Anti-ultraviolet heat-resistant natural raw lacquer film and preparation method thereof

An anti-ultraviolet and natural technology, applied in the field of coatings, can solve problems such as poor anti-ultraviolet resistance, and achieve the effects of simple operation, improved anti-ultraviolet performance and heat resistance, and excellent anti-ultraviolet performance and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Preparation of UV-resistant and heat-resistant natural lacquer film

[0044] Add 0.01 gram of artificially synthesized melanin particles to 9.99 grams of natural lacquer and place in a reactor, stir and mix evenly at room temperature;

[0045] The coating film has a thickness of 150 microns, and is dried at a high temperature of 120 degrees for 3 hours, then taken out, and then dried at room temperature for more than 7 days to obtain a natural raw lacquer film with UV resistance and heat resistance, which is recorded as D1.

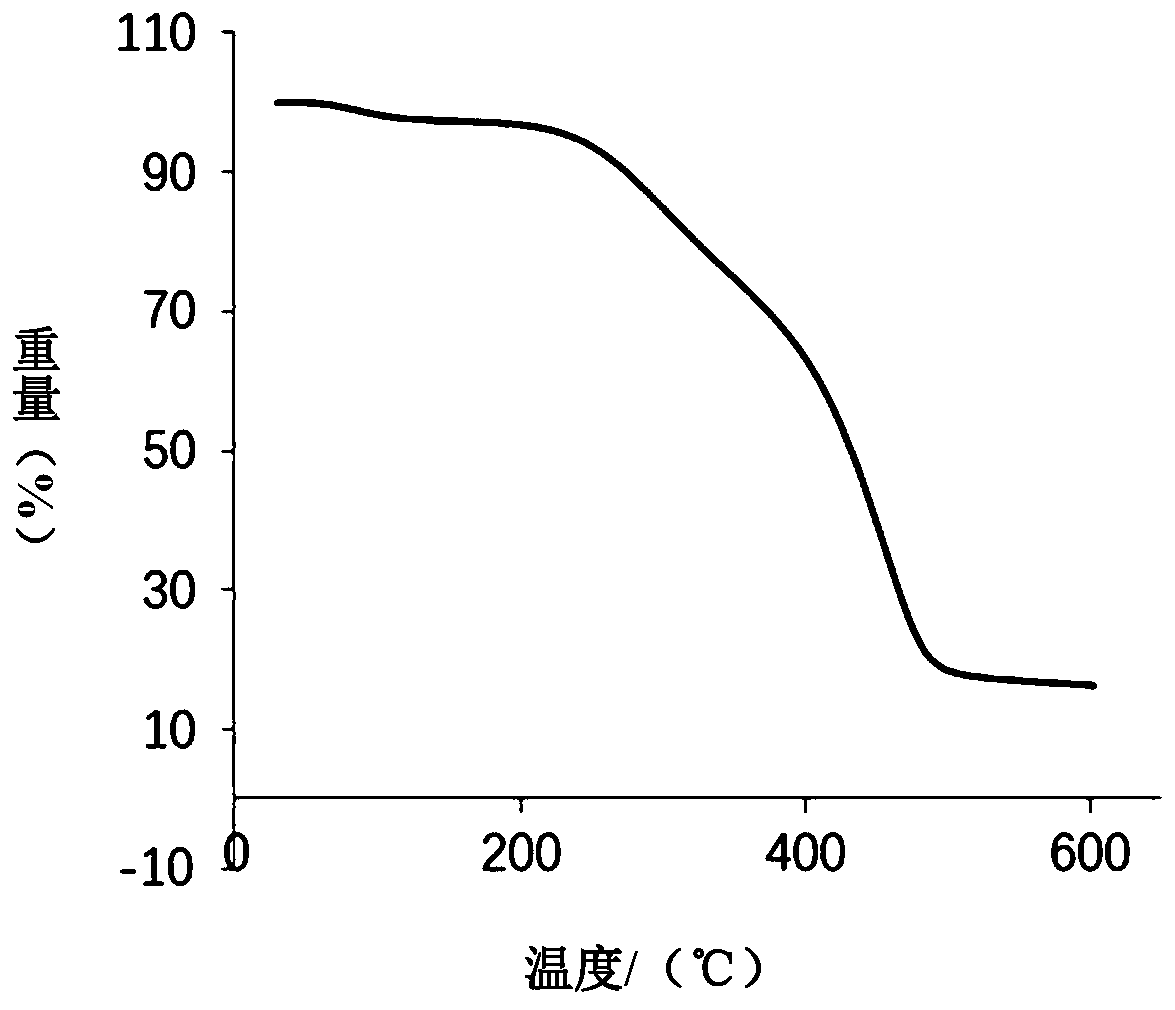

[0046] As a result of thermogravimetric analysis, the temperature for 50% weight loss is 439°C; the residual rate at 600°C is 17.4%.

