Sustained-release gel material with double-effect drug loading function as well as preparation method and application thereof

A slow-release gel and drug-loading technology, which is applied in the fields of botany equipment and methods, applications, chemicals for biological control, etc., can solve the long-lasting effect period, the coating rate is not high enough, and the slow-release requirements Limitations and other issues, to achieve the effect of accelerating the degradation rate, easy access to raw materials, and improving mechanical properties and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

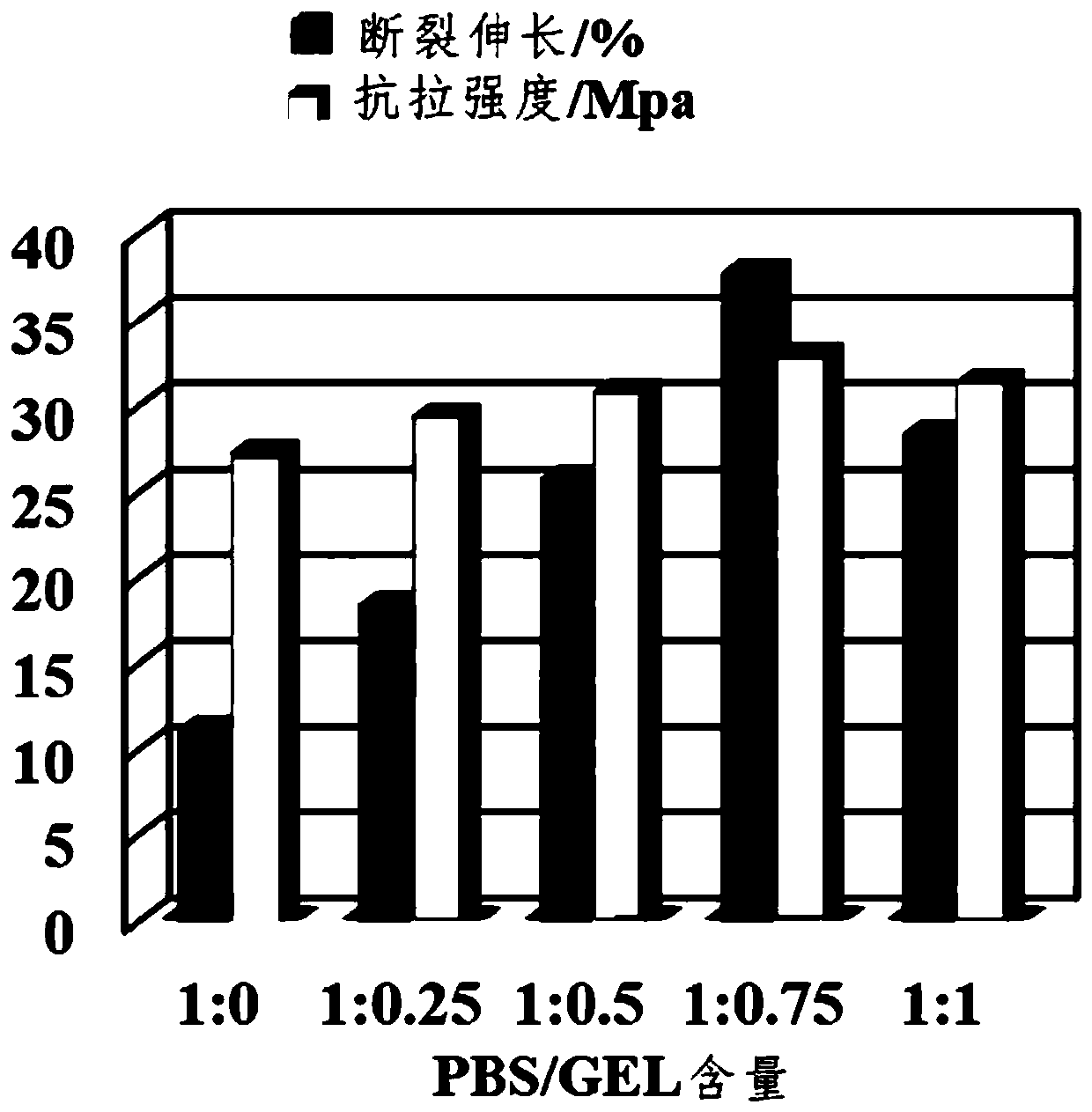

Method used

Image

Examples

Embodiment 1

[0049] The preparation of the biodegradable sustained-release gel film with dual-effect drug-loading function includes:

[0050] Step 1: Weigh 5g of polylactic acid (PLA) and dissolve it in 15mL of chloroform until it is completely dissolved. After standing for 24 hours, the PLA molecular chain is completely stretched, and then add 0.15mL of imidacloprid into the dissolved PLA chloroform solution for use;

[0051] Step 2: Weigh 0.2g of Span 80 and stir at 40°C for 30min to dissolve in 100mL of distilled water to obtain a continuous aqueous phase for use;

[0052] Step 3: slowly pour the organic phase obtained in step 1 into the continuous water phase obtained in step 2, and emulsify at a high speed of 1000r / min for 0.5h to form an O / W emulsion. Add antifoaming agent and stir for 6 hours at 50°C. With the slow volatilization of chloroform, PLA gradually settles to form a suspension of PLA drug-loaded microspheres;

[0053] Step 4: Weigh 1g of gelatin at 40°C and stir at a spee...

Embodiment 2

[0058] The preparation of the biodegradable sustained-release gel film with dual-effect drug-loading function includes:

[0059] Step 1: Weigh 5g of polylactic acid (PLA) and dissolve it in 20mL of chloroform until it is completely dissolved. After standing for 20 hours, the PLA molecular chain is completely stretched, and then add 0.2mL of imidacloprid into the dissolved PLA chloroform solution for use;

[0060] Step 2: Weigh 0.2g of Span 80 and stir at 40°C for 30min to dissolve in 150mL of distilled water to obtain a continuous aqueous phase for use;

[0061] Step 3: slowly pour the organic phase obtained in step 1 into the continuous water phase obtained in step 2, and emulsify at a high speed of 1200r / min for 0.6h to form an O / W emulsion. Add antifoaming agent and stir for 5 hours at 30°C. With the slow volatilization of chloroform, PLA gradually settles to form a suspension of PLA drug-loaded microspheres;

[0062] Step 4: Weigh 1g of gelatin at 50°C and stir at a speed...

Embodiment 3

[0067] The preparation of the biodegradable sustained-release gel film with dual-effect drug-loading function includes:

[0068] Step 1: Weigh 10g of polylactic acid (PLA) and dissolve it in 20mL of chloroform until it is completely dissolved. After standing for 24 hours, the PLA molecular chain is completely stretched, and then add 0.15mL of imidacloprid into the dissolved PLA chloroform solution for use;

[0069] Step 2: Weigh 0.1g of Span 80 and stir at 40°C for 30min to dissolve in 100mL of distilled water to obtain a continuous aqueous phase for use;

[0070] Step 3: slowly pour the organic phase obtained in step 1 into the continuous water phase obtained in step 2, and emulsify at a high speed of 1500r / min for 0.5h to form an O / W emulsion. Add antifoaming agent at 80°C and stir for 10 hours. With the slow volatilization of chloroform, PLA gradually settles to form a suspension of PLA drug-loaded microspheres;

[0071] Step 4: Weigh 1g of gelatin at 20°C and stir at a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com