End concentricity assembling and adjusting mechanism and adjusting method thereof

A technology for adjusting mechanism and concentricity, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as high concentricity requirements, inability to accurately locate, time-consuming and labor-intensive, etc., to improve production efficiency, reduce production costs, adjust convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

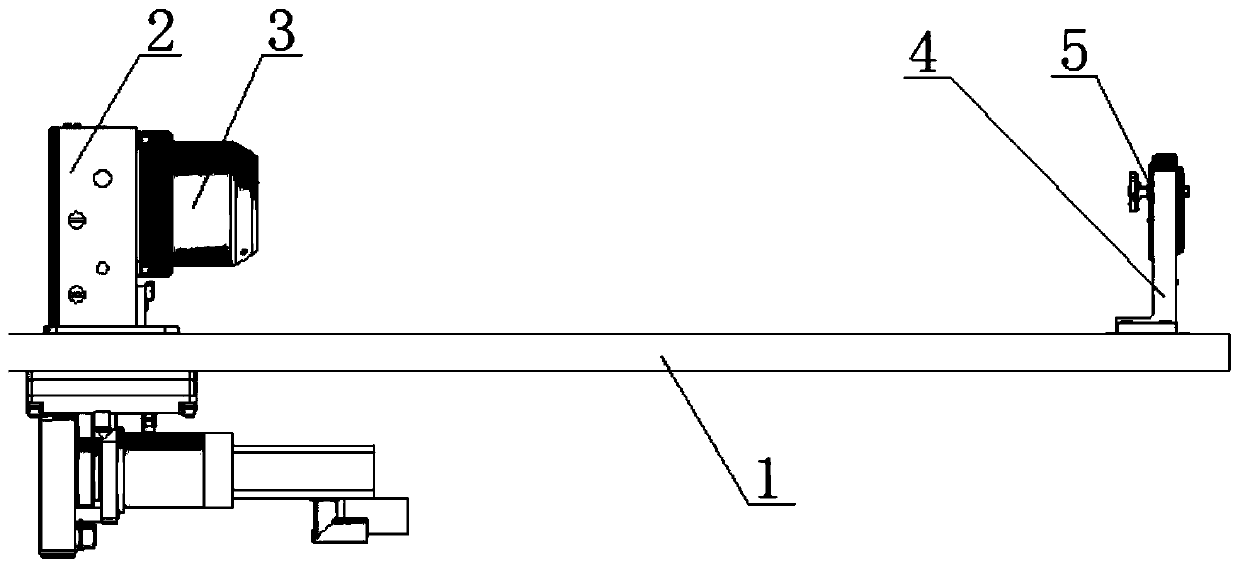

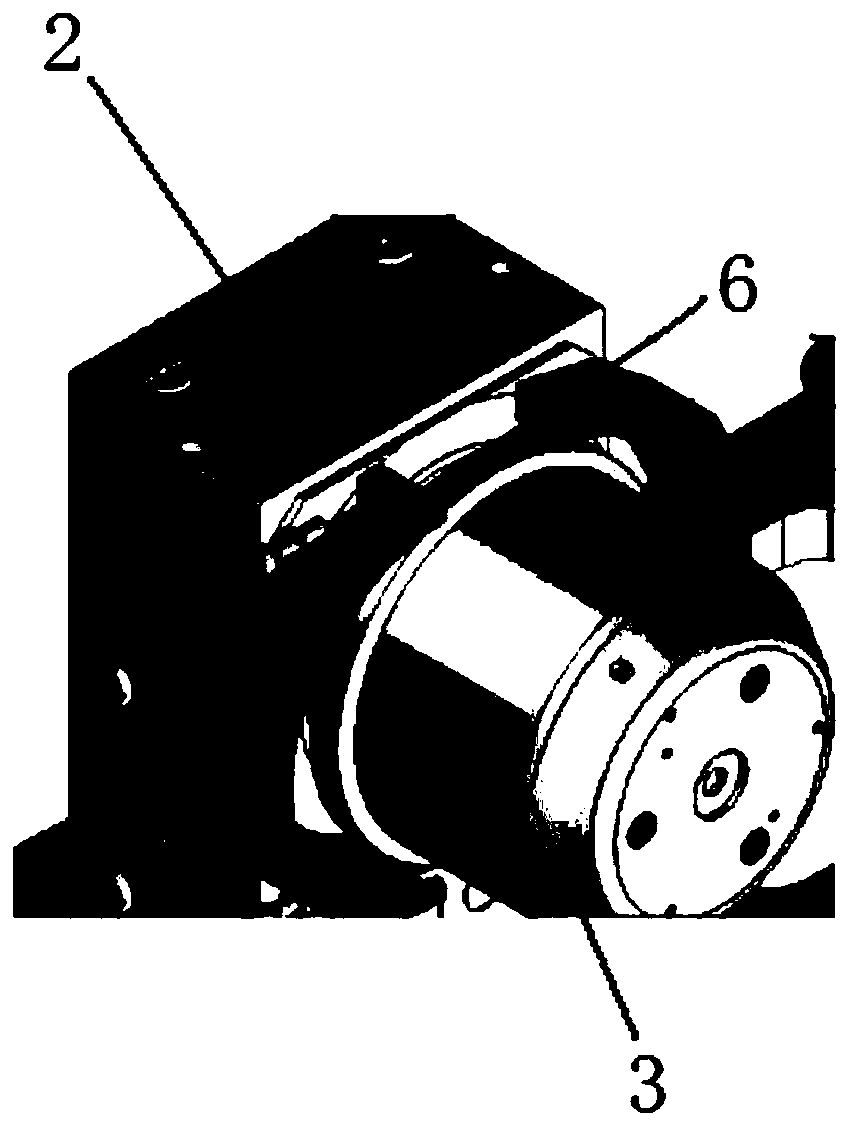

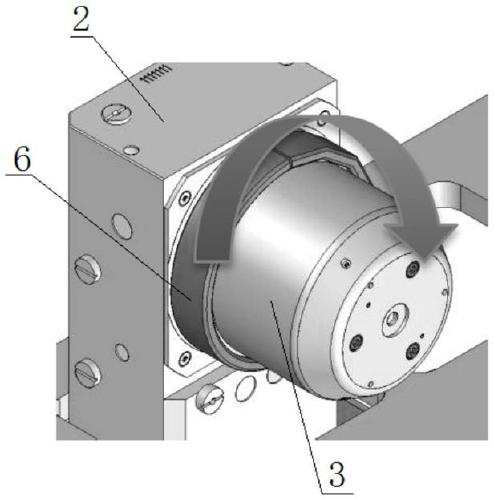

[0030] see Figure 1-10 , a terminal concentricity assembly adjustment mechanism related to the present invention includes a base 1, a terminal 2, a laser emitting device 3, a support frame 4, a target plate 5 and a clamp 6; the top surface of the base 1 is provided with a terminal The head 2 and the support frame 4, the end head 2 and the support frame 4 are arranged opposite and on the same straight line, the target is assembled between the end head 2 and the support frame 4; the laser emitting device 3 is fixedly connected by a clamp 6 On the end 2, the target disk 5 is arranged on the support frame 4, the above-mentioned laser emitting device 3 is arranged opposite to the target disk 5, and the laser spot emitted by the laser emitting device 3 falls on the target disk 5;

[0031] The laser emitting device 3 includes a housing 3.1, the housing 3.1 has a bowl-shaped structure, and a flange is provided at the edge of the outer wall of the opening end of the housing 3.1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com