Device and method for evaluating desulfurizing effect of desulfurizing agent

An evaluation method and technology of evaluation devices, which are applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of poor reliability of evaluation results and inability to simulate the real flow conditions of wellbore, and achieve reliable evaluation results, improved reliability, and high measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

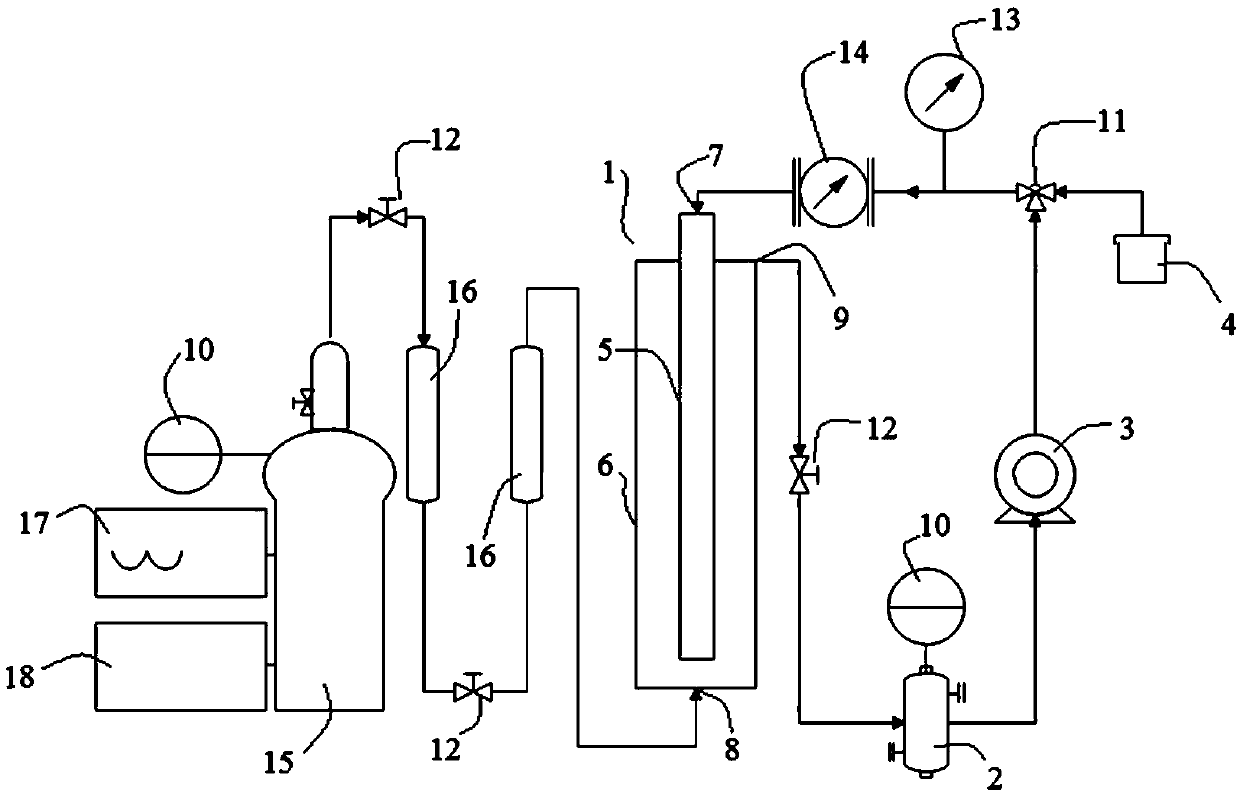

Method used

Image

Examples

Embodiment 1

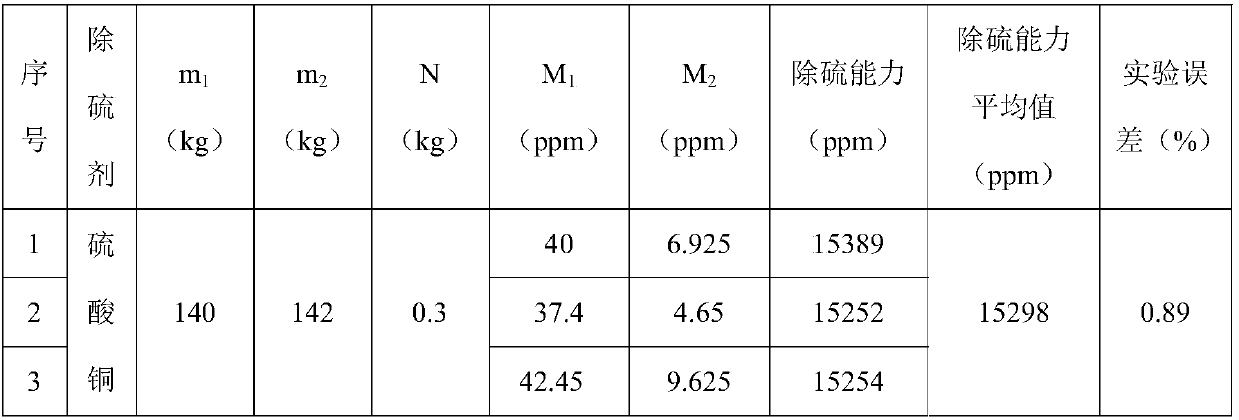

[0036] Embodiment 1 of the desulfurizing agent desulfurizing effect evaluation method of the present invention utilizes the desulfurizing agent desulfurizing effect evaluation device of the above embodiment to evaluate the desulfurizing effect of copper sulfate, comprising the following steps:

[0037] Prepare 150 kg of well killing fluid (the formula of well killing fluid is: 5wt% corrosion inhibitor, 2wt% fluid loss reducer, 1wt% surfactant and the remaining water), and add the prepared well killing fluid solution to the liquid distribution tank 4 40L hydrogen sulfide test gas (composed of hydrogen sulfide and air, the concentration of hydrogen sulfide is 100ppm) is injected from the gas inlet 8 into the mixing chamber of the simulated wellbore