Sewage treatment system with good use effect

A sewage treatment system and sewage treatment technology, applied in the field of environmental protection, can solve the problems of reduced activity of beneficial bacteria, reduction of air pollution around equipment, etc., to achieve the effect of improving efficiency and effect, improving dehumidification effect, and ensuring smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

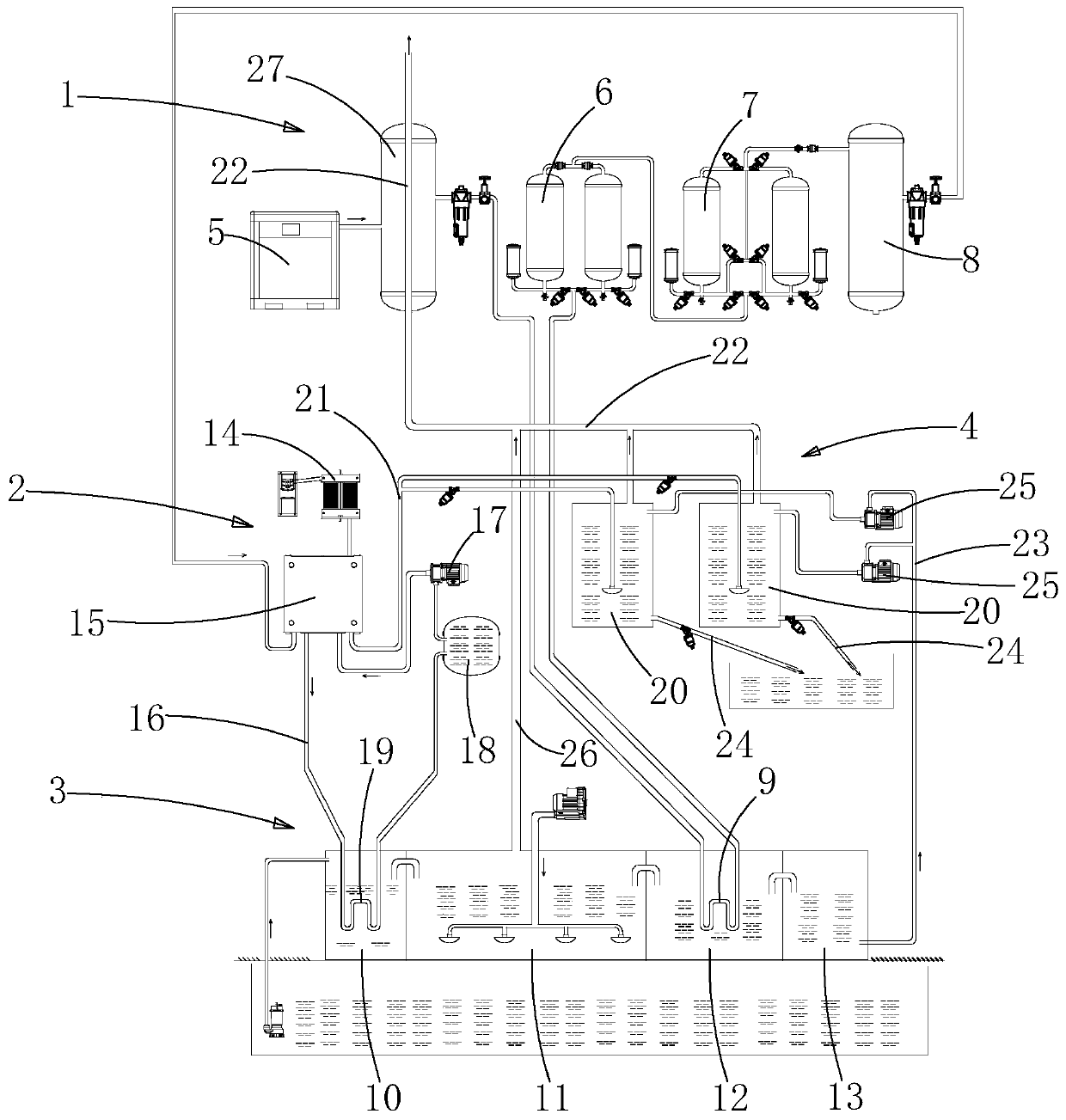

[0017] The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] like figure 1 A sewage treatment system with good use effect shown is composed of an oxygen production unit 1, an ozone production unit 2, a sewage treatment unit 3, and a sewage disinfection unit 4. The ozone production unit 2 receives oxygen from the oxygen production unit 1 and processes it to form Ozone is used for sterilization, and the sewage degraded by the sewage treatment part 3 is mixed with ozone for sterilization treatment. The oxygen production part 1 includes an air compressor 5, an air drying component 6, an oxygen production component 7 and an oxygen storage tank connected in series through pipelines in sequence. 8. The pipeline is located between the air buffer tank 27 and the air drying assembly 6. There is a first heat dissipation area 9, and the first heat dissipation area 9 is immersed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com