Near-infrared-curable ink composition, near-infrared-curable film, method for producing them, and optical modeling method

An ink composition, near-infrared technology, applied in the direction of ink, processing and manufacturing, manufacturing tools, etc., can solve problems such as hindering curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

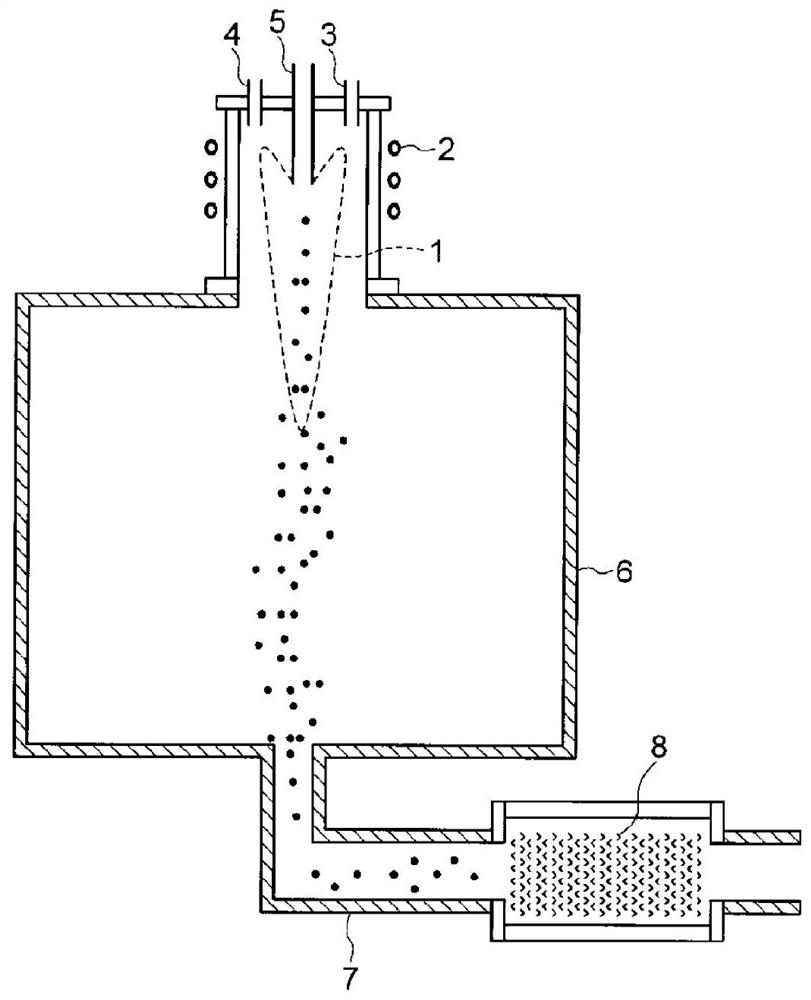

Method used

Image

Examples

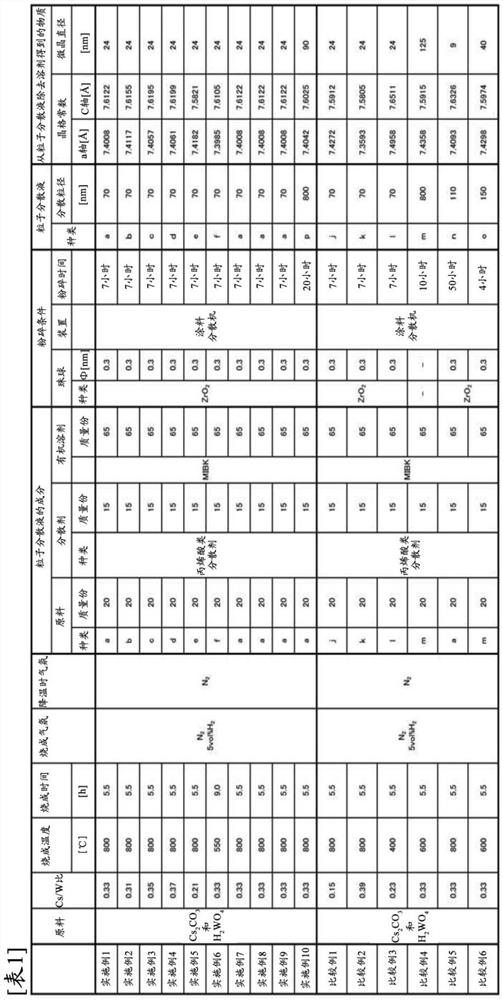

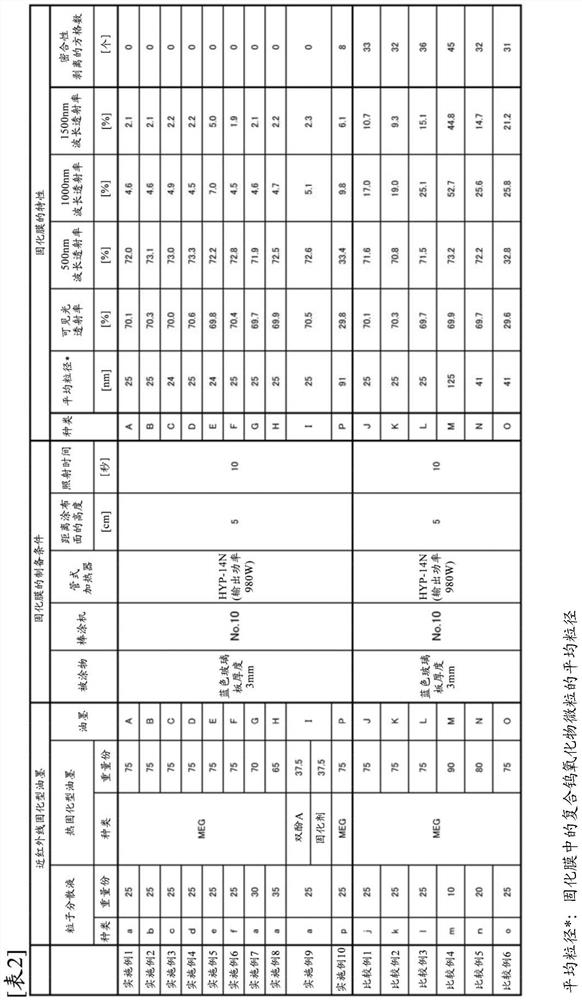

Embodiment 1

[0300] Dissolve cesium carbonate (Cs 2 CO 3 ) 7.43kg to obtain a solution. This solution was added to tungstic acid (H 2 WO 4 ) 34.57kg and mix well with stirring, then stir and dry (the molar ratio of W to Cs is equivalent to 1:0.33). N is supplied to the dried product 2 5 vol% H with gas as carrier 2 The gas was fired at a temperature of 800°C for 5.5 hours while heating, and thereafter, the supply gas was switched to N only 2 The gas was cooled to room temperature to obtain composite tungsten oxide particles (hereinafter referred to as particles a).

[0301] A mixture was obtained by mixing 20 parts by mass of particles a, 65 parts by mass of methyl isobutyl ketone, and 15 parts by mass of an acrylic dispersant. The mixture was filled with 0.3 mmφZrO added 2 A bead paint disperser (manufactured by Asada Iron Works Co., Ltd.) was subjected to pulverization and dispersion treatment for 7 hours to obtain a fine particle dispersion liquid (hereinafter referred to as a f...

Embodiment 2

[0312]Except for weighing predetermined amounts of tungstic acid and cesium carbonate, except that the molar ratio of W and Cs was 1:0.31, the same operation as in Example 1 was carried out to obtain Cs tungsten oxide fine particles of Example 2 (hereinafter referred to as Particles b).

