Separation device and separation method for triethylene diamine and ethanolamine

A technology of triethylenediamine and separation device, applied in the chemical industry, can solve the problems of cooling, poor filtering effect, long extraction time, complicated operation, etc., and achieve the effect of improving filtering efficiency, cooling efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

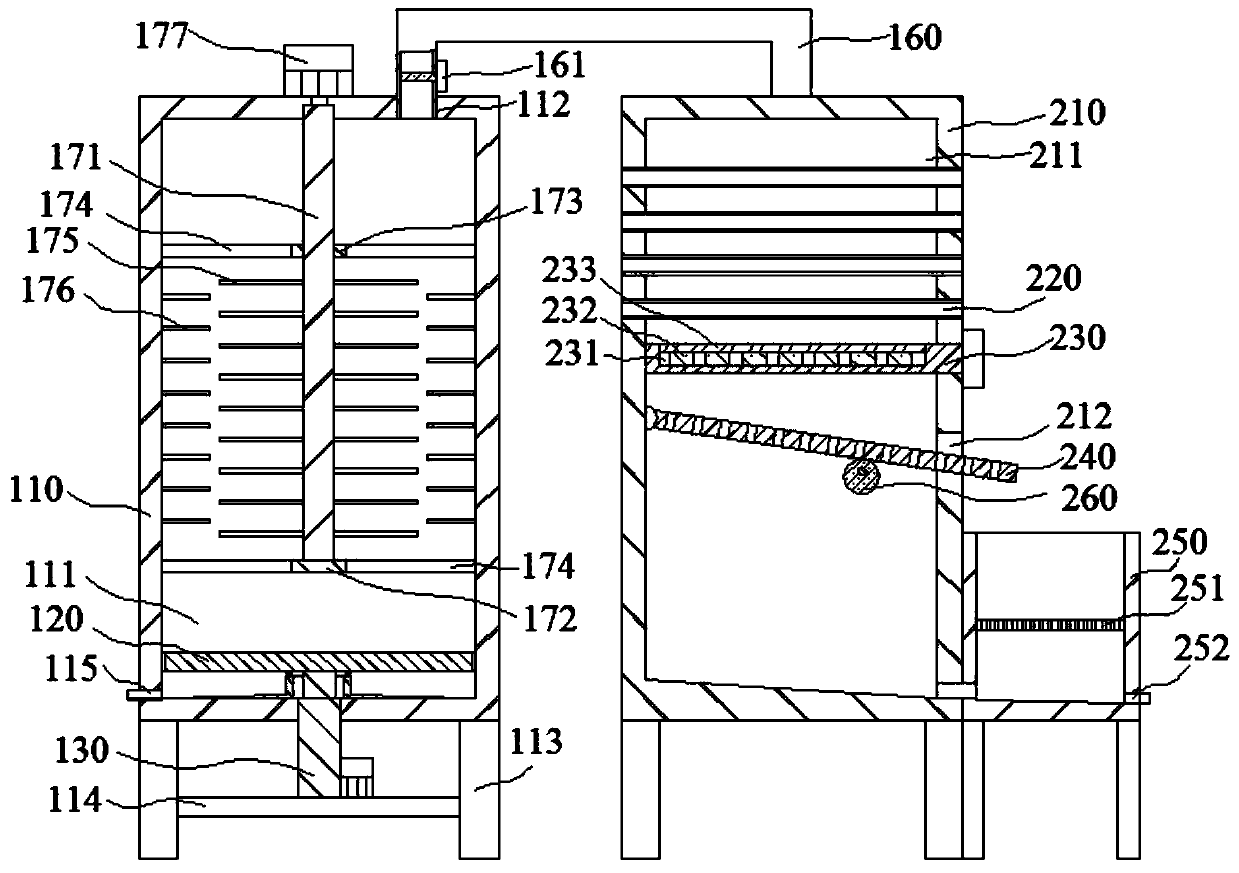

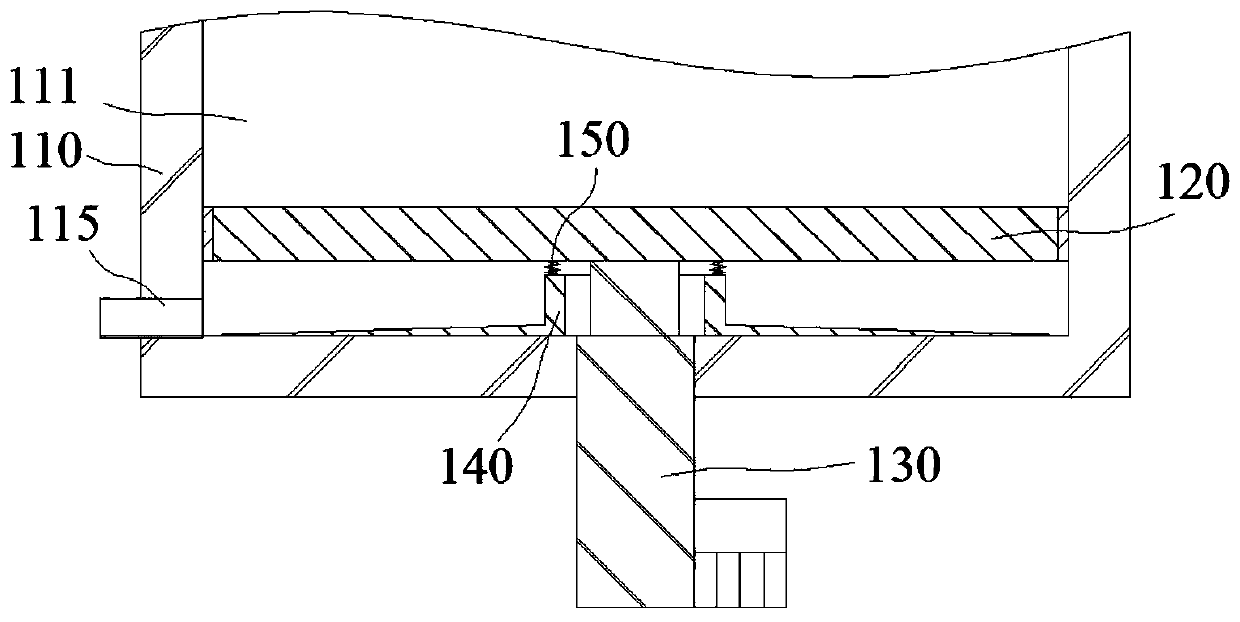

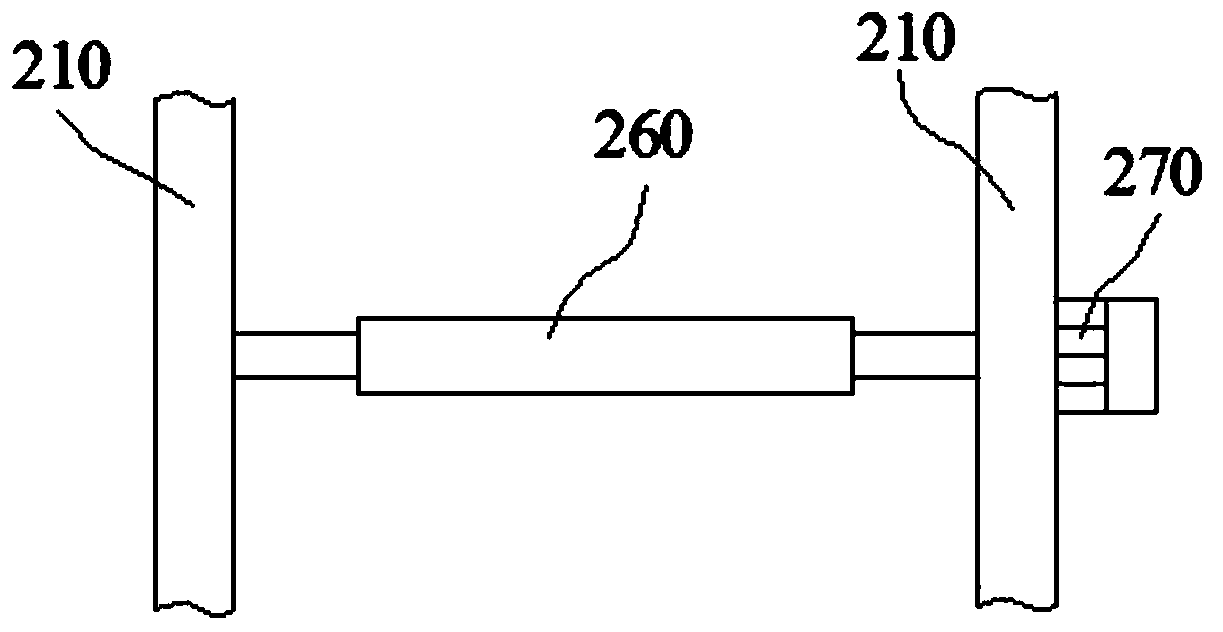

[0036] Such as figure 1 , figure 2 with image 3 As shown, this embodiment provides a separation device for triethylenediamine and ethanolamine, which includes an extraction tower 110, an extraction chamber 111 is provided in the extraction tower 110, a sealing plate 120 is provided at the bottom of the extraction chamber 111, and a sealing plate 120 is provided at the bottom end is connected with the movable rod of an electric lifting rod 130, and the rod body of the electric lifting rod 130 passes through the bottom of the extraction tower 110; The surface is connected with an organ cover 150, and the top of the organ cover 150 is connected with the bottom surface of the sealing plate 120; the top of the extraction tower 110 is provided with a light phase liquid outlet 112, and the light phase liquid outlet 112 is connected with a processing device 210 through a pipeline 160, and the inside of the processing device 210 A processing chamber 211 is provided, and a plurality...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com