Waterborne high-transparency polyurethane dye resin for synthetic leather and preparation method of waterborne high-transparency polyurethane dye resin

A dye resin and synthetic leather technology, which is applied in the field of synthetic leather water-based high-transparency polyurethane dye resin and its preparation, can solve the problems of uneven color of the upper and lower layers of the surface layer slurry, easy production accidents, and obvious color difference, etc., to achieve Excellent abnormal low temperature folding resistance, avoid color migration and floating, and be conducive to the effect of environmental protection transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

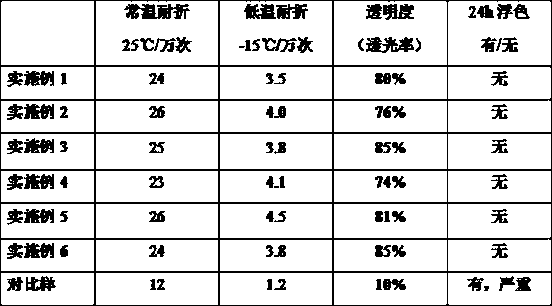

Examples

Embodiment 1

[0061] The raw materials used in this embodiment and their weight are shown in Table 1.

[0062] Table 1

[0063] raw material name Mass (unit: gram) Polycarbonate diol (number average molecular weight 2000) 120 Poly(hexanediol adipate) diol (number average molecular weight 2000) 60 Coloring polyol Red x64 (number average molecular weight 600) red 30 Dicyclohexylmethane diisocyanate 120 1,6-diisocyanate 20 DMPA 18 Hexylene glycol 15 Catalyst BICAT ® 8 0.2 acetone 270 Triethylamine 13.56 Ethylenediamine 4.2 water 750

[0064] The preparation steps of the synthetic leather water-based high transparency polyurethane dye resin of the present embodiment are as follows:

[0065] 1) Put 120g of polycarbonate diol, 60g of polyhexamethylene adipate diol, and 30g of colored polyol into the reaction kettle, and stir at 50°C for 20 minutes until the mixture is uniform;

[0066]2) Put 120g of dicyclohex...

Embodiment 2

[0069] The raw materials used in this embodiment and their weight are shown in Table 2.

[0070] Table 2

[0071] raw material name Mass (unit: gram) Polycarbonate diol (number average molecular weight 2000) 120 Polytetrahydrofuran diol (number average molecular weight 2000) 60 Colored polyol (number average molecular weight 560) blue 30 Isophorone diisocyanate 100 1,6-diisocyanate 20 DMPA 18 Hexylene glycol 15 Catalyst BICAT® 8 0.2 acetone 270 Triethylamine 13.56 Ethylenediamine 5.0 water 710

[0072] The preparation steps of the synthetic leather water-based high transparency polyurethane dye resin of the present embodiment are as follows:

[0073] 1) Put 120g of polycarbonate diol, 60g of polytetrahydrofuran diol, and 30g of colored polyol into the reaction kettle, and stir at 50°C for 20 minutes until the mixture is uniform;

[0074] 2) Put 100g of isophorone diisocyanate and 20g of 1,6...

Embodiment 3

[0077] The raw materials used in this embodiment and their weight are shown in Table 3.

[0078] table 3

[0079] raw material name Mass (unit: gram) Polycarbonate diol (number average molecular weight 2000) 120 Polycaprolactone diol (number average molecular weight 2000) 60 Colored polyol (number average molecular weight 500) yellow 30 Antioxidant 1010 2 Dicyclohexylmethane diisocyanate 100 1,6-diisocyanate 20 DMPA 10 Hexylene glycol 15 Catalyst BICAT® 3184 0.2 Triethylamine 7.54 Sodium ethylenediaminoethanesulfonate 50% aqueous solution (A-95) 10 acetone 340 Ethylenediamine 5.11 water 695

[0080] The preparation steps of the synthetic leather water-based high transparency polyurethane dye resin of the present embodiment are as follows:

[0081] 1) Put 120g of polycarbonate diol, 60g of polyhexamethylene adipate diol, 30g of colored polyol, and 2g of antioxidant 1010 into the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com