[0313] Except having used the fine particle b instead of the fine particle a, it carried out similarly to Example 1, and obtained the dispersion liquid of the fine particle b (hereinafter, referred to as the fine particle dispersion liquid b).

[0314] Next, except that the fine particle dispersion liquid b was used instead of the fine particle dispersion liquid a, the same operation as in Example 1 was carried out to prepare a near-infrared curable ink of Example 2 (hereinafter referred to as ink B).

[0315] Except having used ink B instead of ink A, it carried out similarly to Example 1, and obtained the cured film of Example 2 (referred to as a cured film B hereinafter).

[0316] The fin...

Embodiment 3

[0319] Except that the tungstic acid and cesium carbonate of the predetermined amount were weighed to make the molar ratio of W and Cs 1:0.35, the same operation as in Example 1 was carried out to obtain Cs tungsten oxide fine particles of Example 3 (hereinafter referred to as Particles c).

[0320] Except having used the fine particle c instead of the fine particle a, it carried out similarly to Example 1, and obtained the dispersion liquid of the fine particle c (hereinafter referred to as the fine particle dispersion liquid c).

[0321] Next, except that the fine particle dispersion liquid c was used instead of the fine particle dispersion liquid a, the same operation as in Example 1 was carried out to prepare a near-infrared curable ink of Example 3 (hereinafter referred to as ink C).

[0322] Except having used ink C instead of ink A, it carried out similarly to Example 1, and obtained the cured film of Example 3 (referred to as a cured film C hereinafter).

[0323] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com