Superhard aggregate abrasive with high micro-crushing characteristic and preparation method thereof

A kind of aggregation and micro-crushing technology, which is applied in the field of abrasive processing (grinding, honing, abrasive preparation, grinding, polishing) to achieve the effect of improving quality, stabilizing processing efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

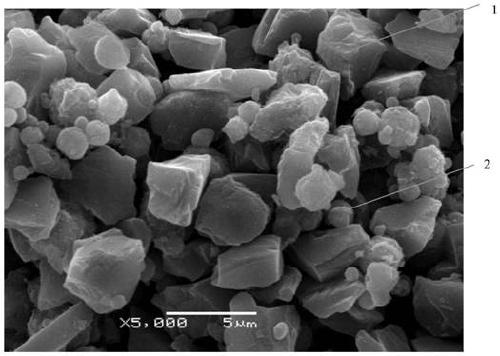

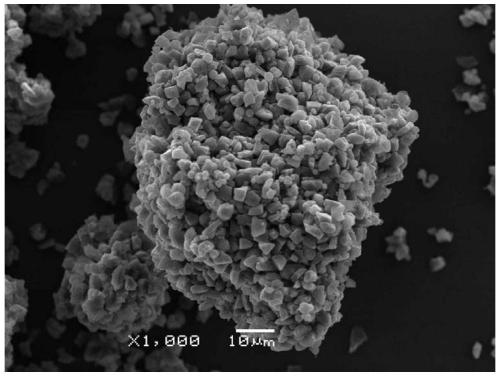

[0027] Such as Figure 1~2 shown.

[0028] A superhard aggregate abrasive with high micro-fracture characteristics, which is made of 7-14 μm diamond powder, highly brittle germanium bond and brittle modifier copper powder, and its preparation method is: diamond, high brittle bond Fully mix with copper powder in the ratio of 80:15:5 by mass, add polyvinyl acetate binder (6% of the mass of the mixture) to the mixture, and then press the green body into the vacuum furnace (vacuum degree lower than 133Pa), degumming at 350°C for 0.5 hours at medium temperature and sintering at 950°C for 2 hours at high temperature; then crushing and grading to obtain superhard aggregate abrasive grains with high micro-fracture characteristics. The superhard aggregate abrasive grains with a particle size of 10-150 μm are used to prepare resin grinding wheels. When grinding ferrite magnetic workpieces, the workpiece surface roughness Ra is better than 100nm, and the processing performance is stable...

Embodiment 2

[0030] A superhard aggregate abrasive with high micro-fracture characteristics, which is made of 3-5 μm diamond, high brittle silicon alloy powder binder and brittle regulator aluminum powder, and its preparation method is: diamond, high brittle binder Fully mix with aluminum powder at a ratio of 75:20:5 by mass, add polyvinyl acetate binder (10% of the mass of the mixture) to the mixture, and then press the green body, put it into a vacuum furnace, and heat it at 450 Degumming at medium temperature for 2 hours and high temperature sintering at 850℃ for 3 hours. The vacuum degree of the vacuum furnace is controlled at 133Pa or below; then crushing and grading are carried out to obtain superhard aggregate abrasive grains with high micro-fracture characteristics. Among them, 15-100 μm superhard aggregate abrasive grains are used to prepare a fixed abrasive resin grinding pad. When grinding mobile phone glass panels, the surface roughness Ra of the workpiece is better than 150nm, ...

Embodiment 3

[0032] A superhard aggregate abrasive with high micro-fracture characteristics and a preparation method thereof, which is made of 10-14 μm cubic boron nitride abrasive, a highly brittle silicon alloy powder binder and a brittle regulator aluminum alloy powder, and the preparation method For: Cubic boron nitride abrasive, highly brittle binder and aluminum alloy powder are fully mixed in a ratio of 70:20:10 by mass, and polyvinyl alcohol binder (8% of the mass of the mixture) is added to the mixture and stirred evenly After pressing the green body and putting it into a vacuum furnace, carry out medium temperature degumming at 400°C for 2 hours and high temperature sintering at 1000°C for 3 hours. The vacuum degree of the vacuum furnace is controlled at or below 133Pa; Superhard aggregate abrasive particles with micro-crushing properties. Among them, 10-150 μm superhard aggregate abrasive grains are used to prepare resin grinding wheels for grinding seamless steel pipes. The wor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com