Granular full-degradable environment-friendly starch and modified starch master batch and production method thereof

A modified starch and production method technology, applied in the field of material processing, can solve the problems of hidden dangers of hygiene, inconvenient and accurate measurement, etc., and achieve the effects of improving efficiency, simplifying operation and prolonging residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

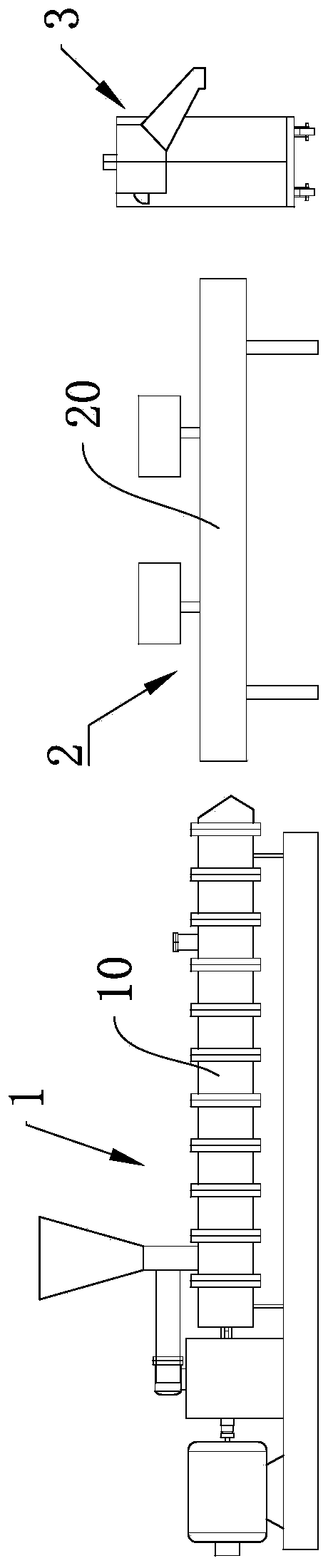

Method used

Image

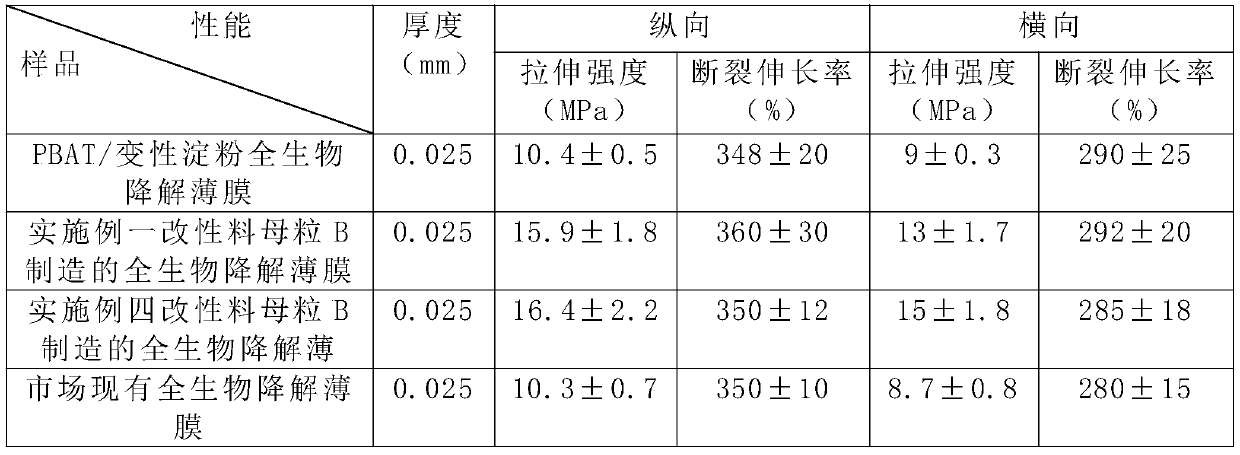

Examples

Embodiment 1

[0025] Put 2kg of glycerin and 8kg of denatured starch into a high-speed mixer and mix thoroughly, then put the mixture into a twin-screw extruder, set the temperature of the twin-screw to 50-160°C, and the speed of the main engine to 200rpm. After extrusion, the material enters a 1m-long Air-cooled towline, then pelletized and packaged to obtain modified starch masterbatch A.

[0026] Put 3kg of modified starch masterbatch A, 6kg of polybutylene adipate terephthalate (PBAT) and 1kg of erucamide into a high-speed mixer and mix them thoroughly, then add the mixture into a twin-screw extruder, set The twin-screw temperature is set at 50-170°C, the host speed is 150rpm, and the material is extruded, pelletized, and packaged to obtain the modified masterbatch B.

Embodiment 2

[0028] Put 2kg of sorbitol and 10kg of starch into a high-speed mixer and mix thoroughly, then put the mixture into a twin-screw extruder, set the temperature of the twin-screw to 50-160°C, and the speed of the main engine to 200rpm. After extrusion, the material enters a 1.2m long Air-cooled towline, then pelletized and packaged to obtain starch masterbatch A.

[0029] 3kg starch masterbatch A, 6kg polybutylene adipate terephthalate (PBAT) and 1kg polyester chain extender are put into high-speed mixer and fully stirred and mixed, then the mixture is added in the twin-screw extruder, Set the temperature of the twin-screw to 50-170°C, and the speed of the host to 150rpm. The material is extruded, pelletized, and packaged to obtain the modified masterbatch B.

Embodiment 3

[0031] Put 2kg of urea and 18kg of starch into a high-speed mixer and mix thoroughly, then put the mixture into a twin-screw extruder, set the temperature of the twin-screw to 50-160°C, and the speed of the main engine to 200rpm. After extrusion, the material enters a 0.8m long Air-cooled towline, then pelletized and packaged to obtain starch masterbatch A.

[0032] Put 3kg of starch masterbatch A, 6kg of polybutylene adipate terephthalate (PBAT) and 1kg of additives into a high-speed mixer to fully stir and mix. The additives are glycerin, erucamide, polyester chain extension The mixture is composed of 1:2:1 mass ratio, and then the mixture is added into the twin-screw extruder, the twin-screw temperature is set at 50-170°C, the host speed is 150rpm, and the material is extruded, pelletized, and packaged to obtain Modified masterbatch B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com