Full-process automatic solid-liquid separation and drying system for dye intermediate

A technology for dye intermediates and solid-liquid separation, which is applied in the field of solid-liquid separation and drying systems for dye intermediates, can solve problems such as failure to meet environmental protection requirements, inability to increase output, and difficulty in collecting exhaust gas, achieving low labor intensity for workers, The effect of using less equipment and less manual use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

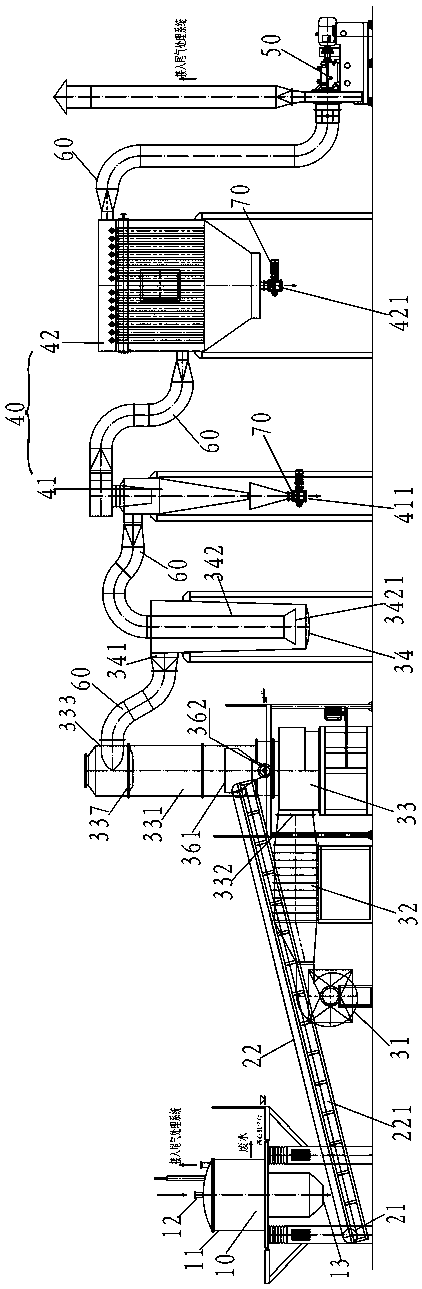

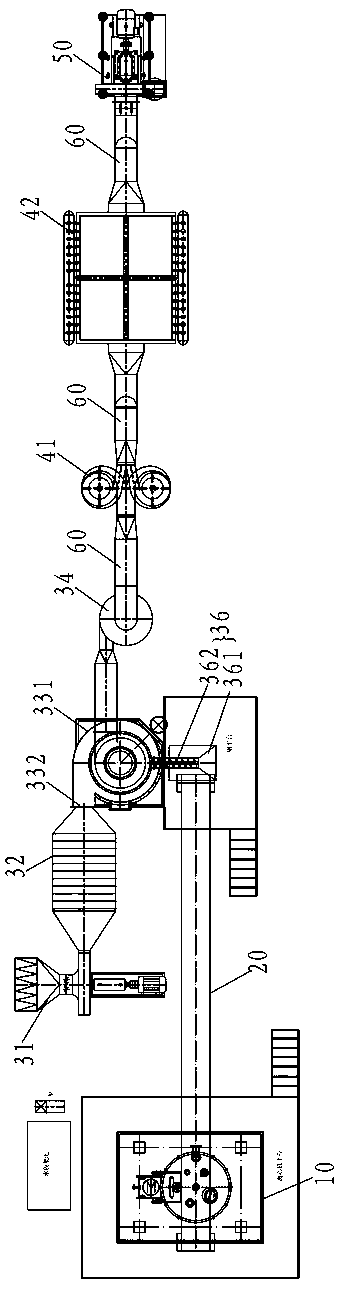

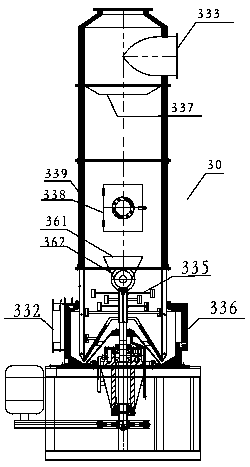

[0040] to combine figure 1 As shown, it is a fully automated solid-liquid separation and drying system 100 for dye intermediates in a preferred embodiment of the present invention, which includes: a fully automatic discharge centrifuge 10, an automatic material conveyor 20, a spin flash evaporation Drying device 30 , dust collector 40 , induced draft fan 50 and pipeline 60 .

[0041] The fully automatic bottom discharge centrifuge 10 includes a casing 11 with a feed pipe 12 on the top of the casing 11, a centrifugal drum inside the casing, and a filter cloth on the centrifugal drum. There is also an automatic scraper inside the casing, which can scrape off the material on the centrifugal drum and drop it to the discharge port 13 at the bottom of the casing. The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap