Spontaneous combustion type domestic waste cracking furnace

A domestic waste and pyrolysis furnace technology, which is applied in the field of self-igniting domestic waste pyrolysis furnace, can solve the problems of large environmental pollution and unstable cracking temperature, and achieve the effect of high-efficiency neutralization treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

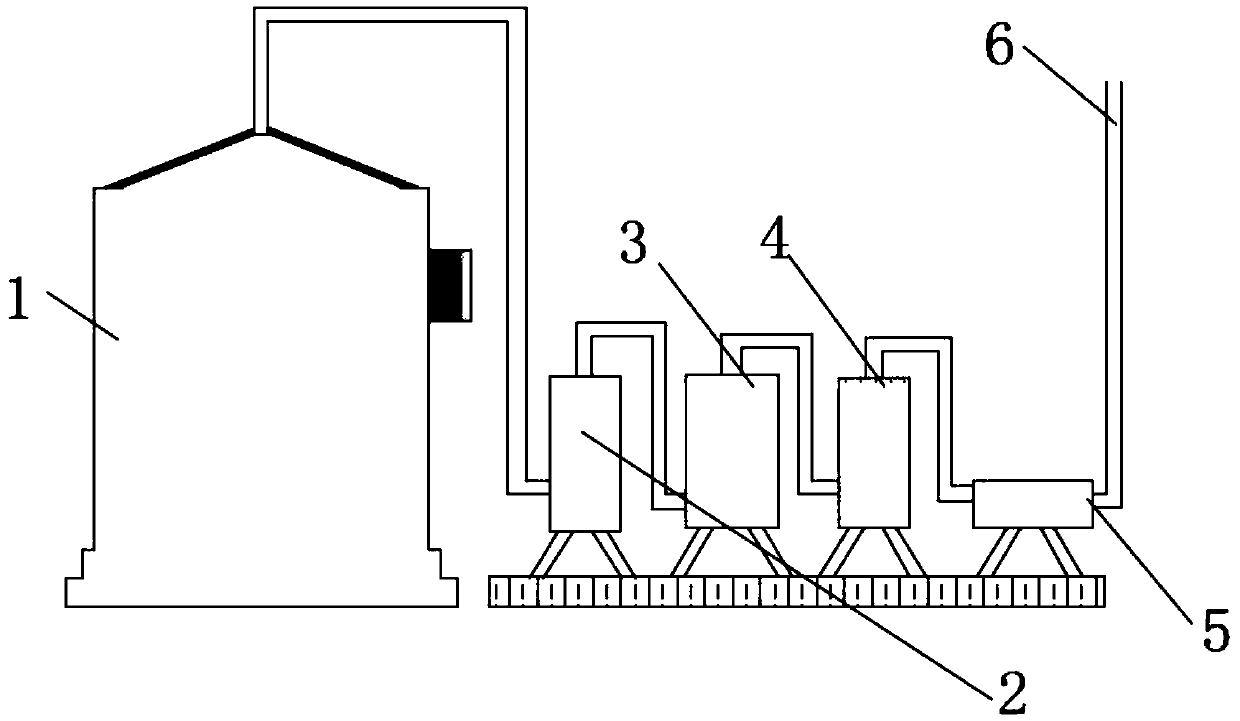

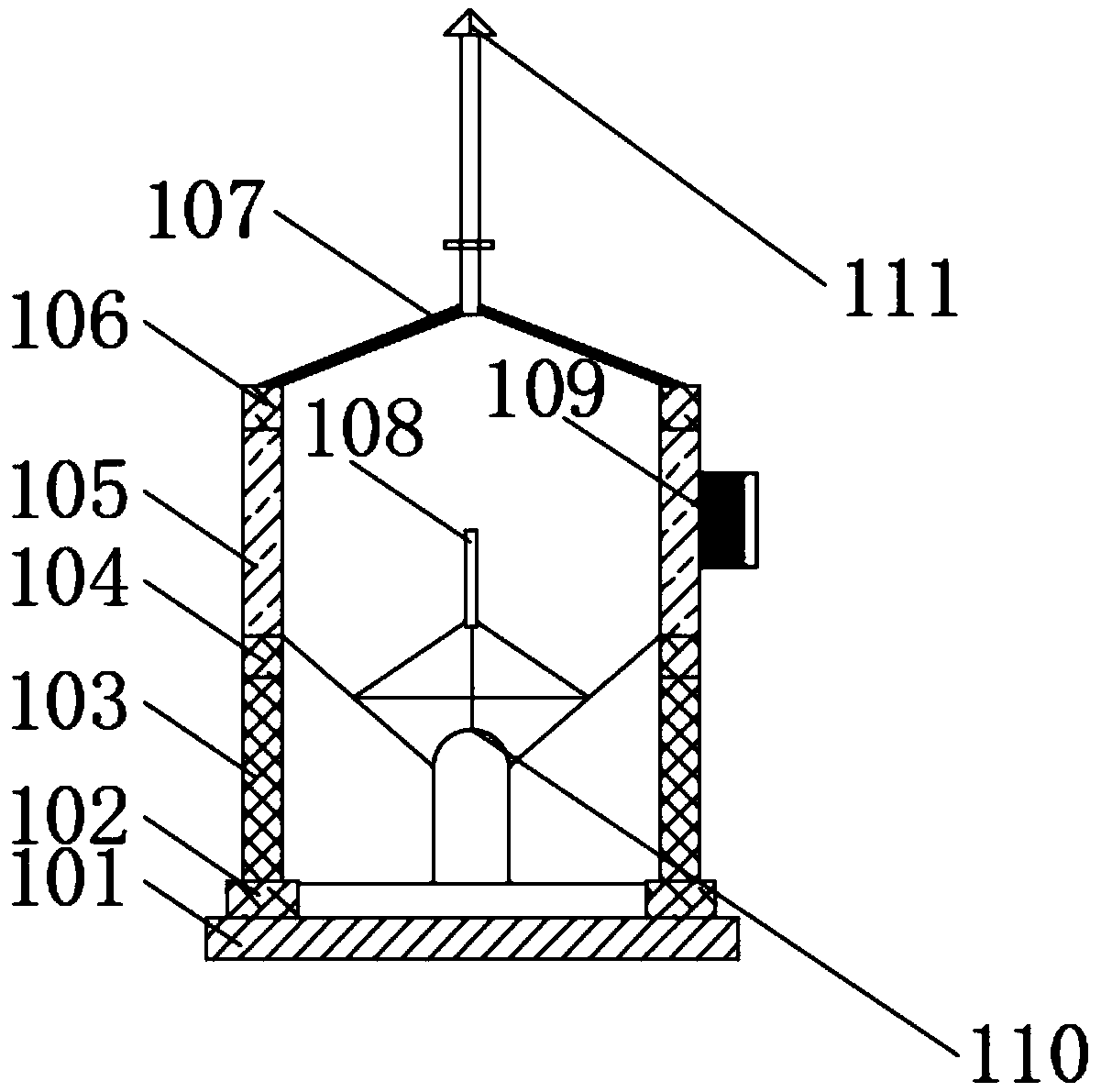

[0035] Such as figure 1 , 2 As shown, the embodiment of the present invention provides a kind of self-igniting domestic waste pyrolysis furnace, which includes a pyrolysis furnace main body 1, and is characterized in that: one side of the pyrolysis furnace main body 1 is provided with a high-pressure spray system 2, and the high-pressure spray system 2 is far away from the pyrolysis furnace One side of the main body 1 is provided with a high-pressure desulfurization neutralizer 3, and the side of the high-pressure desulfurization neutralizer 3 away from the cracking furnace main body 1 is provided with a liquid-gas separation system 4, and the liquid-gas separation system 4 is provided with a side away from the cracking furnace main body 1. There is a fine filtration system 5, a cracking furnace main body 1, a high-pressure spray system 2, a high-pressure desulfurization neutralizer 3, a liquid-gas separation system 4 and a fine filtration system 5 are sequentially embedded wi...

