A low-temperature composite material threaded column composition molding method

A composite material and molding method technology, applied in the field of threaded post forming and composite threaded post forming, can solve the problems of high low temperature resistance mechanical strength, poor low temperature resistance, low thermal conductivity, etc., to improve the thermal insulation function, comprehensive Excellent performance and the effect of reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

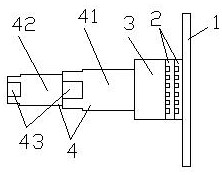

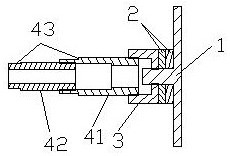

[0041] In this example, the raw material for preparing the threaded column is 360tex glass fiber yarn, and the molding method is: 360tex glass fiber yarn impregnated with low-temperature resin is wound on the threaded mold of the upper threaded column, the tension is 80-100N, and the width of the yarn sheet is the length of the thread pitch , the resin content is 25%-27%, the winding speed is 0.1-0.2m / s, winding to the required thickness, continue to rotate until gel, and send it to the curing oven for curing. The curing temperature is 90°C for 2h+110°C for 2h. After demoulding, use a diamond tool to process the external threads to obtain the upper threaded column 42, the middle threaded column 41 and the seat body 3. The process method is the same as above.

[0042] Such as Figure 4 and Figure 6 As shown, the gasket 2 is designed as a groove 21 with equidistant tooth structure on the ring surface on both sides, and the structure filled with airgel in the groove 21, Figur...

Embodiment 2

[0044] In this example, the raw material for preparing the threaded column is 960tex glass fiber yarn, and the forming method is: 960 tex glass fiber yarn impregnated with low-temperature resin is wound on the threaded mold of the upper threaded column, the tension is 80-100N, and the width of the yarn piece is the thread pitch Length, resin content 30%-32%, winding speed 0.2-0.3m / s, winding to the required thickness, continue to rotate until gel, send to curing oven for curing, curing temperature 90°C 2h+110°C 2h. After demoulding, use a diamond tool to process the external threads to obtain the upper threaded column 42, the middle threaded column 41 and the seat body 3. The process method is the same as above.

[0045] Such as Figure 7 and Figure 8 As shown, a groove 21 is set on one side of the gasket 2, and the groove 21 is filled with airgel, wherein the groove 21 is arranged in such a way that the extension lines of the centerlines of all grooves 21 pass through the c...

Embodiment 3

[0050] Such as Figure 7 and Figure 9 As shown, in this embodiment, the gasket 2 is provided with the grooves 21 described in the third embodiment on both sides, and the grooves 21 are filled with airgel, and the grooves 21 on both sides are set correspondingly. , to ensure the strength of gasket 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| winding tension | aaaaa | aaaaa |

| winding tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com