Turbomachine fan flow-straightener vane, turbomachine assembly comprising such a vane, and turbomachine equipped with said vane or with said assembly

A technology of turbines and rectifiers, applied in the direction of supporting elements of blades, machines/engines, components of pumping devices for elastic fluids, etc., which can solve the problems of increasing vortex phenomena, noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

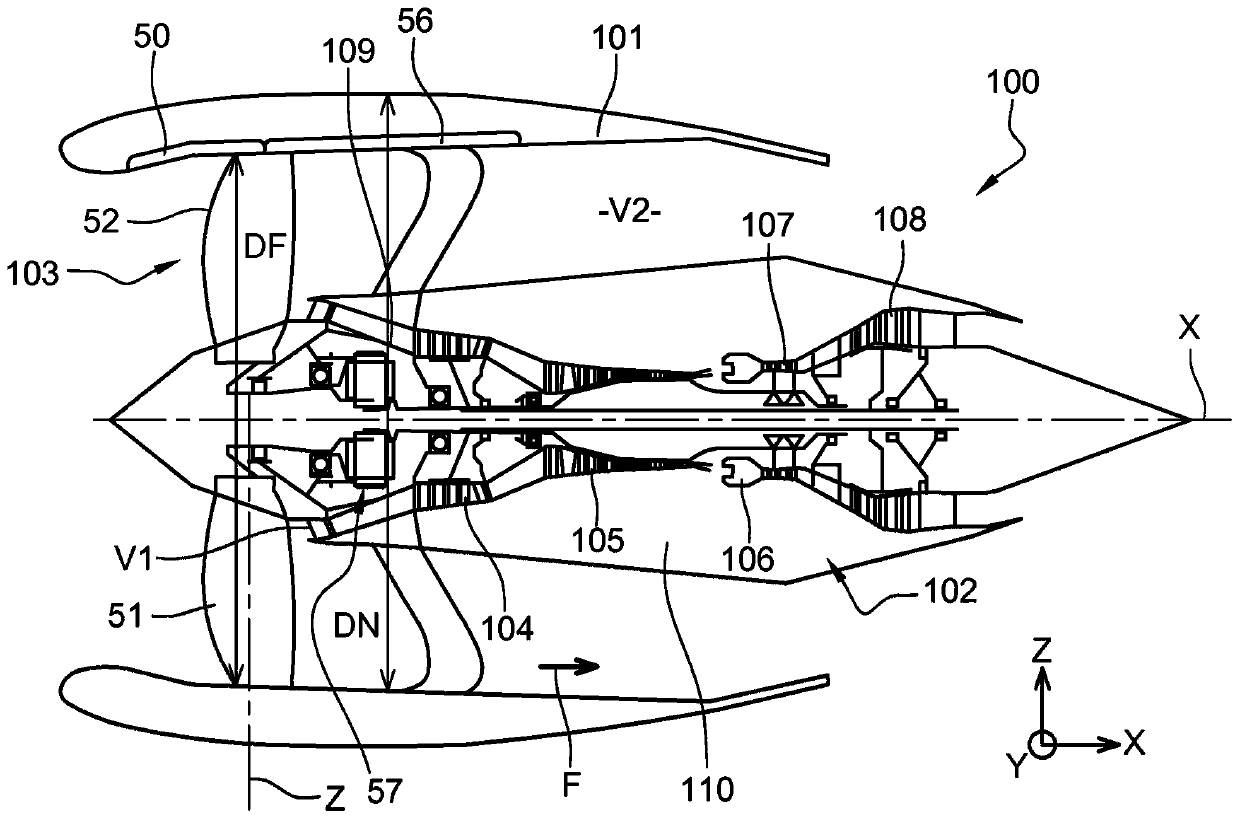

[0029] figure 1 An aircraft turbine 100 to which the invention is applicable is shown. The turbine 100 is here a ducted turbine extending along the longitudinal axis X. A ducted turbine generally comprises an external nacelle 101 surrounding a gas generator 102, upstream of which a fan 103 is mounted. In the present invention and in a general manner, the terms “upstream” and “downstream” are defined with respect to the flow of gas in the turbine 100 . The terms "upper" and "lower" are defined with respect to a radial axis Z perpendicular to the axis X and with respect to the distance from the longitudinal axis X. The transverse axis Y is also perpendicular to the longitudinal axis X and the radial axis Z. These axes X, Y, Z form an orthonormal symbol.

[0030] In this example, the gas generator 102 includes, from upstream to downstream, a low pressure compressor 104 , a high pressure compressor 105 , a combustion chamber 106 , a high pressure turbine 107 and a low pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com