Energy-saving and environment-friendly heat-dissipating device

A heat-dissipating device, energy-saving and environment-friendly technology, applied in preheating, steam superheating, feed water heaters, etc., can solve the problems of heat loss, unstable power generation, waste of resources, etc., and achieve the effect of improving efficiency, reducing heat loss and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

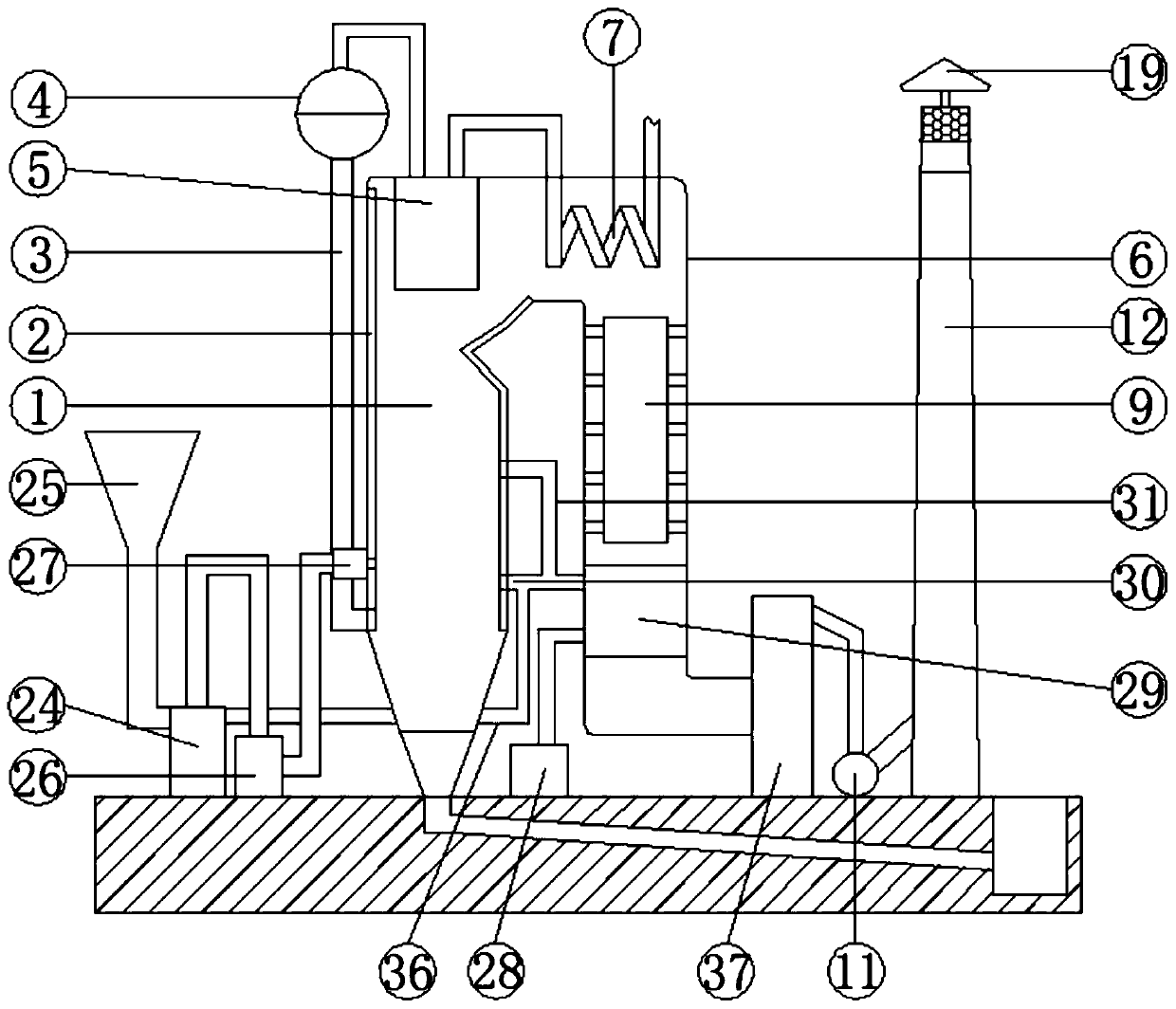

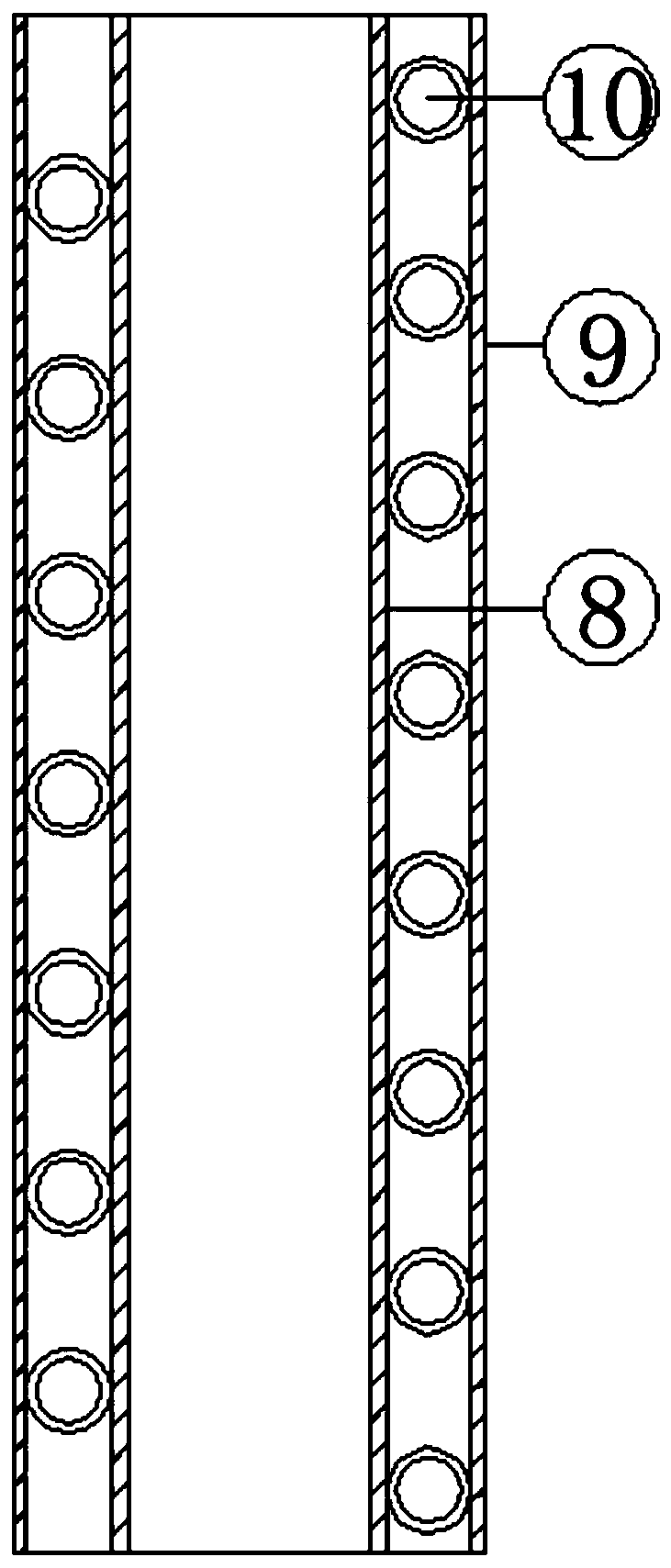

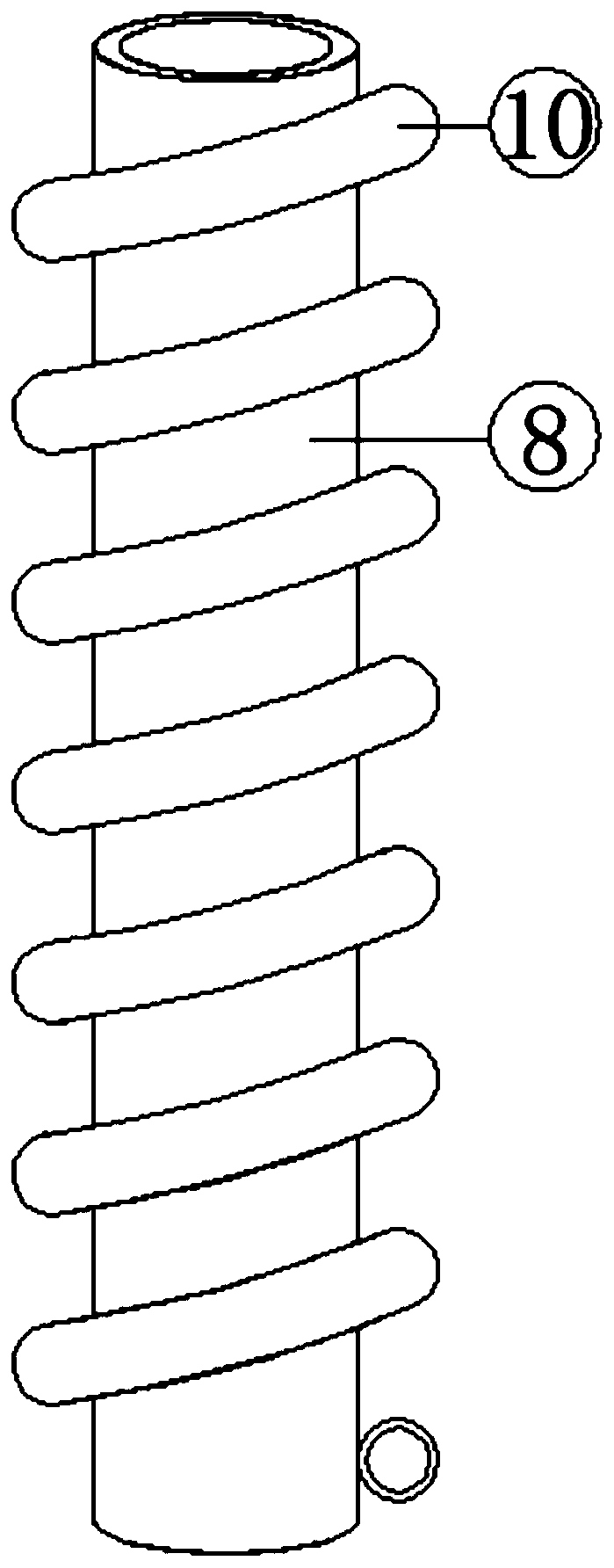

[0041] see Figure 1-8 , according to an embodiment of the present invention, an energy-saving and environment-friendly heat dissipation device includes a furnace body 1, a feeding device is provided on one side of the furnace body 1, a water-cooled wall 2 is fixed on the inner wall of the furnace body 1, and a water-cooled wall 2 is fixed on the inner wall of the furnace body 1. The outer wall of one side is fixed with a downcomer 3, the upper end of the downcomer 3 is fixed with a steam drum 4, the inner wall of the upper end of the furnace body 1 is fixed with a primary superheater 5, and the