Preparation method of personalized customization type craniomaxillofacial bone surgery repair and reconstruction implant

A craniofacial and orthopedic surgery technology, applied in bone implants, joint implants, joint implants, etc., can solve the problems of difficult to repair structural defects, the strength of titanium mesh cannot meet the requirements, etc., to improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

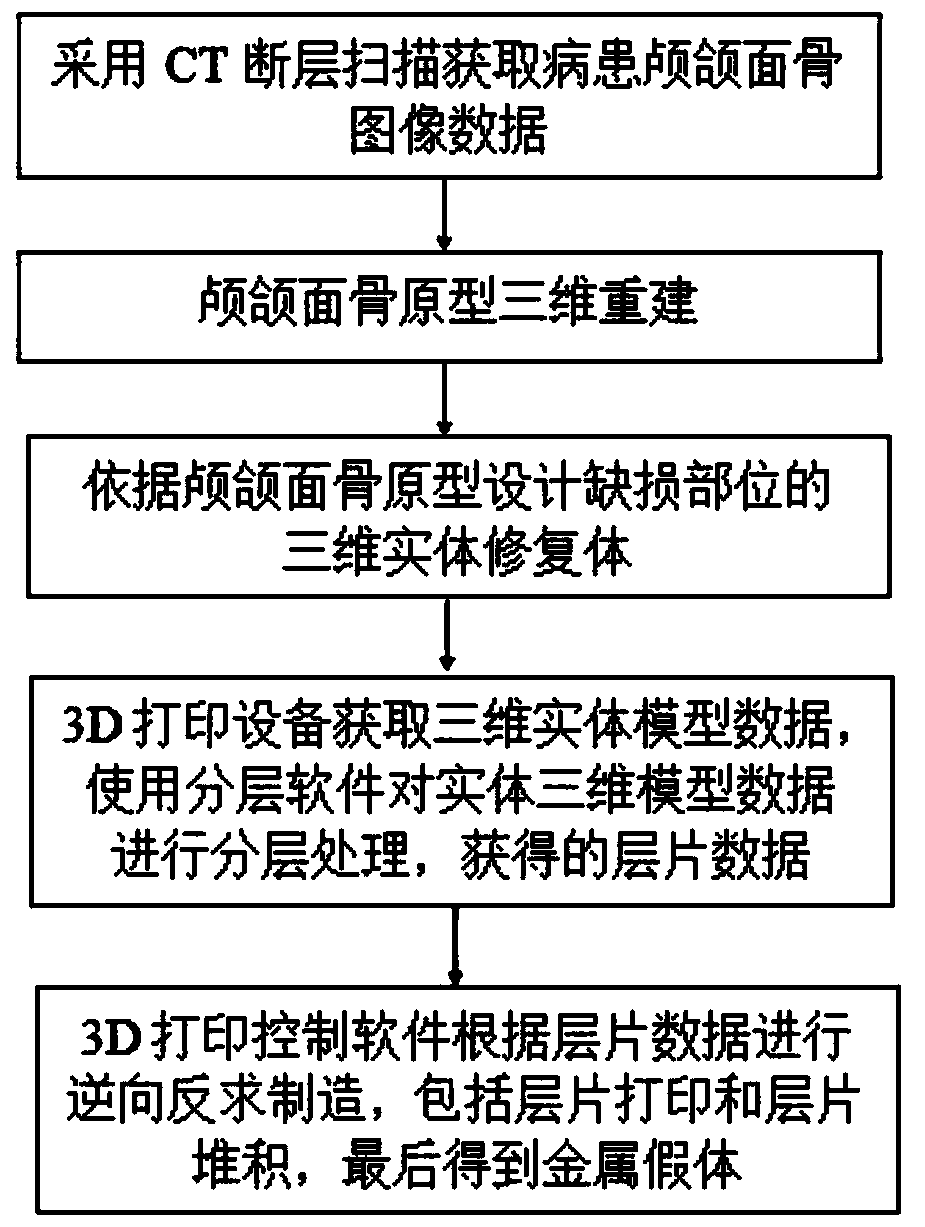

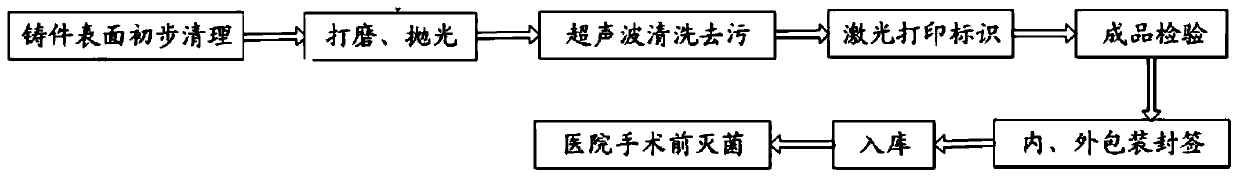

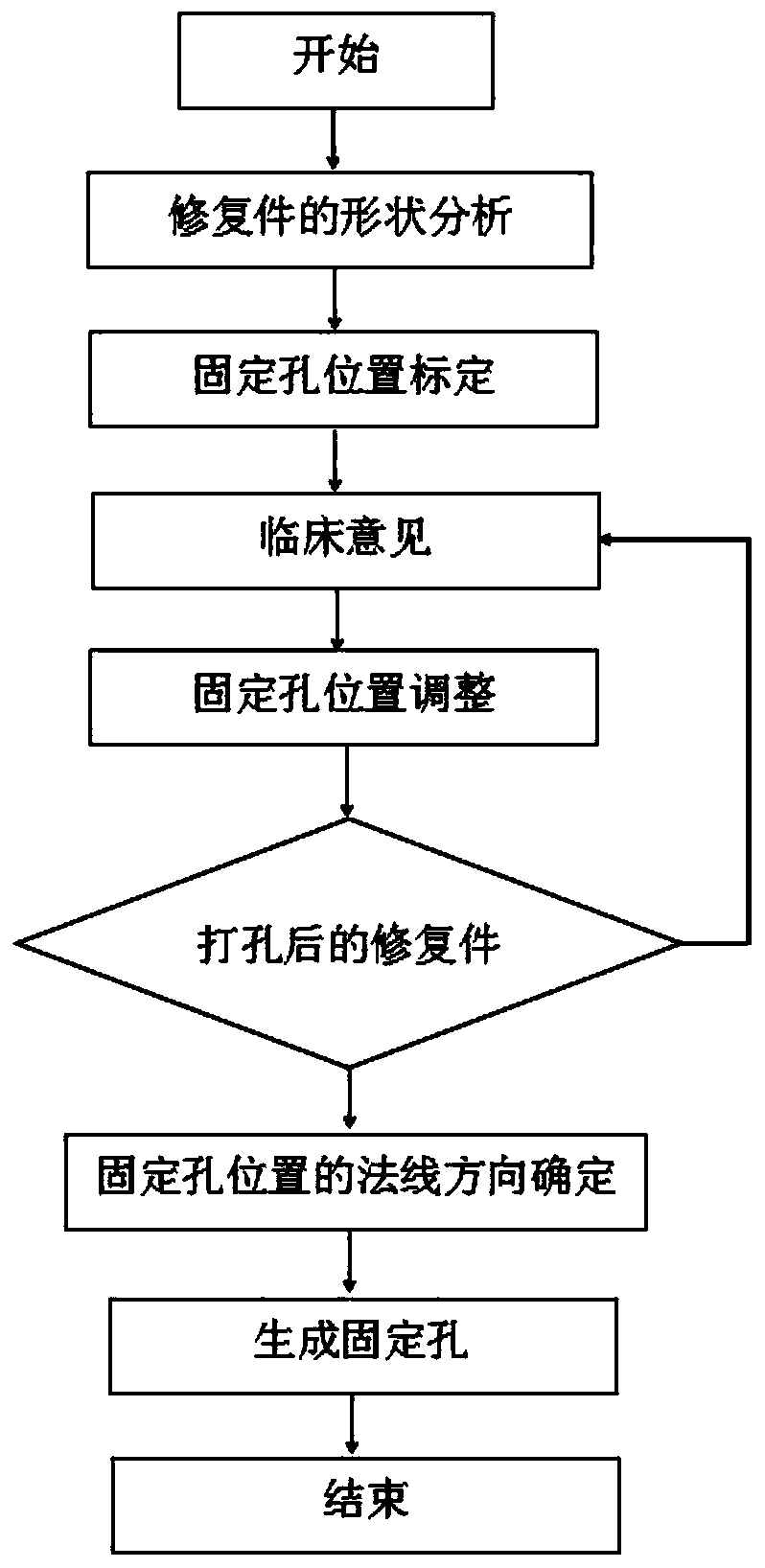

[0029] refer to figure 1 , 2 , 3, and 4, the present invention specifically discloses a method for preparing a personalized and customized craniofacial surgical repair and reconstruction implant, comprising the following steps:

[0030] Step 1: Obtain the three-dimensional data of the cranio-maxillofacial bone prototype: use X-ray film or CT scan to obtain the image data of the patient's cranio-maxillofacial bone, record the data into a CD-ROM file in standard DICOM format, and store it in the general medical image control system software A computer reads craniomaxillofacial bone image data from the storage medium;

[0031] Step 2: 3D reconstruction of the cranio-maxillofacial bone prototype, processing the tomographic image data of the cranio-maxillofacial bone in the CT image, including filtering, roughness reduction-grayscale image binarization-contour extraction-vectorized 3D modeling, using STL format to output the 3D model data of the craniofacial bone prototype;

[0...

Embodiment 1

[0042] Embodiment 1 (the design of the mandibular substitute of right half side defect Figure 5 )

[0043] Include the following steps:

