Graphite porous crucible and preparation method thereof

A graphite crucible technology, applied in the field of graphite porous crucible and its preparation, can solve the problems of low flexural strength, high resistivity, and low crucible compactness, and achieve improved compactness, low resistivity, and high compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

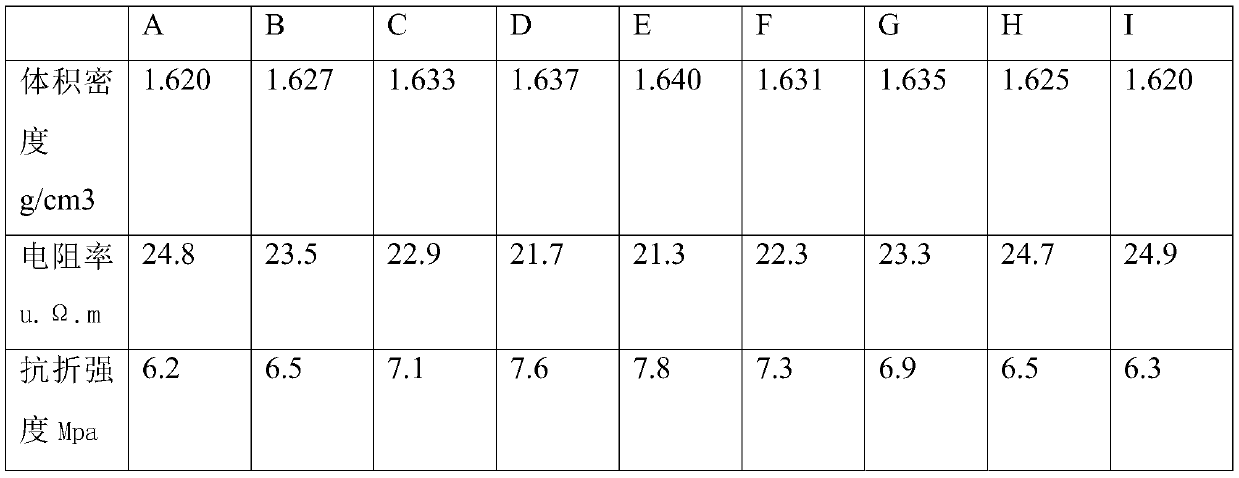

Examples

Embodiment 1

[0029] Select 52 parts of graphitized calcined coke, 48 parts of graphitized thermal insulation material, and 20 parts of modified pitch. Mechanically crush and grind graphitized calcined coke and graphitized thermal insulation material to obtain graphitized calcined coke with a particle size of 0-8mm. Coke, graphitized thermal insulation material with a particle size of 0-2mm, kneaded with a 3000L medium-sized kneader, preheated the kneading pot to 140°C, and added graphitized calcined coke and graphitized thermal insulation material into the kneading pot under normal pressure. Heat to 115°C, dry mix for 30 minutes, discharge the moisture in the material, add the modified asphalt into the kneading pot, and discharge the obtained paste into the hopper after wet mixing for 45 minutes; put the paste in the hopper into the preheated and preheated In the air-drying mixing drum with a heating temperature of 80°C, stir and air-dry the material for 10 minutes, and use the horizontal v...

Embodiment 2

[0031] Select 52 parts of graphitized calcined coke, 48 parts of graphitized thermal insulation material, and 20 parts of modified pitch. Mechanically crush and grind graphitized calcined coke and graphitized thermal insulation material to obtain graphitized calcined coke with a particle size of 0-8mm. Coke, graphitized thermal insulation material with a particle size of 0-2mm, kneaded with a 3000L medium-sized kneader, preheated the kneading pot to 140°C, and added graphitized calcined coke and graphitized thermal insulation material into the kneading pot under normal pressure. Heat to 117°C, dry mix for 30 minutes, discharge the moisture in the material, add the modified asphalt into the kneading pot, and discharge the obtained paste into the hopper after wet mixing for 45 minutes; put the paste in the hopper into the preheated and preheated In the air-drying mixing drum with a heating temperature of 80°C, stir and air-dry the material for 12 minutes, and use the horizontal v...

Embodiment 3

[0033] Select 52 parts of graphitized calcined coke, 48 parts of graphitized thermal insulation material, and 20 parts of modified pitch. Mechanically crush and grind graphitized calcined coke and graphitized thermal insulation material to obtain graphitized calcined coke with a particle size of 0-8mm. Coke, graphitized thermal insulation material with a particle size of 0-2mm, kneaded with a 3000L medium-sized kneader, preheated the kneading pot to 140°C, and added graphitized calcined coke and graphitized thermal insulation material into the kneading pot under normal pressure. Heat to 120°C, dry mix for 30 minutes, drain the moisture in the material, add the modified asphalt into the kneading pot, and discharge the obtained paste into the hopper after wet mixing for 45 minutes; put the paste in the hopper into the preheated and preheated In the air-drying mixing drum with a heating temperature of 80°C, stir and air-dry the material for 15 minutes, and use a horizontal vibrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com