Skid-mounted medical waste incinerator

A technology for medical waste and incinerators, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of not getting the expected treatment effect, breeding a large number of bacteria and viruses, and high construction costs of incinerators, so as to ensure harmless treatment. Handling, compact structure, the effect of reducing equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

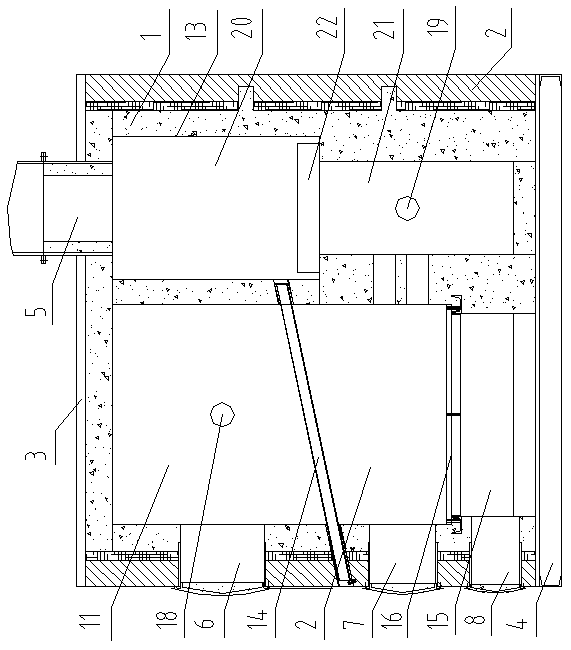

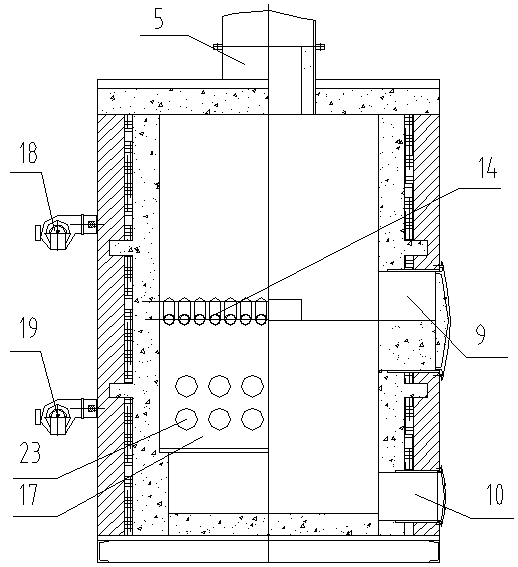

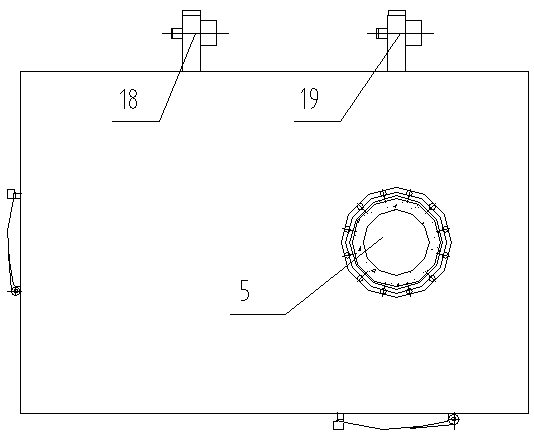

[0021] A skid-mounted medical waste incinerator, including a cube or cuboid furnace body, the structure of the furnace body is surrounded by an adiabatic furnace wall (1) and a U-shaped cavity is formed inside, the furnace body adopts a skid-mounted structure, The heat insulation layer (2) is wrapped around the furnace body, the top surface of the furnace body is provided with a protective plate (3), the bottom surface of which is fixed on the steel frame (4), and the upper surface of the furnace body is provided with a flue outlet (5) , the two sides of the furnace body are respectively provided with solid medical waste feeding port (6), secondary combustion chamber inspection hole (7), ash bin ash digging hole (8), liquid or thick state medical waste feeding port (9) And dig out ash hole (10) in reburning chamber. The incinerator adopts a three-stage combustion method according to the characteristics of medical waste, so there are three combustion chambers arranged in the U-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com