Automatic early warning and monitoring device system for urban road underground collapse

An automatic early warning and monitoring device technology, applied in the direction of measuring devices, alarms, instruments, etc., can solve the problems of not being able to early warning, etc., and achieve the effect of reducing the impact of vibration, reducing impact and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

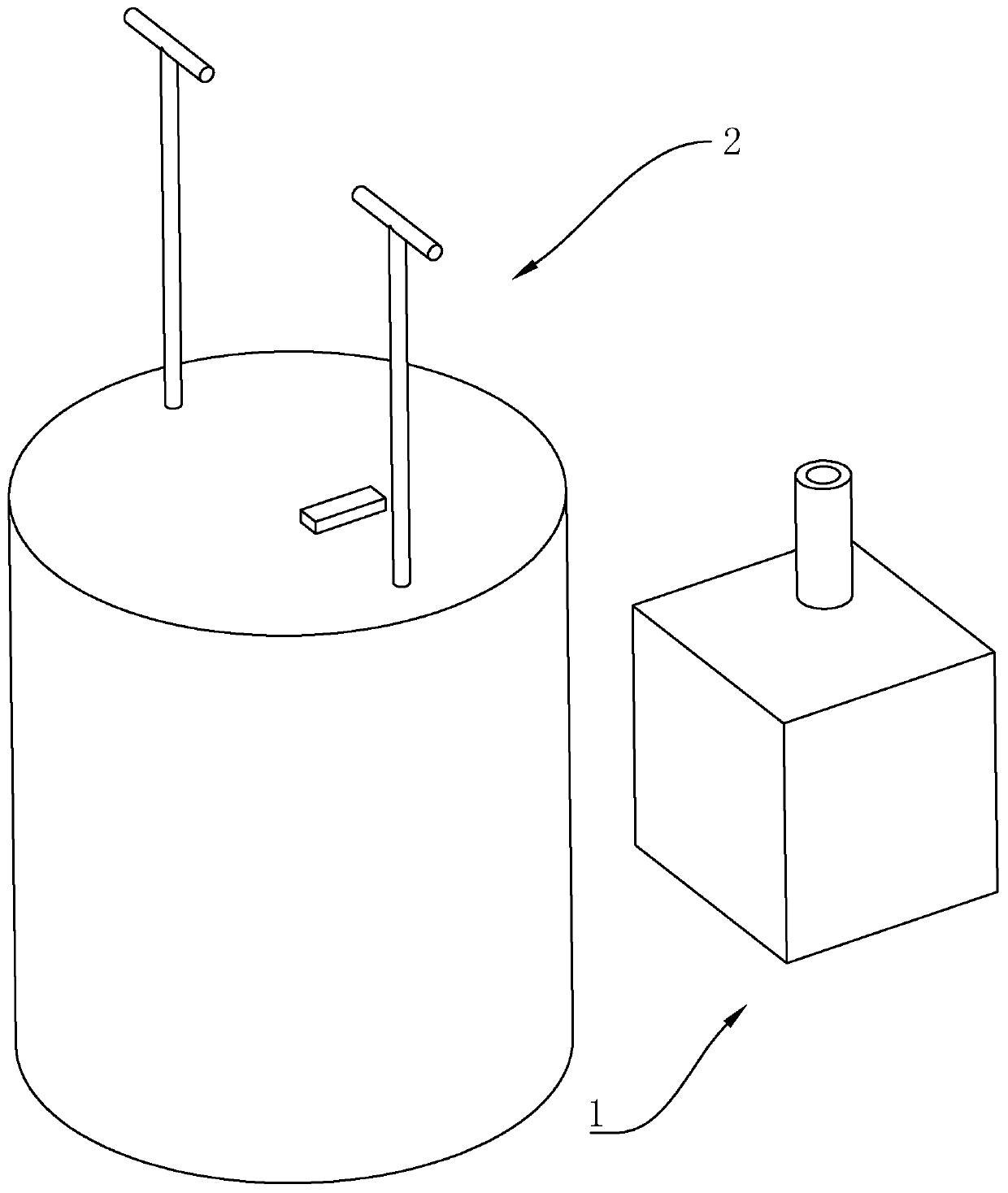

[0038] Embodiment 1: An automatic early warning and monitoring device system for underground subsidence of urban roads, such as figure 1 As shown, it includes an above-ground early-warning information receiver 1 and an underground early-warning device 2; the underground early-warning device 2 is arranged below the road structure layer, and the above-ground early-warning information receiver 1 and the underground early-warning device 2 are connected wirelessly. When the road subsides, The underground early warning device 2 starts automatically, and transmits the information of the subsidence to the ground early warning information receiver 1, so that the subsidence information of the road can be monitored in real time.

