Sound insulation and shock absorption coating and preparation method thereof

A coating and pigment technology, applied in the field of sound insulation and shock absorption coating and its preparation, can solve the problems of high harmful volatile substances and heavy metals, poor noise prevention effect between floors, easy to cause harm to the human body, etc., and achieves high fire resistance and safe use. The effect of high performance, excellent shock absorption and buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

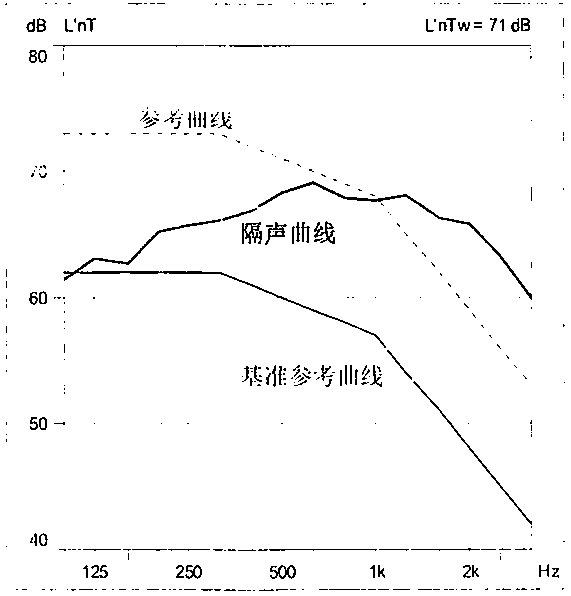

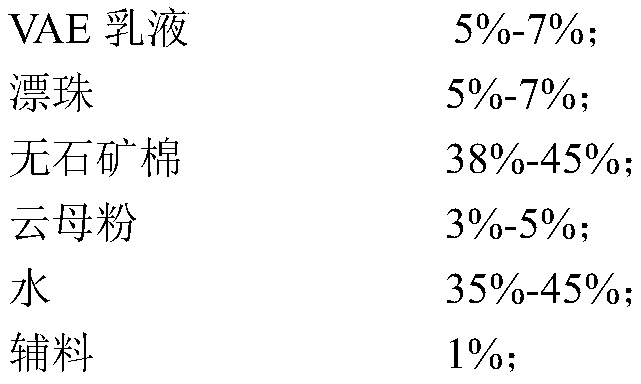

[0041] The sound-insulating and shock-absorbing coating of the present embodiment comprises the following components by weight percentage:

[0042]

[0043]

[0044] Wherein, the bulk density of the floating beads is 500kg / m 3 , the particle size is 100 mesh. Stone-free mineral wool refers to mineral wool with a heavy metal content of less than 5mg / kg, a fiber diameter of no more than 9μm, a slag ball content of no more than 10wt%, and a bulk density of 70kg / m 3 . The particle size of mica powder is 150 mesh.

[0045] The dry density of the sound-insulating and shock-absorbing coating of the present embodiment is 495kg / m 3 .

[0046] To prepare the described sound-insulating and shock-absorbing coating, the specific steps are as follows:

[0047] (1) Get 40 times the weight of the thickening agent in water, add the thickening agent, stir and disperse evenly at a rotating speed of 1500r / min, and set aside;

[0048] (2) Mix the VAE emulsion with the remaining water, ...

Embodiment 2

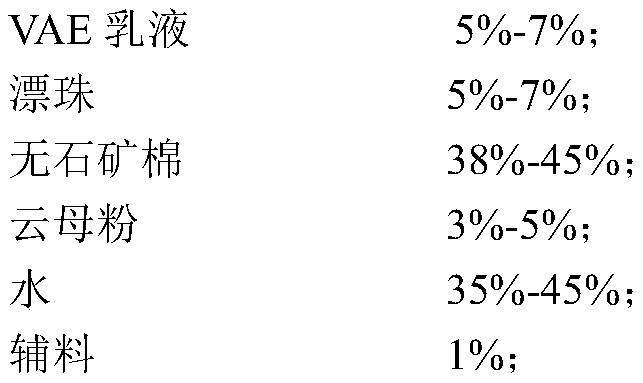

[0054] The sound-insulating and shock-absorbing coating of the present embodiment comprises the following components by weight percentage:

[0055]

[0056]Wherein, the bulk density of the floating beads is 550kg / m 3 , the particle size is 100 mesh. The stone-free mineral wool is mineral wool with a heavy metal content of less than 5 mg / kg, a fiber diameter of no more than 9 μm, a slag ball content of no more than 10 wt%, and a bulk density of 80 kg / m 3 . The particle size of the mica powder is 200 mesh.

[0057] The dry density of the sound-insulating and shock-absorbing coating of the present embodiment is 477kg / m 3 .

[0058] To prepare the described sound-insulating and shock-absorbing coating, the specific steps are as follows:

[0059] (1) Take water 50 times the weight of the thickener, add the thickener, stir and disperse evenly at a rotating speed of 1200r / min, and set aside;

[0060] (2) Mix the VAE emulsion with the remaining water, and stir and mix evenly ...

Embodiment 3

[0066] The sound-insulating and shock-absorbing coating of the present embodiment comprises the following components by weight percentage:

[0067]

[0068] Wherein, the bulk density of the floating beads is 450kg / m 3 , the particle size is 100 mesh. The stone-free mineral wool is purchased from Lingshou County Yazhi Mineral Products Processing Plant, which is mineral wool with a heavy metal content of less than 5 mg / kg, a fiber diameter of no more than 9 μm, a slag ball content of no more than 10 wt%, and a bulk density of 100 kg / m 3 . The particle size of the mica powder is 150 mesh.

[0069] The dry density of the sound-insulating and shock-absorbing coating of the present embodiment is 513kg / m 3 .

[0070] To prepare the described sound-insulating and shock-absorbing coating, the specific steps are as follows:

[0071] (1) Get the water of 45 times the weight of the thickener, add the thickener, stir and disperse evenly at 800r / min rotating speed, set aside;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com