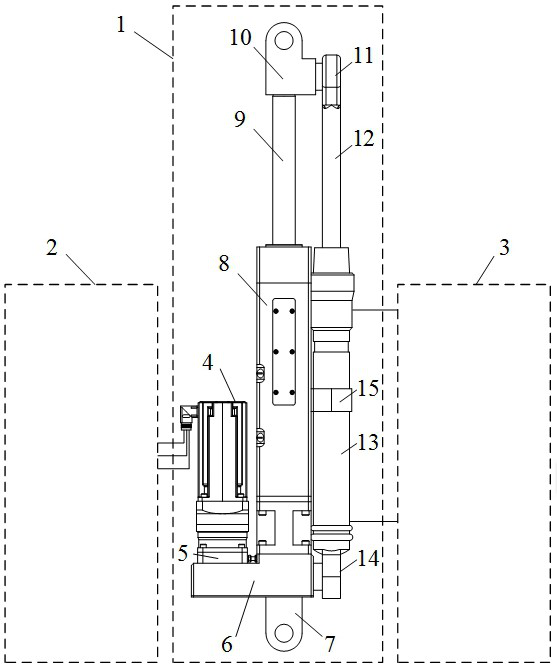

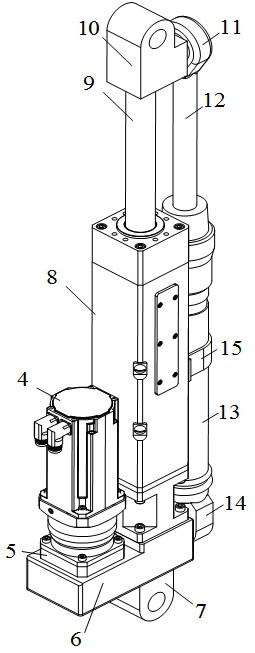

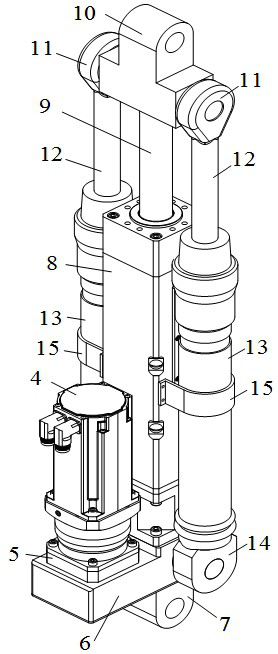

An integrated electromechanical-hydraulic drive and energy storage integrated actuating device

An actuating device and hydraulic actuating technology, applied in the direction of electromechanical devices, circuit devices, battery circuit devices, etc., can solve the problems of larger space occupied by motors, weak carrying capacity, poor economy, etc., achieve high power density and improve load carrying capacity The effect of strong ability and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] as attached Figure 4 Shown is an integrated electromechanical-hydraulic drive and energy storage integrated actuating device, the connection mode of the integrated electromechanical-hydraulic actuator 1 and figure 1 The same, so no more details. Electromechanical drive and energy storage system 2 includes inverter 16, smoothing capacitor 17, DC bus 18, rectifier 19, three-phase alternating current 20, DC-DC converter 21, super capacitor 22, hydraulic drive and energy storage system in 3 packages Including two-position three-way valve 23, accumulator 24, two-position two-way valve 25, first one-way valve 26, second one-way valve 27, three-position four-way valve 28, oil tank 29, asynchronous motor 30, variable hydraulic pressure Pump 31, safety valve 32.

[0032] In the electromechanical drive and energy storage system, the output of the inverter is connected to the power line, the input of the inverter is connected to the output of the rectifier through the DC bus, t...

Embodiment 2

[0036] as attached Figure 5 As shown, an integrated electromechanical-hydraulic drive and energy storage integrated actuating device is shown. The electromechanical drive and energy storage system of another embodiment is the same as that of Embodiment 1, so it will not be described in detail. In the hydraulic drive and energy storage system, the large cavity of the hydraulic cylinder is directly connected to the accumulator, and the small cavity of the hydraulic cylinder is directly connected to the fuel tank. This embodiment can be applied in machines where there is only resistive extension and overriding retraction conditions, such as excavator booms, forklifts, and the like. During the working process, pre-charge the accumulator with pre-charging pressure, the servo motor and the accumulator jointly drive the push rod of the actuator to extend, when the push rod retracts, the external kinetic energy or potential energy can be converted into hydraulic energy directly Stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com