[0044] Step 1: Obtain the three-dimensional data of the mandible prototype: use X-ray film or CT scan to obtain the tomographic image data of the patient's mandible, record the data in a standard DICOM format as a CD-ROM file, and store it in the computer of the general medical image control system software. The storage medium reads in the tomographic image data of the mandible;

[0045] Step 2: 3D reconstruction of the mandible prototype, preprocessing the tomographic image data of the mandible in the CT image, including image filtering, image smoothing and image denoising; binarizing the preprocessed grayscale image, the purpose of which is to Image segmentation is mainly the segmentation of bone tissue and soft tissue; after the above processing, the single-valued area of the target contour can be obtained, and the outer contour value ...

Embodiment 2

[0056] Embodiment 2 (the typical structure of the mandibular substitute of left hemi defect Figure 6 )

[0057] Include the following steps:

[0058] Step 1: Obtain the three-dimensional data of the mandible prototype: use X-ray film or CT scan to obtain the tomographic image data of the patient's mandible, record the data in a standard DICOM format as a CD-ROM file, and store it in the computer of the general medical image control system software. The storage medium reads in the tomographic image data of the mandible;

[0059] Step 2: 3D reconstruction of the mandible prototype, preprocessing the tomographic image data of the mandible in the CT image, including image filtering, image smoothing and image denoising; binarizing the preprocessed grayscale image, the purpose of which is to Image segmentation is mainly the segmentation of bone tissue and soft tissue; after the above processing, the single-valued area of the target contour can be obtained, and the outer contour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com