Large-section laminated wood manufactured from undersized logs and manufacturing method thereof

A manufacturing method and technology of glued wood, applied in the jointing of wooden veneers, manufacturing tools, making finger joints, etc., can solve the problems of cumbersome procedures and achieve the effects of simplified procedures, excellent mechanical strength and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

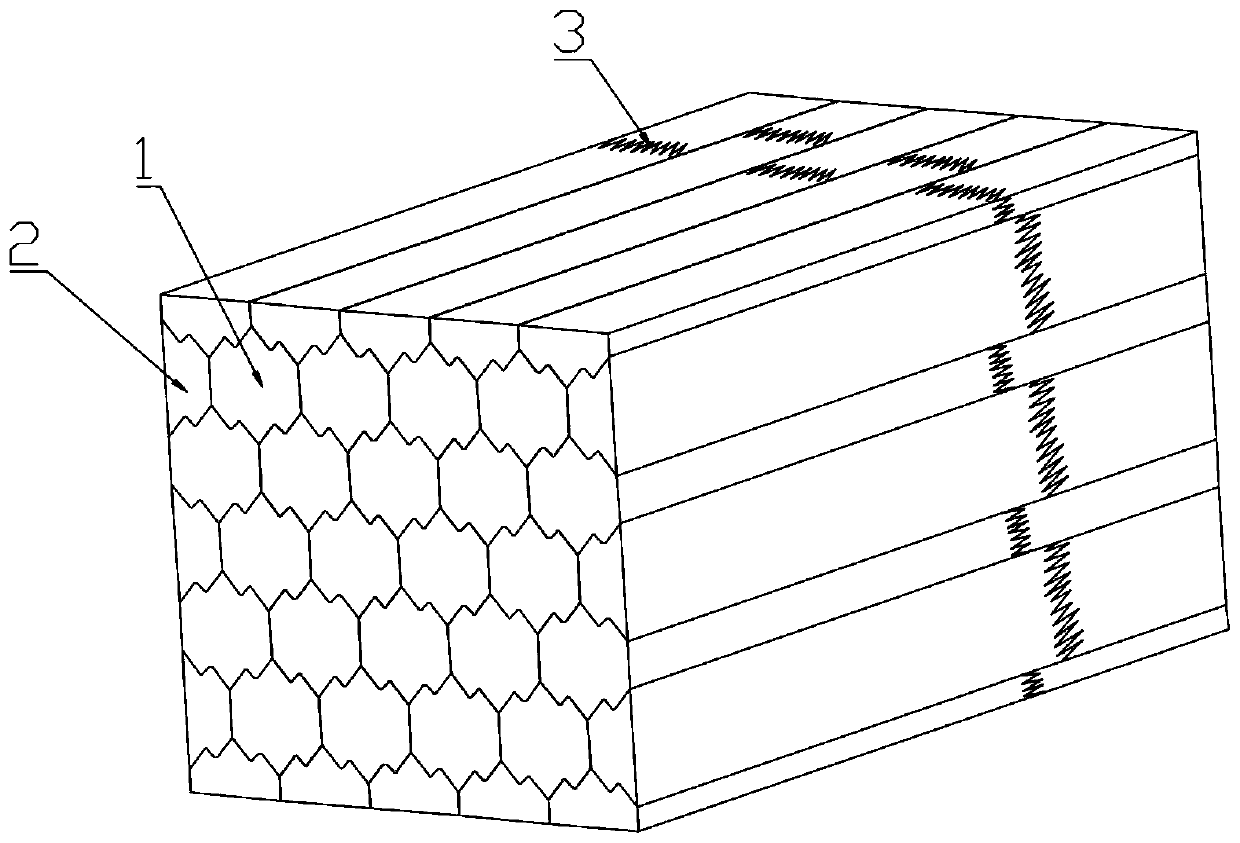

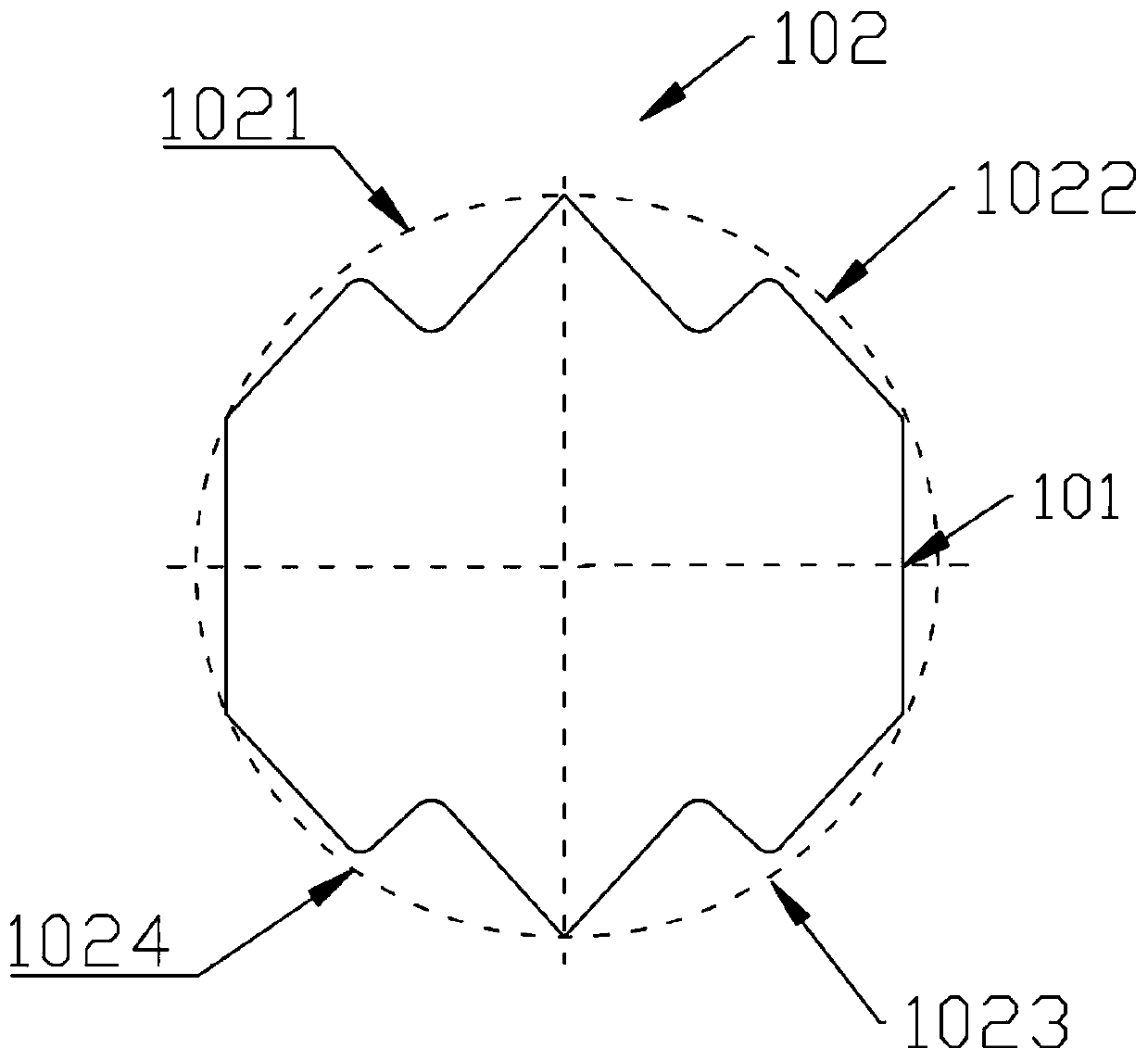

[0036] Such as figure 1 , figure 2 as well as image 3 As shown, a large-section glued wood made of small-diameter wood includes a glued wood body. Polygonal prism 1 comprises a opposite side plane 101 and the sawtooth surface 102 that are parallel to each other and the path length is equal, and the sawtooth surface 102 comprises the upper and lower sawtooth surfaces that are arranged oppositely, and the upper sawtooth surface is composed of the first sawtooth surface 1021, the second sawtooth surface 1022, the lower serrated surface is composed of the third serrated surface 1023 and the fourth serrated surface 1024, the first serrated surface 1021 is consistent with the third serrated surface 1023; the second serrated surface 1022 and the fourth serrated surface 1024 consistent;

[0037] The half-toothed polygonal prism 2 is obtained by symmetrically cutting the two opposite side planes 101 of the toothed polygonal prism 1 by a vertical plane.