device 1 through the liquid inlet channel, and the well killing gas is injected from the liquid distribution tank 4 Liquid 140kg(m 1 ), the gas-liquid mixed fluid composed of killing fluid and hydrogen sulfide test gas fills the mixin...

Embodiment 2

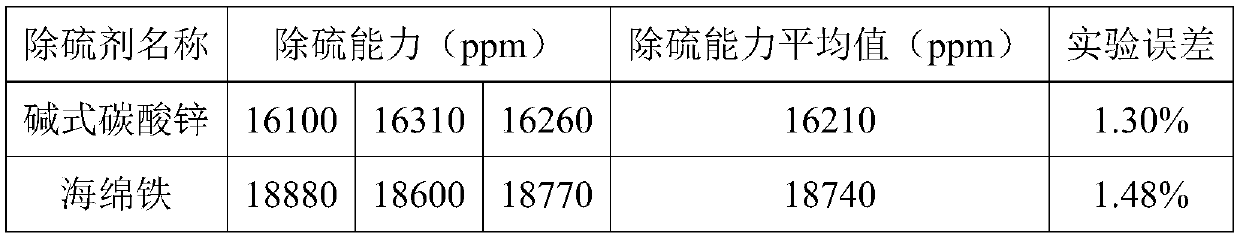

[0048] The evaluation results of Example 2 and Example 3 are summarized in Table 2.

[0049] Table 2 Evaluation of sulfur removal effect of basic zinc carbonate and sponge iron

[0050]

[0051] As can be seen from the experimental results in Table 2, the desulfurization capacity detection values of the same desulfurizer are basically the same, with a maximum error of 1.48%. The detection repeatability is good. As far as copper sulfate, basic zinc carbonate, and sponge iron are concerned, sponge iron has the strongest desulfurization ability, followed by basic zinc carbonate, and copper sulfate has the worst desulfurization effect.

[0052] The embodiment of the above evaluation method is to utilize the following dynamic evaluation method to realize the desulfurization ability evaluation of the desulfurizer in essence, that is to add a certain quality of working liquid and hydrogen sulfide test gas into a closed circulation loop to make the working liquid and hydrogen su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com