upper end of the furnace body 1 is fixed with a row A smoke pipe 6, the smoke exhaust pipe 6 has a Z-shaped structure, the inner wall of the upper end of the smoke exhaust pipe 6 is fixed with a secondary superheater 7, and the middle part of the smoke exhaust pipe 6 is provided with a preheating device, and the preheating device Including an inner cylinder 8, the outer wall of the inn...

Embodiment 2

[0045] see figure 1 , for the feeding device, the feeding device includes a coal mill 24, a feeder 25, a pulverizer 26 and a burner 27, and the input end of the coal mill 24 is fixedly provided with a feeder 25, so The output end of the coal mill 24 is connected with the input end of the pulverizer 26 through a conduit, and the output end of the pulverizer 26 is connected with the input end of the burner 27 through a conduit, and the burner 27 is fixedly embedded in the side wall of the furnace body 1 and the output end of the burner 27 protrudes into the furnace body 1 .

[0046] Through the above scheme of the present invention, the coal fed by the feeder 25 can be pulverized by the coal mill 24, and then injected into the body of furnace 1 through the pulverizer 26 and the burner 27 for combustion, so that the coal can be Burn more fully.

Embodiment 3

[0048] see figure 1 , 5 and 6, for the air supply device, the air supply device includes a blower 28, an air preheating device 29, a primary air supply pipe 30 and a secondary air supply pipe 31, and the output end of the described air supply blower 28 is connected with the described The input end of the air preheating device 29 is connected, and the air preheating device 29 is installed on the inner wall of the lower end of the exhaust pipe 6, and the output end of the air preheating device 29 is connected with a primary air supply pipe 30 and a secondary air supply pipe. Pipe 31, the end of the primary air supply pipe 30 away from the air preheating device 29 is connected to the middle of the furnace body 1, and the end of the secondary air supply pipe 31 away from the air preheating device 29 is connected to the furnace body 1 connection at the upper end; for the air preheating device, the air preheating device 29 includes a second cylinder 32, and one side of the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com