Embodiment 2

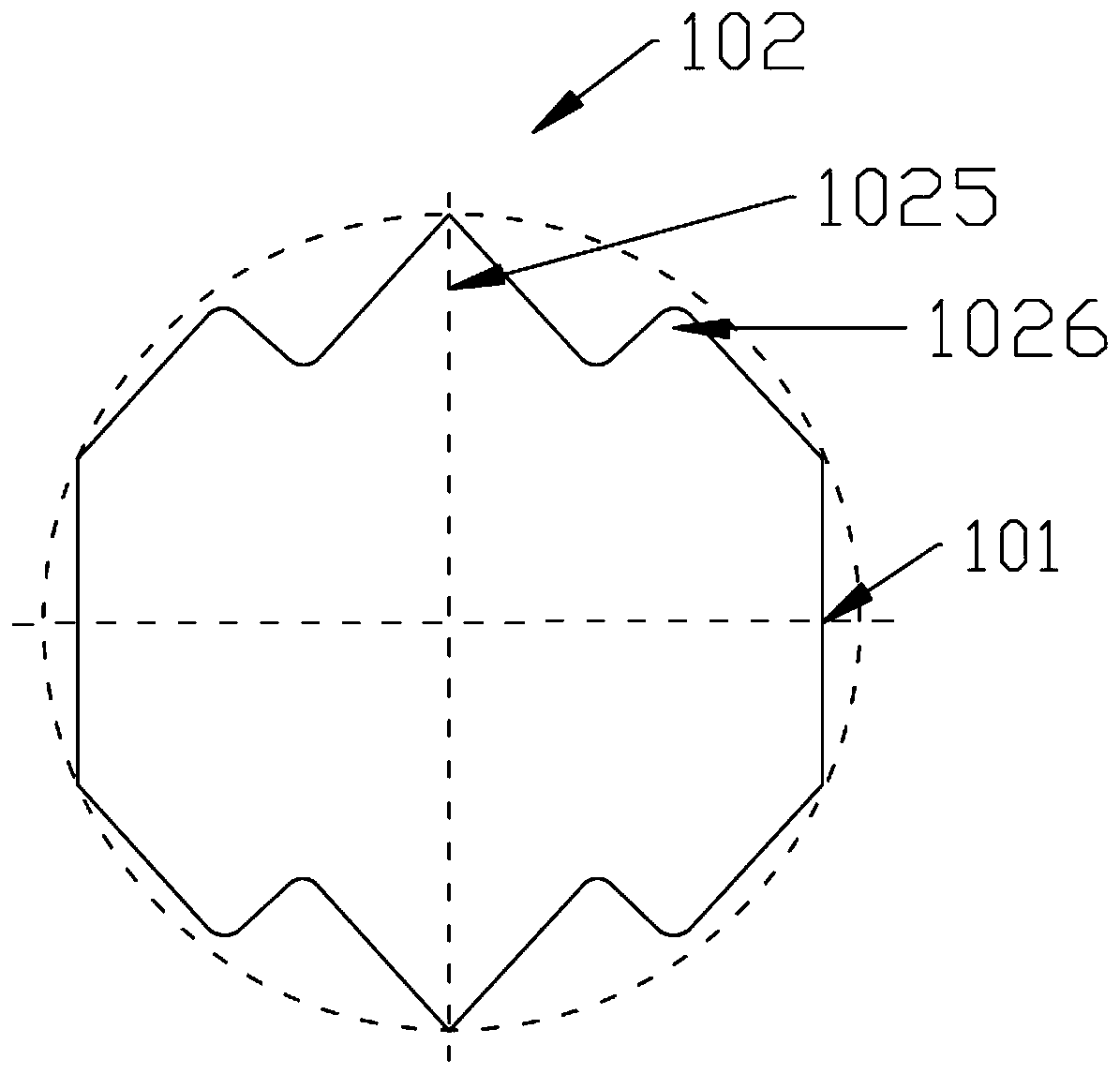

[0039] This embodiment is a further optimization made on the basis of Embodiment 1. Specifically, the upper and / or lower serrated surfaces are provided with at least three odd-numbered serrations, preferably 3 or 5, such as Figure 7 shown.

[0040] Specifically, the serrated surface 102 includes an apex angle 1025 and an intersection angle 1026, the apex angle 1025 is 30-120°, the intersection angle 1026 is 30-120°, preferred values: an apex angle of 60° and an intersection angle of 60°.

[0041] Specifically, the vertex of the vertex 1025 is located on the same circumference as the vertex on the cross-section of the side plane 101 .

Embodiment 3

[0043] A method for manufacturing large-section glued laminated wood, comprising the following steps:

[0044] S1: wooden section preparation: first cut the small wooden diameter into 50cm long wooden section, then dry the wooden section to obtain a spare wooden section, the diameter of the small diameter wood is 5mm, the moisture content of the spare wooden section in the step S1 10%.

[0045] S2: Processing of toothed polygonal prism 1;

[0046] Using an alloy knife cutting saw equipment to process the spare wood section to obtain a toothed polygonal column 1;

[0047] S3: Processing of half-toothed polygonal prism 2;

[0048] Perform symmetrical sawing on the vertical planes of the two opposite side planes of the tooth-shaped polygonal prism 1 obtained in step S2 to obtain a half-toothed polygonal prism 2;

[0049] S4: Forming process: Process the two ends of the toothed multi-prism 1 into finger joints 3, apply glue on the finger joints 3 at the end of the toothed multi-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap