Simulation method of cyclic motion of power and free trolley of suspension type production line

A technology of cyclic motion and simulation method, which is applied in the direction of instruments, simulators, control/regulation systems, etc., can solve the problems of reducing the cost of production line transformation, shortening the cycle of production line transformation, and the cyclic motion of the accumulating car does not match the actual situation, etc., to achieve Avoid the effect of building and modifying at the same time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

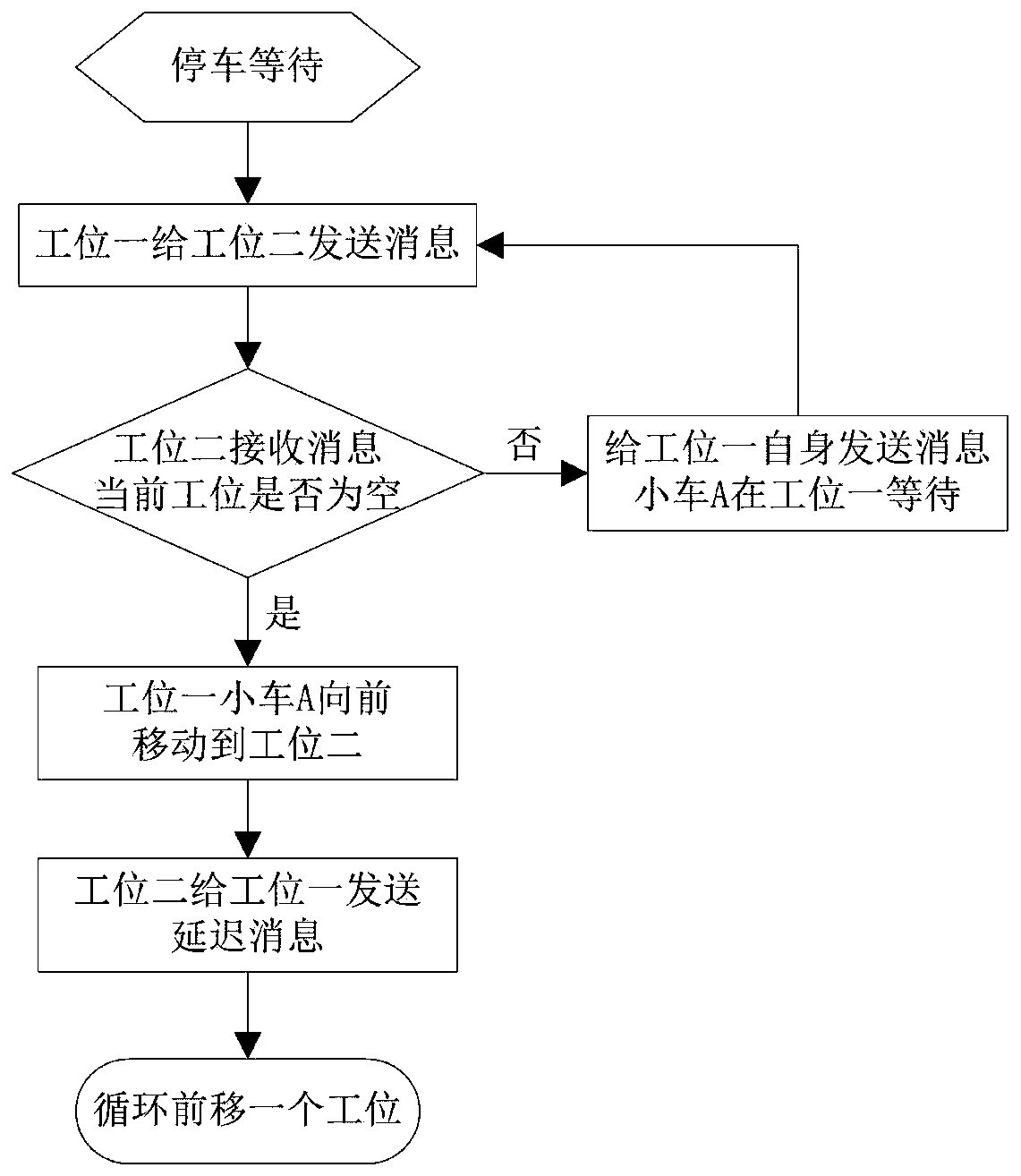

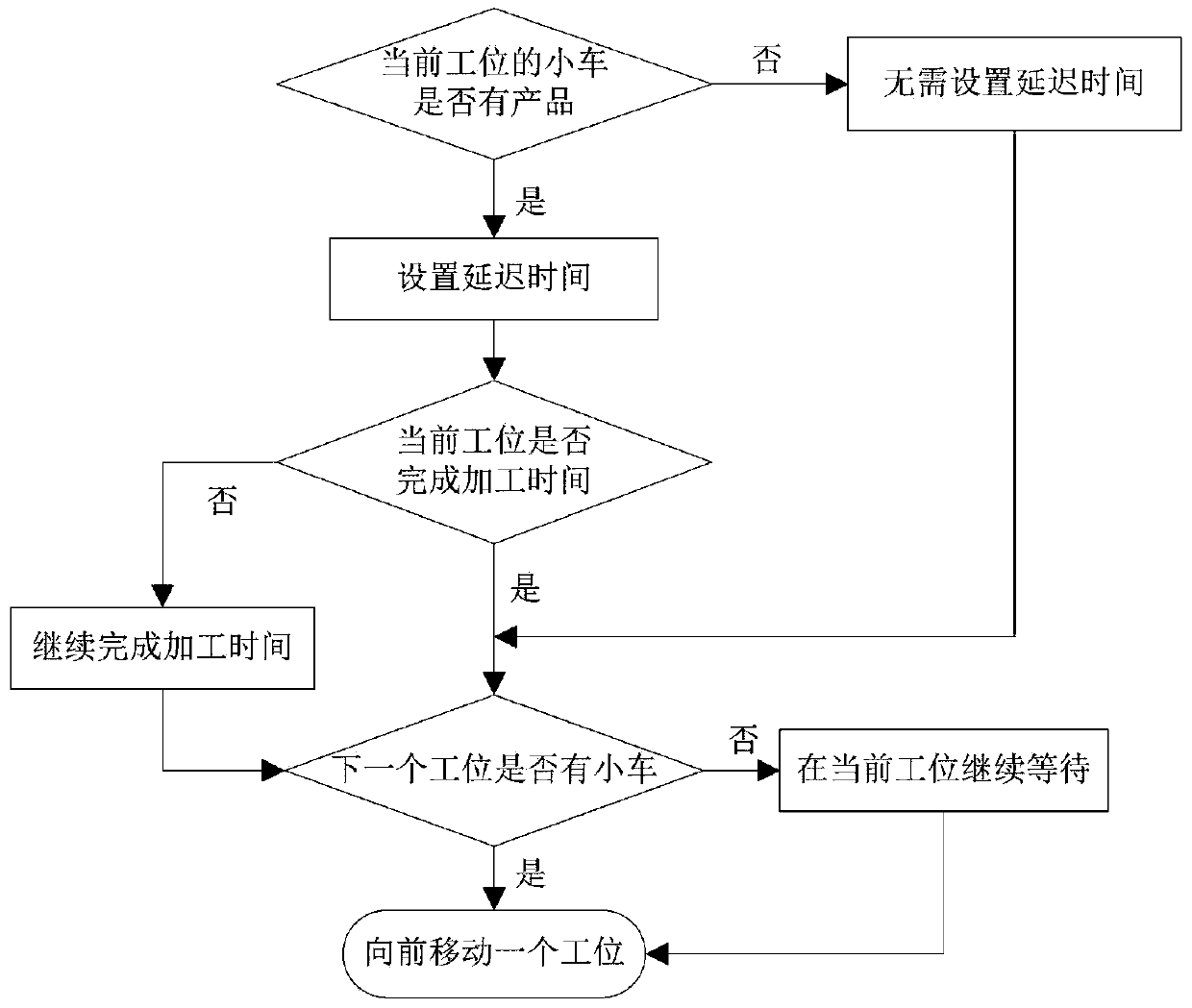

[0031] A method for simulating the cyclic motion of a suspended production line accumulating trolley according to the present invention, specifically comprises the following steps:

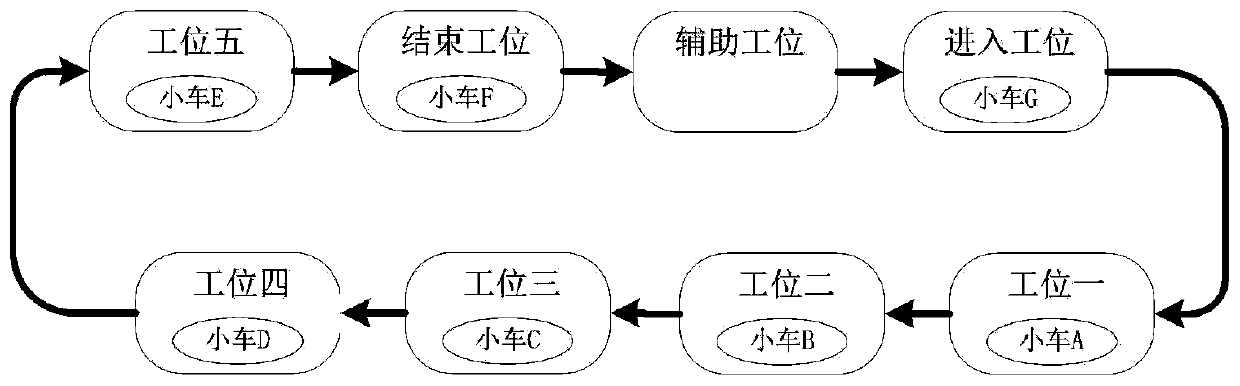

[0032] Design the structure and operation mode of the accumulating trolley in the production line: there is a suspension chain in the air, and the accumulating trolley is suspended by the suspension chain. When the trolley is at a certain station, the processing of the corresponding process is carried out.

[0033] According to the characteristics of the suspended production line, that is, according to the structure and operation mode of the suspended production line, the simulation model is established in the discrete system simulation software: first, the suspension chain is laid and the production line station is set, and the movement mode of the suspension chain accumulating trolley is set; Secondly, the status of each station is recorded in the system in real time (the state of processing or n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com