Embodiment 2

[0047] Example 2 Preparation of UV-resistant and heat-resistant natural lacquer film

[0048] 0.2 grams of artificially synthesized melanin particles were added to 9.8 grams of natural lacquer and placed in a reactor, stirred and mixed evenly at room temperature;

[0049] The coating film has a thickness of 150 microns, and is dried at a high temperature of 120 degrees for 3 hours, then taken out, and then dried at room temperature for more than 7 days to obtain a UV-resistant and heat-resistant natural lacquer film, which is recorded as D2.

[0050] The result of thermogravimetric analysis is that the temperature at which the weight loss is 50% is 454°C; the residual rate at 600°C is 25.3%.

Embodiment 3

[0051] Example 3 Preparation of UV-resistant and heat-resistant natural lacquer film

[0052] 0.5 grams of artificially synthesized melanin particles are added to 9.5 grams of natural lacquer and placed in a reactor, stirred and mixed evenly at room temperature;

[0053] The coating film has a thickness of 150 microns, and is dried at a high temperature of 120 degrees for 3 hours, then taken out, and then dried at room temperature for more than 7 days to obtain a UV-resistant and heat-resistant natural lacquer film, which is recorded as D3.

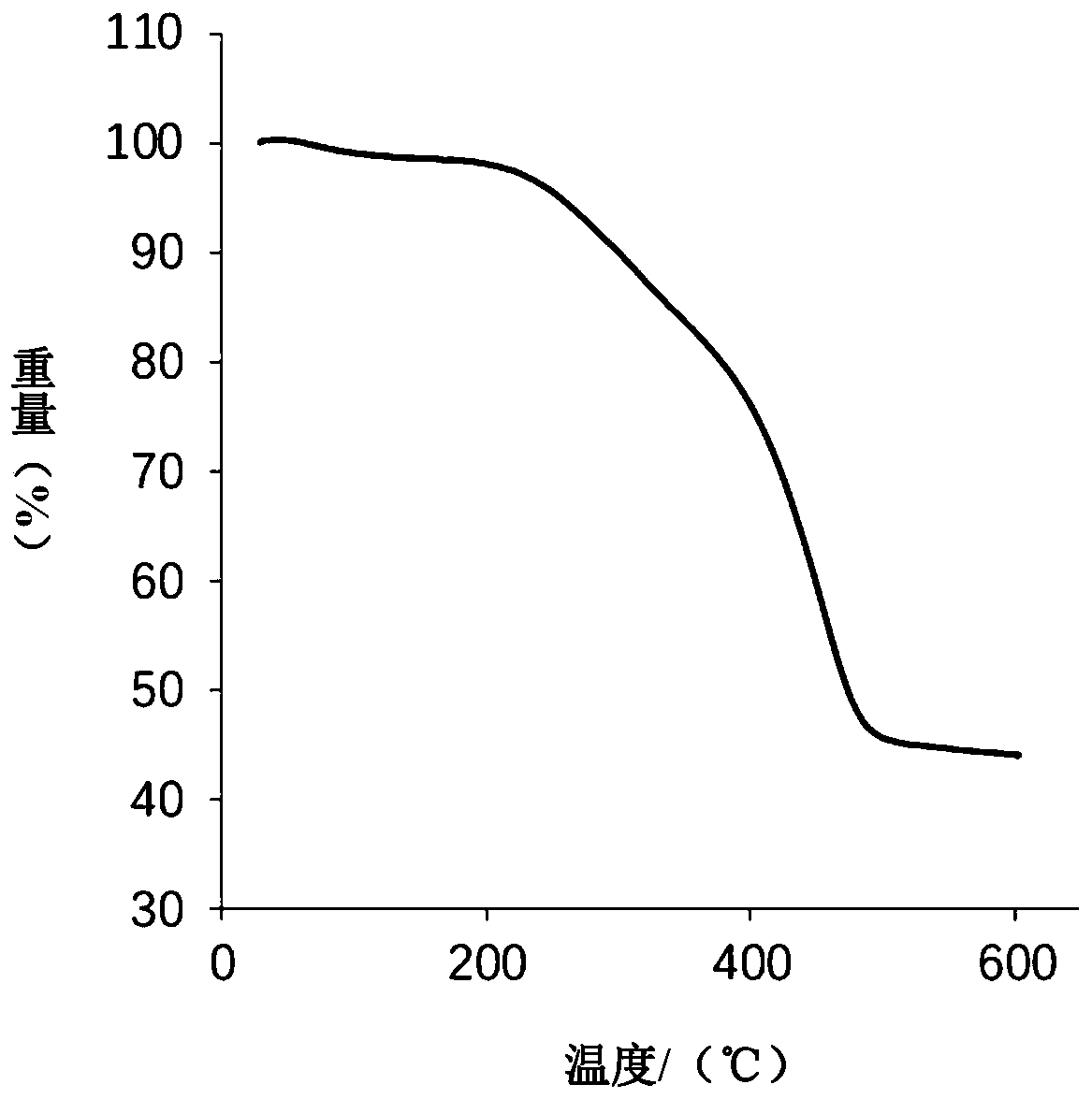

[0054] As a result of thermogravimetric analysis, the temperature for 50% weight loss is 458°C; the residual rate at 600°C is 43.9%, as figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com