Embodiment 2

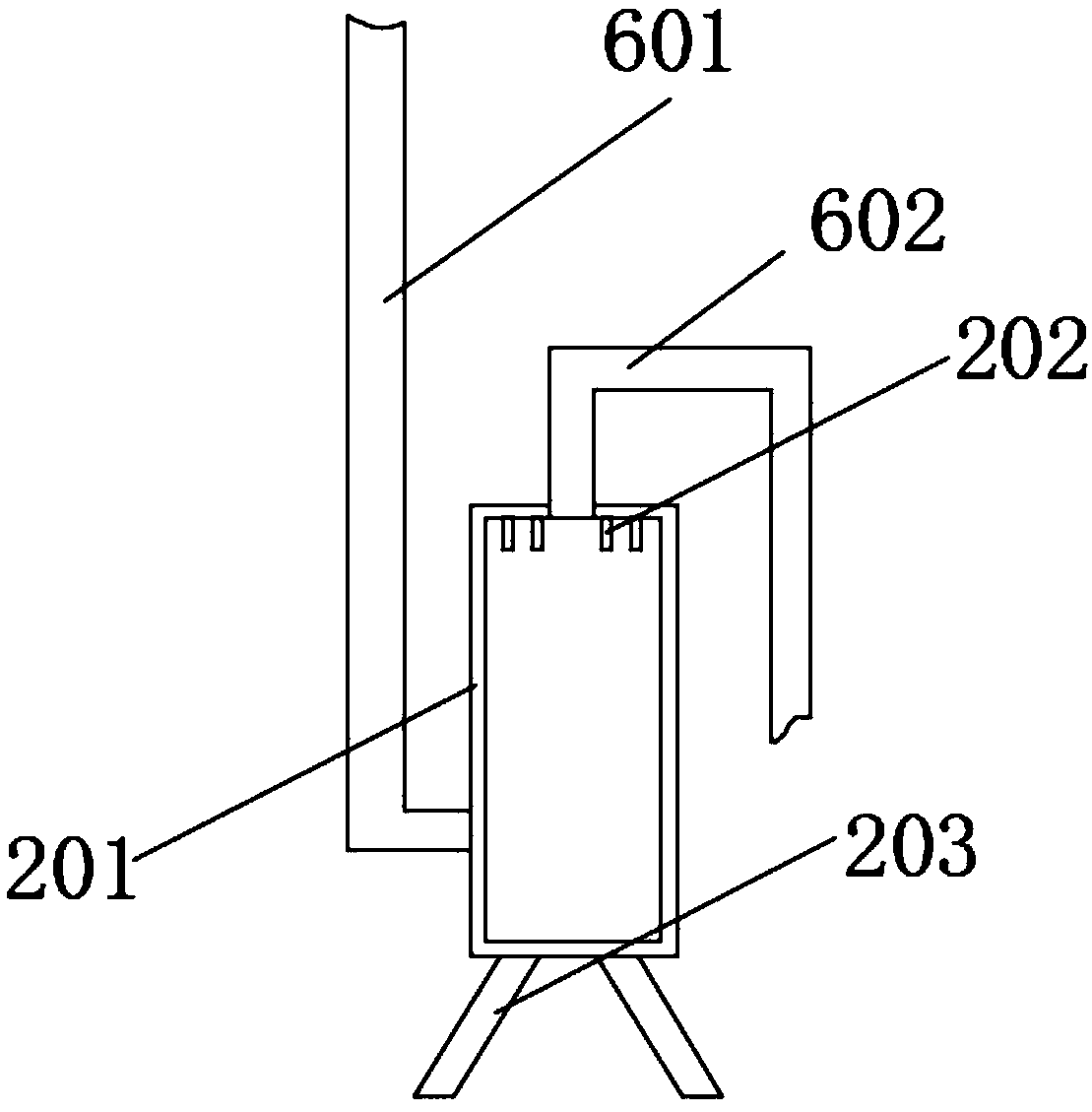

[0037] Such as image 3 , 4As shown in , 5, the embodiment of the present invention provides a kind of self-combustion domestic garbage pyrolysis furnace, the high-pressure spray system 2 includes a high-pressure shell 201, a main spray head 202 and a mounting bracket 203, and the maximum bearing pressure of the high-pressure shell 201 is not less than two MPa, the number of main shower heads 202 is two groups, two in each group, evenly installed on both sides of the top surface of the inner cavity of the high-pressure shell 201, the liquid-gas separation system 4 includes a working shell 401 and a conical separation disc 402, the cone The conical separation disc 402 is arranged in the middle of the inner cavity of the working shell 401, and the surface of the conical separation disc 402 is provided with a clockwise protrusion, and the surface of the conical separation disc 402 is provided with a one-way permeable membrane for water. The fine filtration system 5 Including the...

Embodiment 3

[0039] Such as Figure 1-5 As shown, the embodiment of the present invention provides a kind of self-combustion domestic waste cracking furnace, the water circulation system 6 includes a flue gas discharge pipe 604, the end of the flue gas discharge pipe 604 is provided with an auxiliary smoke pipe cap 605, the pyrolysis furnace main body 1 and the high-pressure jet A flue gas input pipe 601 is provided between the shower system 2, a pretreatment output pipe 602 is provided between the high-pressure spray system 2 and the high-pressure desulfurization neutralizer 3, and a pretreatment output pipe 602 is provided between the liquid-gas separation system 4 and the high-pressure desulfurization neutralizer 3. There is an intermediate transition pipe 603, the main body of the pyrolysis furnace 1, the high-pressure spray system 2, the high-pressure desulfurization neutralizer 3, the liquid-gas separation system 4 and the fine filtration system 5 are arranged in a sequential manner, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com