A kind of low temperature composite material threaded column composition

A technology of composite materials and threaded columns, which is applied in the direction of threaded fasteners, screws, bolts, etc., can solve the problems of high mechanical strength of low temperature resistance, poor low temperature resistance, large thermal conductivity, etc., to improve thermal insulation function and reduce thermal conductivity , the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

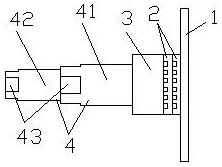

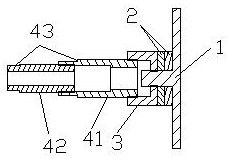

[0034] This embodiment is a preferred structure, such as Figure 1-5 As shown, a low-temperature composite threaded column consists of threaded column and gasket 2, both of which are made of fiber-reinforced composite material with low temperature resistance and good heat insulation performance, threaded column and gasket 2 They are all hollow structures, and the threaded column is provided with an internal thread near the hollow inner side of the gasket 2, and the entire threaded column composition is fixed on the fixing plate 1 through the internal thread.

[0035] Such as Figure 4 and Figure 5 As shown, one annular surface of the gasket 2 is provided with grooves 21 of equidistant tooth structure, and the grooves 21 are filled with aerogel with high thermal insulation performance, and the number, depth and width of the grooves 21 depend on the application environment performance requirement settings. With fiber-reinforced composite material as the skeleton, the gasket ...

Embodiment 2

[0041] Such as Figure 4 and Figure 6 As shown, in this embodiment, the gasket 2 is a groove 21 with equidistant tooth structures arranged on the annular surfaces on both sides, and the groove 21 is filled with airgel. Figure 6The grooves 21 on both sides are arranged in the same way, and the grooves 21 on both sides of the gasket 2 can also be arranged perpendicular to each other. At this time, the thickness of the gasket 2 can be set to be greater than the thickness of the gasket 2 in the first embodiment according to the needs, and only one gasket 2 can be used in one threaded column. Of course, the actual size and quantity of the gasket 2 can be Adjust according to the usage environment.

Embodiment 3

[0043] Such as Figure 7 and Figure 8 As shown, in this embodiment, a groove 21 is provided on one side of the gasket 2, and the groove 21 is filled with airgel, wherein the arrangement of the groove 21 is: the extension line of the centerline of all the grooves 21 All pass through the center of the circle, and all the grooves 21 are arranged symmetrically, which not only ensures the strength of the gasket 2, but also facilitates processing and assembly. When in use, two layers of gaskets 2 can be superimposed, and the positions of the grooves 21 of the two layers of gaskets 2 are stacked at the same position to ensure the strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com