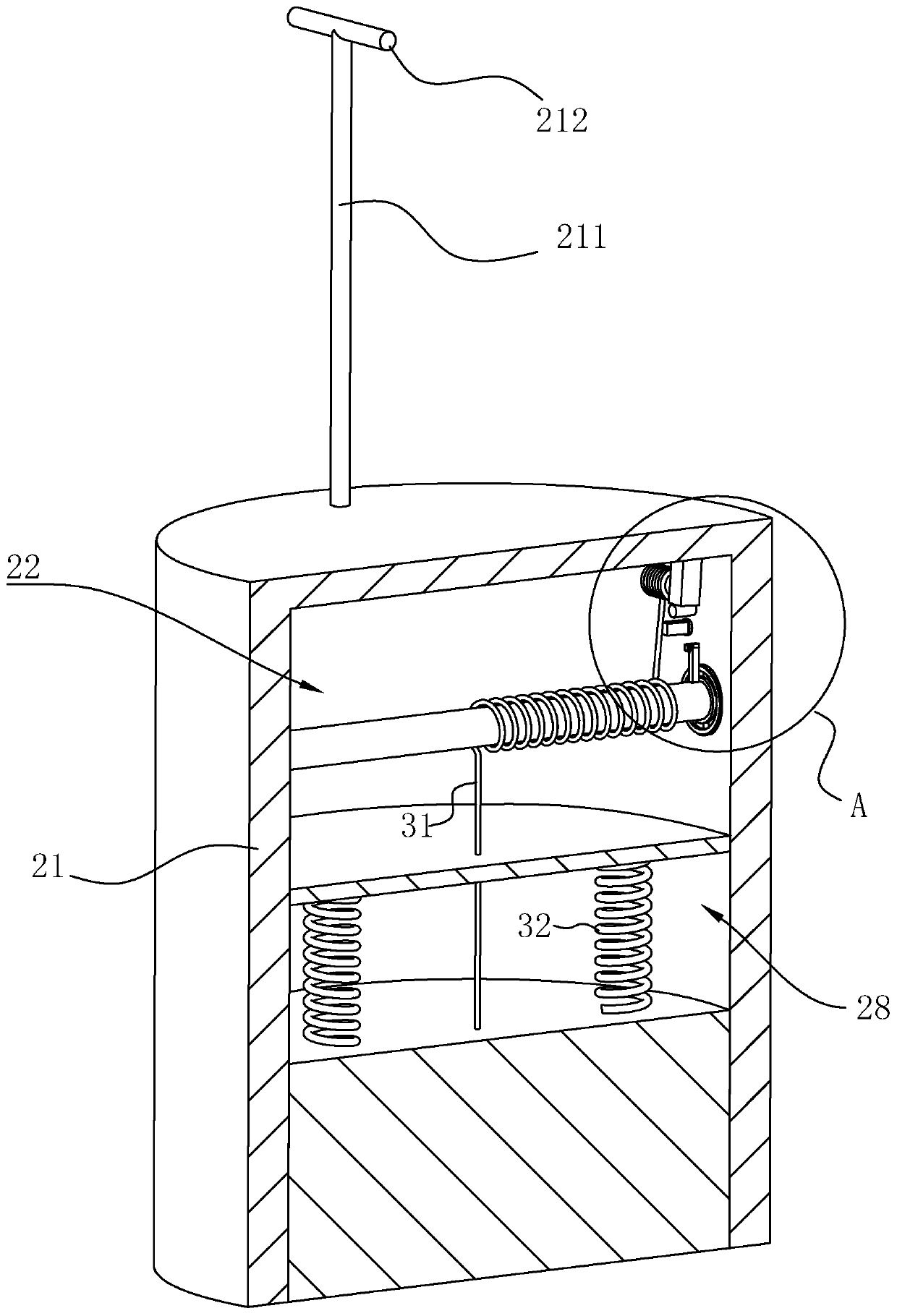

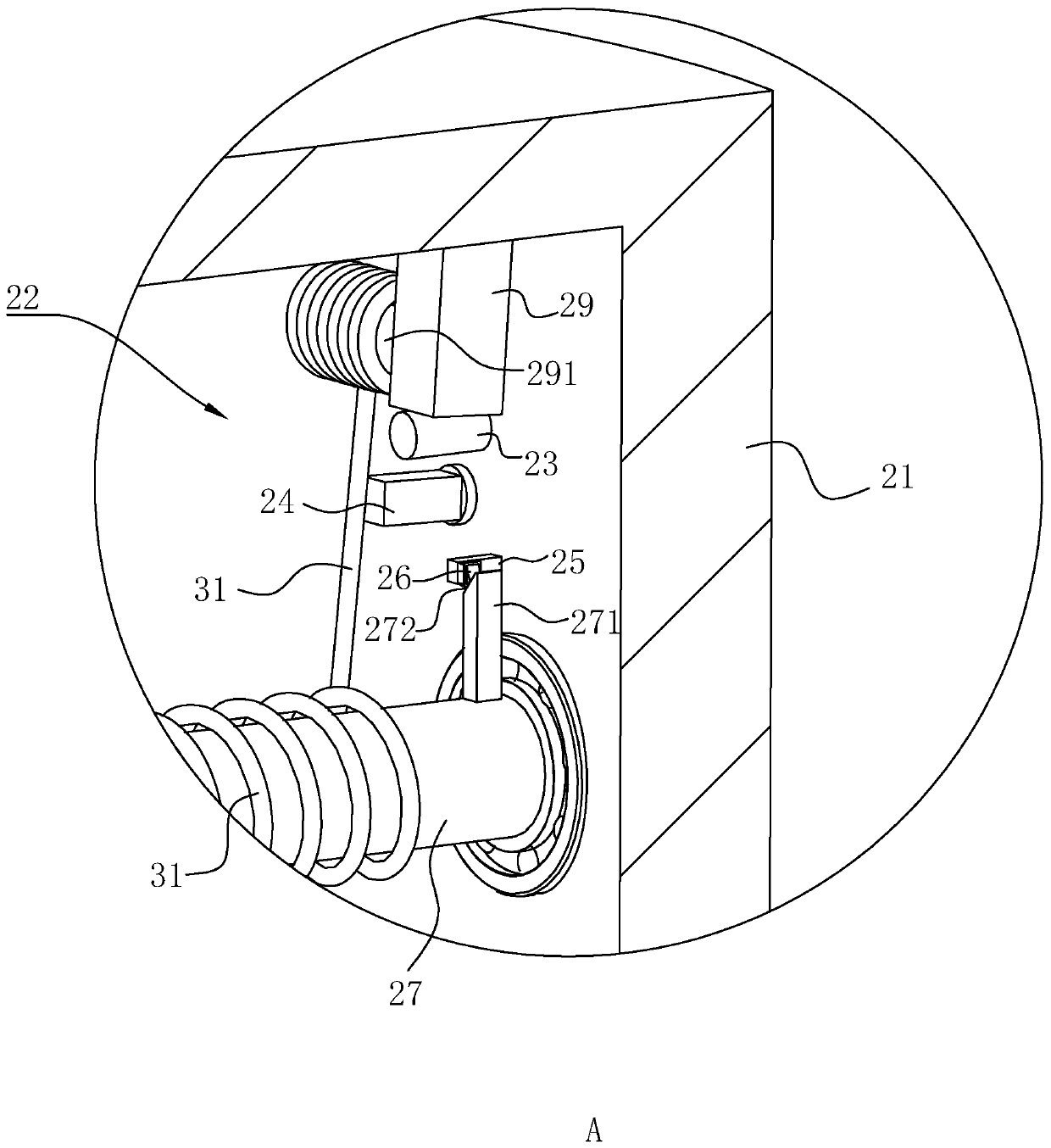

[0039] Such as figure 2 and image 3 As shown, the underground early warning device 2 includes a cylindrical main body 21 and a cavity 22 inside the main body 21, the cavity 22 is located at the upper half of the main body 21; the inner wall of the cavity 22...

Embodiment 2

[0045] Embodiment two: if Figure 4 As shown in Fig. 1, surface monitoring in conventional urban engineering requires drilling a monitoring hole on the road, passing a threaded steel bar through the monitoring hole to the underground of the road, and then pouring concrete to fill it, so that the steel bar and the road form an integral body. Observe the deformation of the road surface, but drilling monitoring holes will cause damage to the road, so a vertical steel pipe 4 is inserted on the main body 21, the steel pipe 4 is at the axis of the main body 21, and the steel pipe 4 runs through the main body 21, the cavity 22 and the The drop body 3 and the steel pipe 4 can be inserted through the steel bar, so that there is no need to drill additional monitoring holes and reduce damage to the road; The side wall is rotationally connected, and the transverse axis 27 does not pass through the steel pipe 4, so as to avoid affecting the insertion of the reinforcing bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com