Modified epoxy resin immobilized enzyme, and preparation method and application thereof

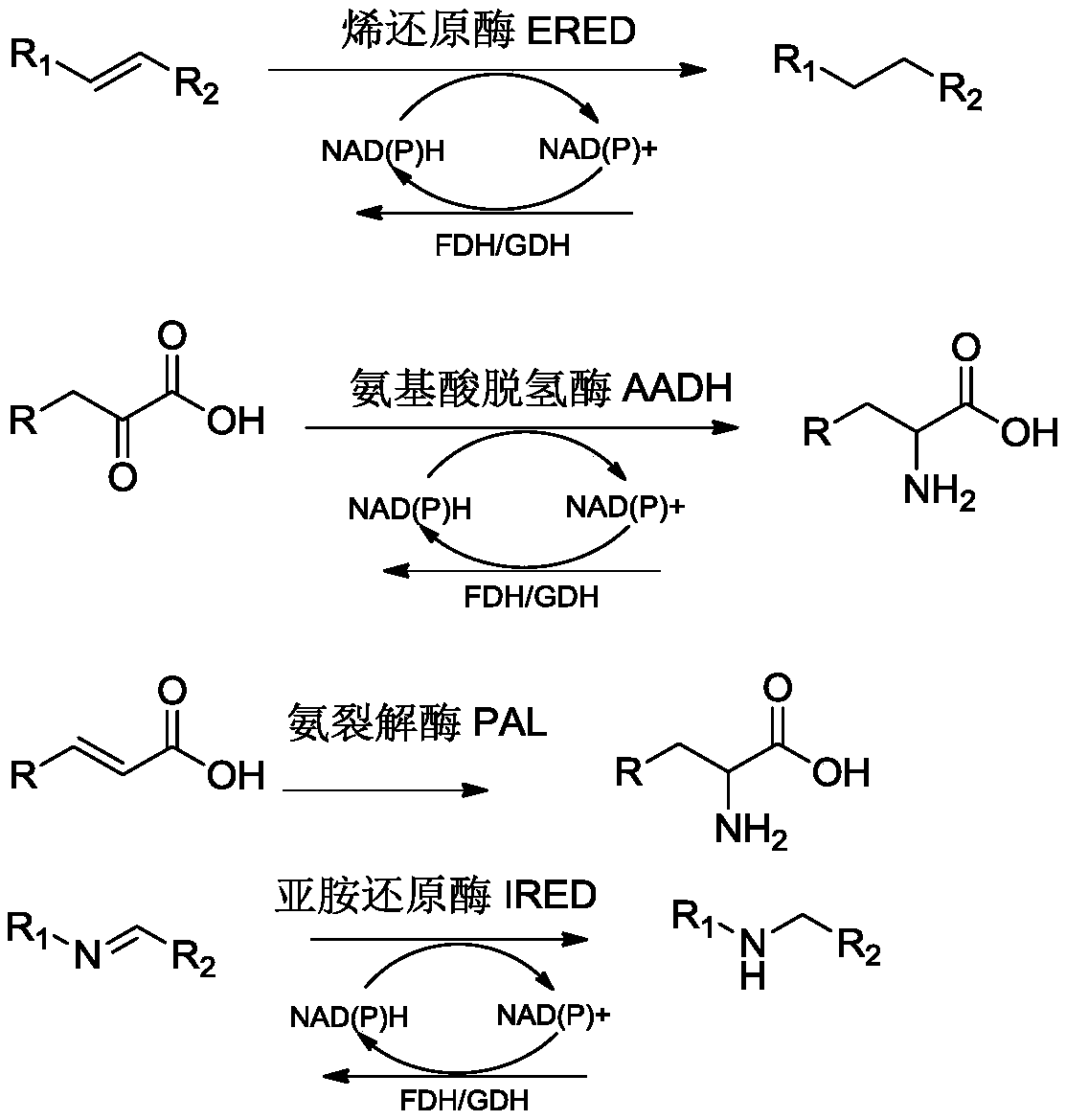

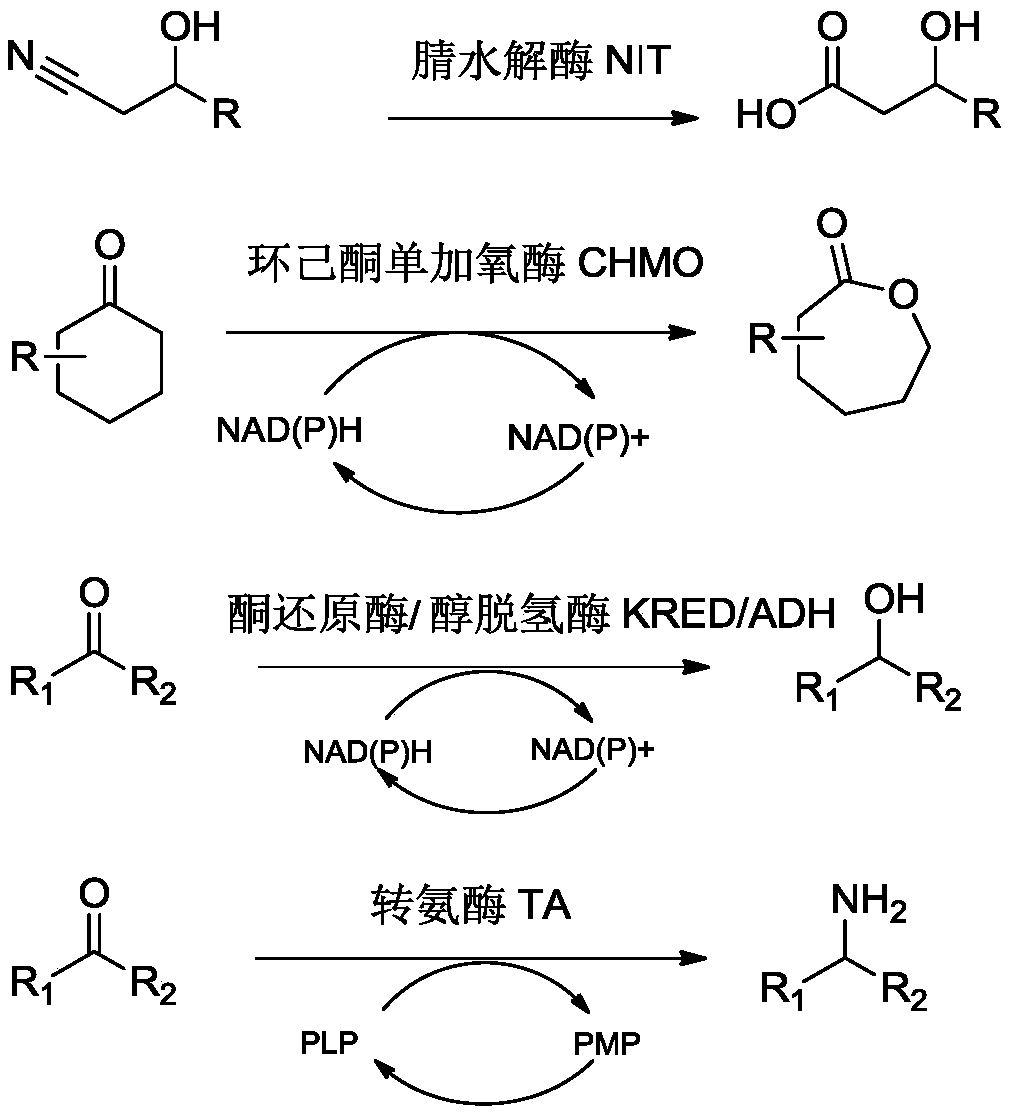

An epoxy resin, immobilized enzyme technology, applied in immobilized enzymes, biochemical equipment and methods, oxidoreductases, etc., can solve problems such as unsuitable enzyme application, and achieve the effect of reducing space inhibition and improving enzyme load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] According to a typical embodiment of the present invention, a preparation method of modified epoxy resin-immobilized enzyme is provided. The preparation method comprises the following steps: modifying the epoxy resin, adding polyethyleneimine to the modified epoxy resin for further modification, and then adding the enzyme to be immobilized and glutaraldehyde for immobilization to obtain the immobilized epoxy resin Catase.

[0043] Applying the technical scheme of the present invention, the epoxy resin is modified, and polyethyleneimine is added to the modified epoxy resin for further modification, and the aldehyde group in the resin is covalently bonded to the amino group in the polyethyleneimine. The enzyme is then activated by the bifunctional reagent glutaraldehyde, in this way, the steric resin arms are increased to form a network structure, and the enzyme can be more easily bound by covalent binding, because the steric inhibition is reduced, and the enzyme loading ...

