A kind of bimetallic catalyst, its preparation method and application in preparing polyether polyol

A bimetallic catalyst, polyether polyol technology, applied in the field of polyether polyol, can solve the problems affecting production efficiency and product quality, polyether polyol is easy to appear foggy, small particle size, etc., and achieves easy operation and production. The effect of high efficiency and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

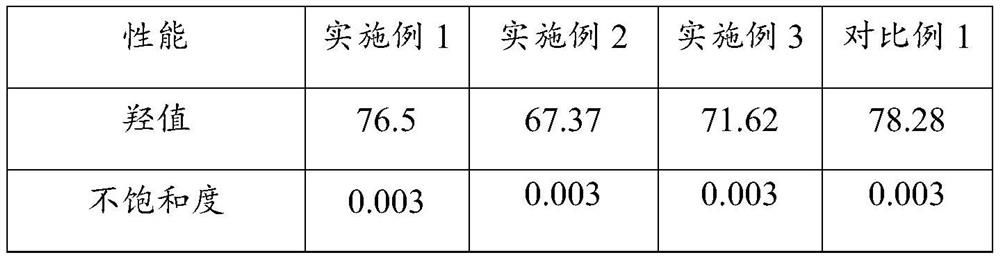

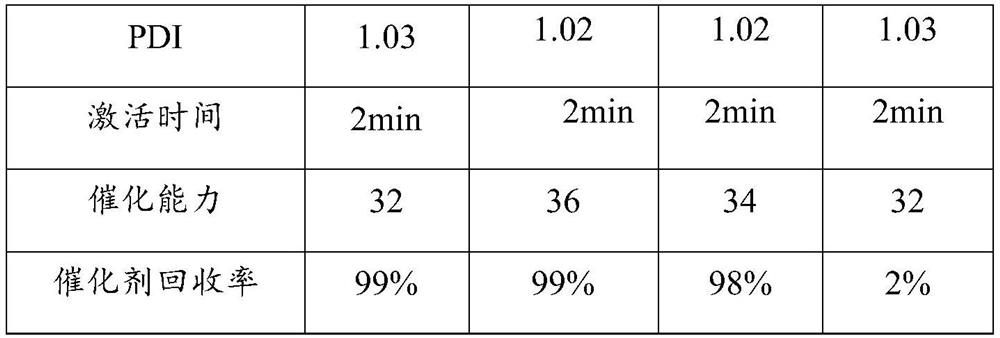

Examples

Embodiment 1

[0035] 1. Synthesis of bimetallic catalysts:

[0036] 1) 10g of polylactic acid-polyoxypropylene glycerol ether block polymer (molecular weight: 4000g / mol, purchased from Hangzhou Xinqiao Biotechnology Co., Ltd.) was dissolved in methylene chloride (10ml), and 50g of zinc chloride aqueous solution was dissolved in (Concentration: 40%) was slowly added dropwise thereto, and the temperature was raised to 40°C to prepare a catalyst precursor.

[0037] 2) Add 50g of tert-butanol to 70g of potassium hexacyanocobaltate aqueous solution with a concentration of 60%, and after stirring, slowly dropwise the catalyst precursor described in step 1) in the above solution, maintain a temperature of 40° C., and react. After 2 h, a solution of the crude catalyst was obtained.

[0038] 3) 50g polyethylene glycol aqueous solution (molecular weight is 600g / mol, concentration is 30%) is added dropwise to the bimetallic catalyst crude product solution obtained in step 2) at 40° C., stirred for 12...

Embodiment 2

[0044] 1. Synthesis of bimetallic catalysts:

[0045]1) 10g of polylactic acid-polyoxypropylene glycerol ether block polymer (molecular weight: 6000g / mol, purchased from Hangzhou Xinqiao Biotechnology Co., Ltd.) was dissolved in methylene chloride (10ml), and 50g of zinc chloride aqueous solution was dissolved in (Concentration: 40%) was slowly added dropwise thereto, and the temperature was raised to 40°C to prepare a catalyst precursor.

[0046] 2) Add 50g of tert-butanol to 70g of potassium hexacyanocobaltate aqueous solution with a concentration of 60%, and after stirring, slowly dropwise the catalyst precursor described in step 1) in the above solution, maintain a temperature of 40° C., and react. After 2 h, a solution of the crude catalyst was obtained.

[0047] 3) 50g polyethylene glycol aqueous solution (molecular weight is 600g / mol, concentration is 30%) is added dropwise to the bimetallic catalyst crude product solution obtained in step 2) at 40° C., stirred for 12h...

Embodiment 3

[0053] 1. Synthesis of bimetallic catalysts:

[0054] 1) 10g polylactic acid-polyoxypropylene glycerol ether block polymer (molecular weight: 5000g / mol, purchased from Hangzhou Xinqiao Biotechnology Co., Ltd.) was dissolved in dichloromethane (10ml), and 50g zinc chloride aqueous solution was dissolved (Concentration: 40%) was slowly added dropwise thereto, and the temperature was raised to 40°C to prepare a catalyst precursor.

[0055] 2) Add 50g of tert-butanol to 70g of potassium hexacyanocobaltate aqueous solution with a concentration of 60%, and after stirring, slowly dropwise the catalyst precursor described in step 1) in the above solution, maintain a temperature of 40° C., and react. After 2 h, a solution of the crude catalyst was obtained.

[0056] 3) 50g polyethylene glycol aqueous solution (molecular weight is 600g / mol, concentration is 30%) is added dropwise to the bimetallic catalyst crude product solution obtained in step 2) at 40° C., stirred for 12h under the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com