Flat niti alloy electron beam welding anisotropic cooling device and its welding method

A technology of electron beam welding, heat dissipation and cooling, used in electron beam welding equipment, welding/welding/cutting items, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

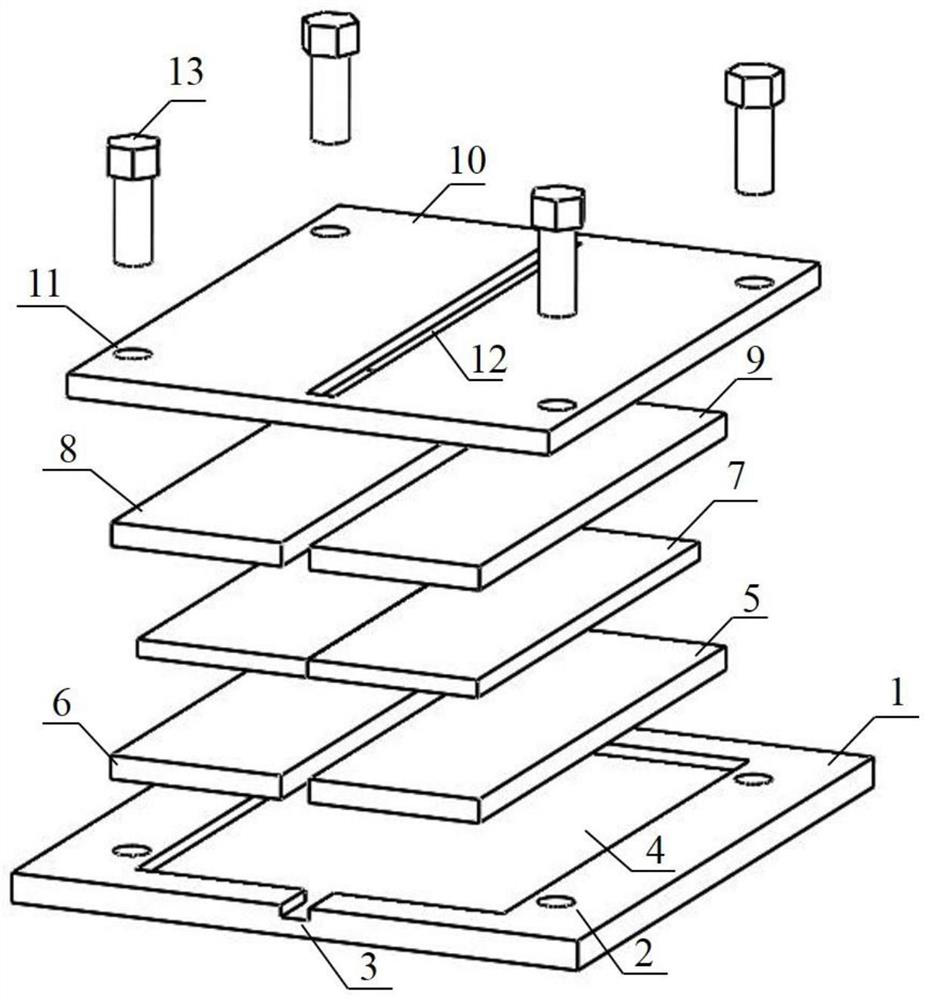

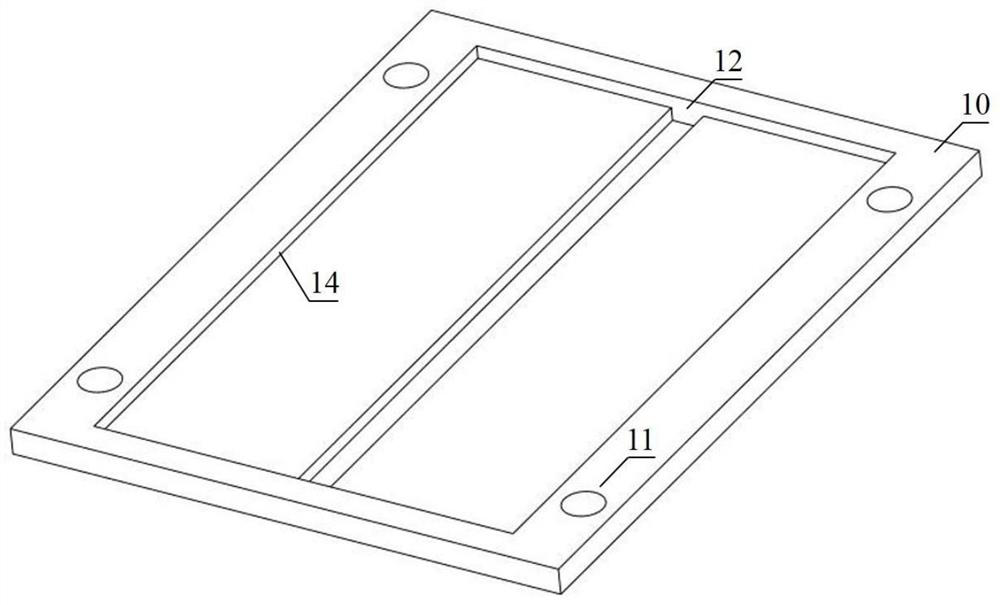

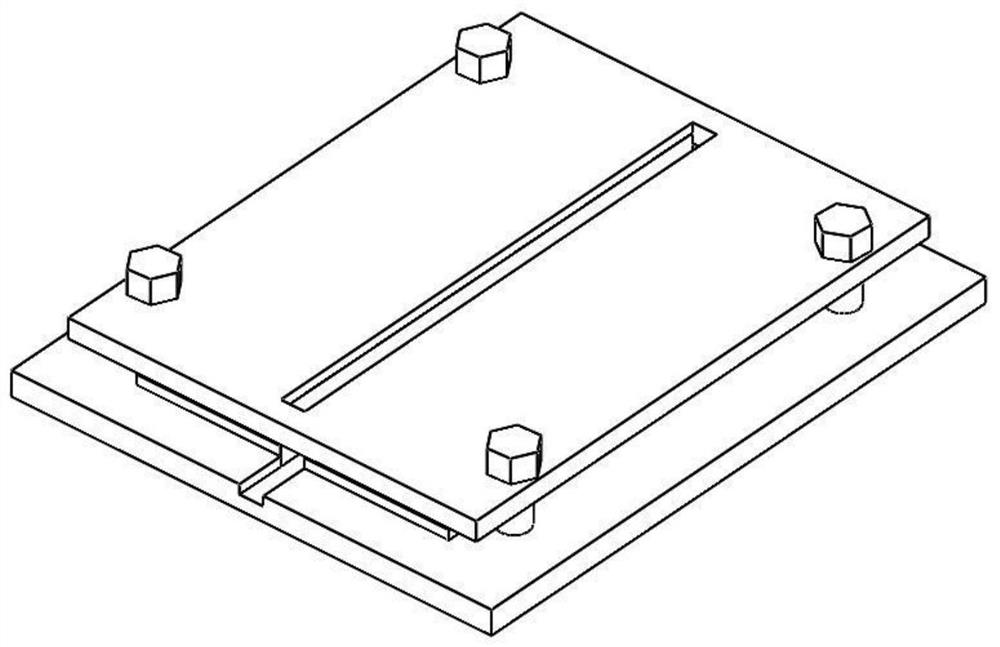

[0027] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment. This embodiment is a flat NiTi alloy electron beam welding anisotropic heat dissipation cooling device. Its composition includes a fixture bottom plate 1, a lower cooling copper plate 5, a lower thermal insulating ceramic plate 6, an upper cooling copper plate 8, and an upper thermal insulating ceramic plate. 9 and the fixture cover plate 10, the middle part of the upper end surface of the fixture bottom plate 1 is provided with a bottom plate groove 4, and the lower heat insulating ceramic plate 6 and the lower layer cooling copper plate 5 are arranged side by side in the bottom plate groove 4 along the width direction, and the fixture cover plate 10 is arranged on Directly above the fixture bottom plate 1, a cover plate groove 14 is arranged in the middle of the lower end surface of the fixture cover plate 10. In the cover plate groove 14, an upper layer cooling red copper plate 8...

specific Embodiment approach 2

[0038] Specific implementation mode two: combination figure 1 This embodiment is described. In this embodiment, a groove 3 is respectively provided in the middle of the front and rear ends of the bottom plate groove 4 on the fixture bottom plate 1 . The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0039]The groove 3 can prevent the electron beam from penetrating the sample and acting on the fixture, so as to protect the bottom plate 1 of the fixture.

specific Embodiment approach 3

[0040] Specific implementation mode three: combination figure 1 This embodiment is described. In this embodiment, gaps are provided between the lower thermal insulation ceramic plate 6 and the lower cooling copper plate 5 and between the upper cooling copper plate 8 and the upper thermal insulation ceramic plate 9 . The undisclosed technical features in this embodiment are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com