Embodiment 1

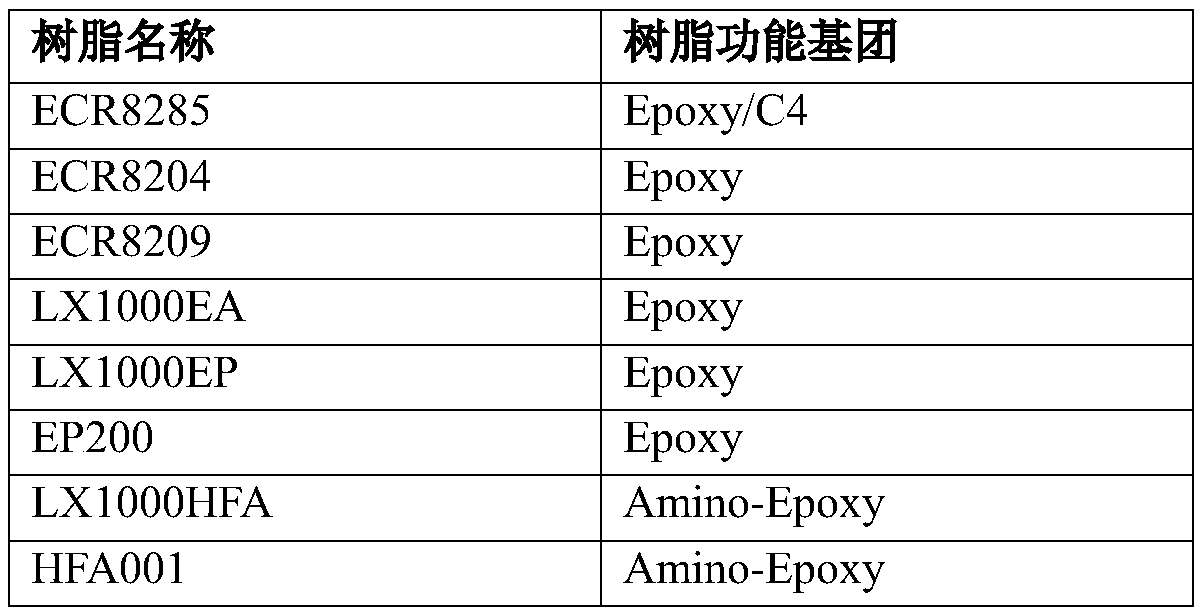

[0088] Immobilization of Enzyme on Sodium Periodate Oxidized Epoxy Resin

[0089] Add 5 g of epoxy resin ECR8285 or LX1000EP into 20 mL of 1M acetic acid, stir gently at room temperature for 12 hours, wash the acetic acid-treated carrier with 20 mL of distilled water for 3 times, and suspend the treated carrier in 20 ml of 50 mM sodium periodate , stirred gently at room temperature for 2 h, filtered and washed with distilled water.

[0090] 5g modified epoxy resin was resuspended with 0.1M phosphate buffer, added PEI, the final concentration was 1%, adjusted the pH to pH7.0, after gentle stirring for 2 hours, added 50-100mM glutaraldehyde, at room temperature Stir for 1-2 hours. The carrier resin was then filtered and washed with 10 ml of water. The washed carrier was added to the enzyme solution (10ml enzyme, containing 5mg / mL cofactor, dissolved in 40mL 100mM phosphate buffer, pH7.0), stirred at 10-25°C for 4 hours, and kept in the refrigerator overnight. After standing o...

Embodiment 2

[0092] Immobilization of Enzyme on Sodium Periodate Oxidized Epoxy Resin

[0093] Add 5 g of epoxy resin beads into 50 mL of 1 M acetic acid, under gentle stirring at room temperature for 12 h, wash the acetic acid-treated support with 50 mL of distilled water for 3 times with gentle stirring for 10 min each time, suspend the treated support in 100 ml sodium iodate, stirred gently at room temperature for 2 hours, filtered and washed with distilled water.

[0094] 5 g of modified epoxy resin was resuspended with 0.1 M phosphate buffer, PEI was added to a final concentration of 1%, the pH was adjusted to pH 7.0, and stirred gently for 2 hours. The carrier was then filtered and washed with 10 ml of water. The washed carrier was added to the enzyme solution (10ml enzyme, containing 5mg / mL cofactor, dissolved in 40mL 100mM phosphate buffer, pH7.0), stirred at room temperature for 4 hours, and kept in the refrigerator overnight. After standing overnight, 20-100 mM glutaraldehyde w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com