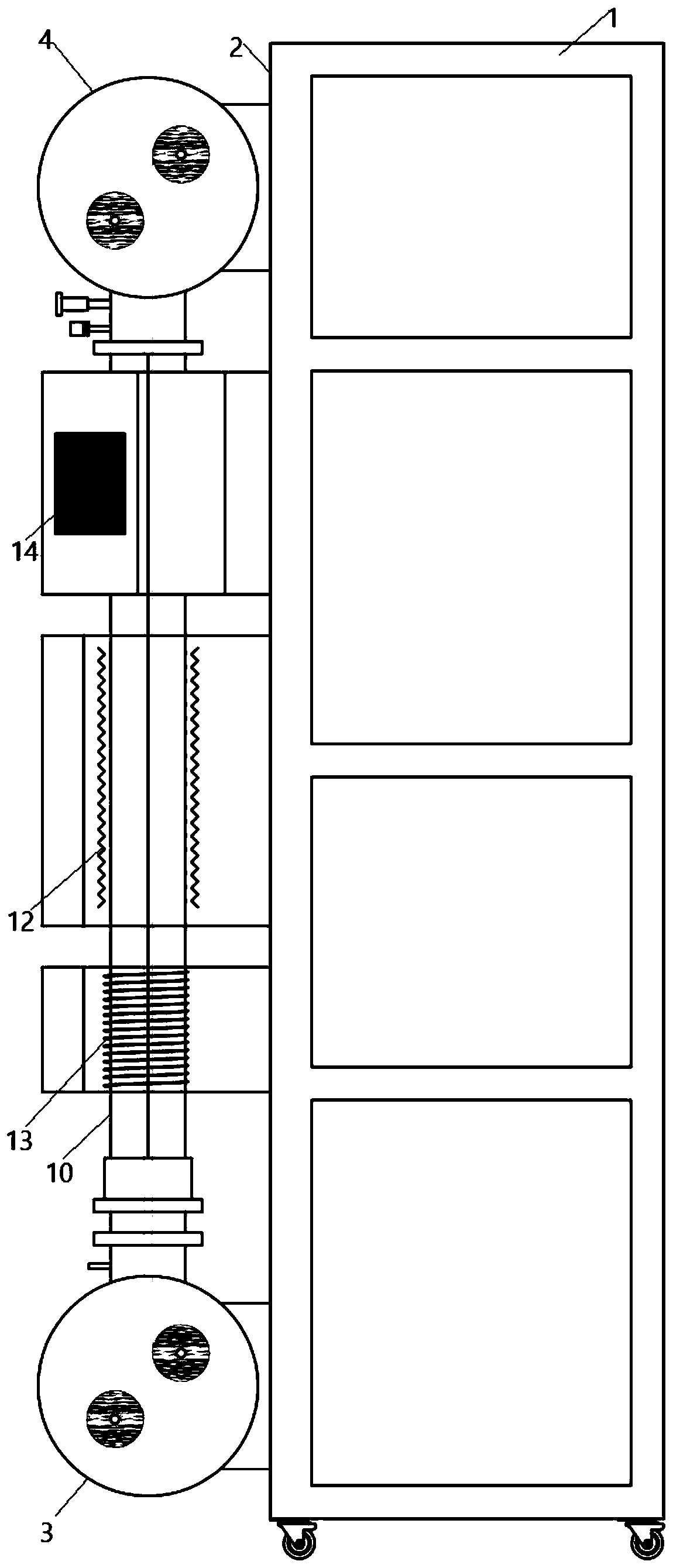

[0057] Such as image 3 As shown, the high-efficiency graphene roll-to-roll continuous growth equipment in this embodiment is a vertical equipment, including a cabinet 1 and a workbench 2. The main difference between the vertical equipment and the horizontal equipment in Embodiment 1 is that the installation methods of each component are different. , One side of the workbench 2 is sequentially installed with a feeding cabin 3, a quartz tube 10 and a receiving cabin 4 from bottom to top. A plasma generator 13 is arranged upstream of the quartz tube 10 , a heating furnace 12 is arranged midstream, and a blower fan (not shown in the figure) and a touch screen 14 are arranged downstream. Set inside the quartz tube 10 figure 2 In the quartz frame shown, the flat surface (isolation support plate 11) of the quartz frame is provided with an array of hollow holes.

[0058] The vertical growth equipment occupies a small area of the site, and the vertical growth equipment is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com