Hardware-in-the-loop test system for whole vehicle controller of four-wheel distributed drive electric bus

A vehicle controller and electric bus technology, applied in the general control system, control/adjustment system, test/monitoring control system, etc., can solve the problems of high cost, prone to safety accidents, high development cost, etc., to reduce development cost , reduce security risks, and save development time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

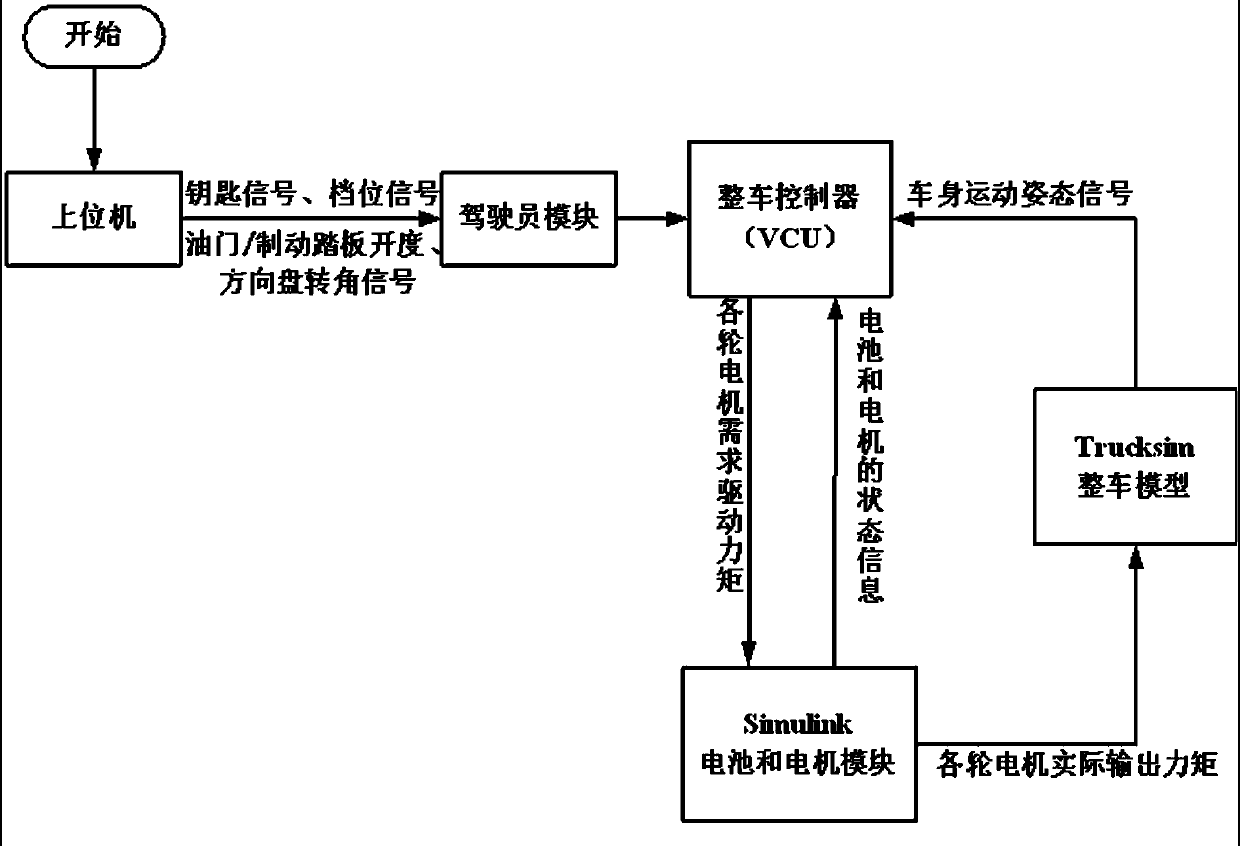

[0031] The specific implementation manners of the present invention will be further described below with reference to the accompanying drawings.

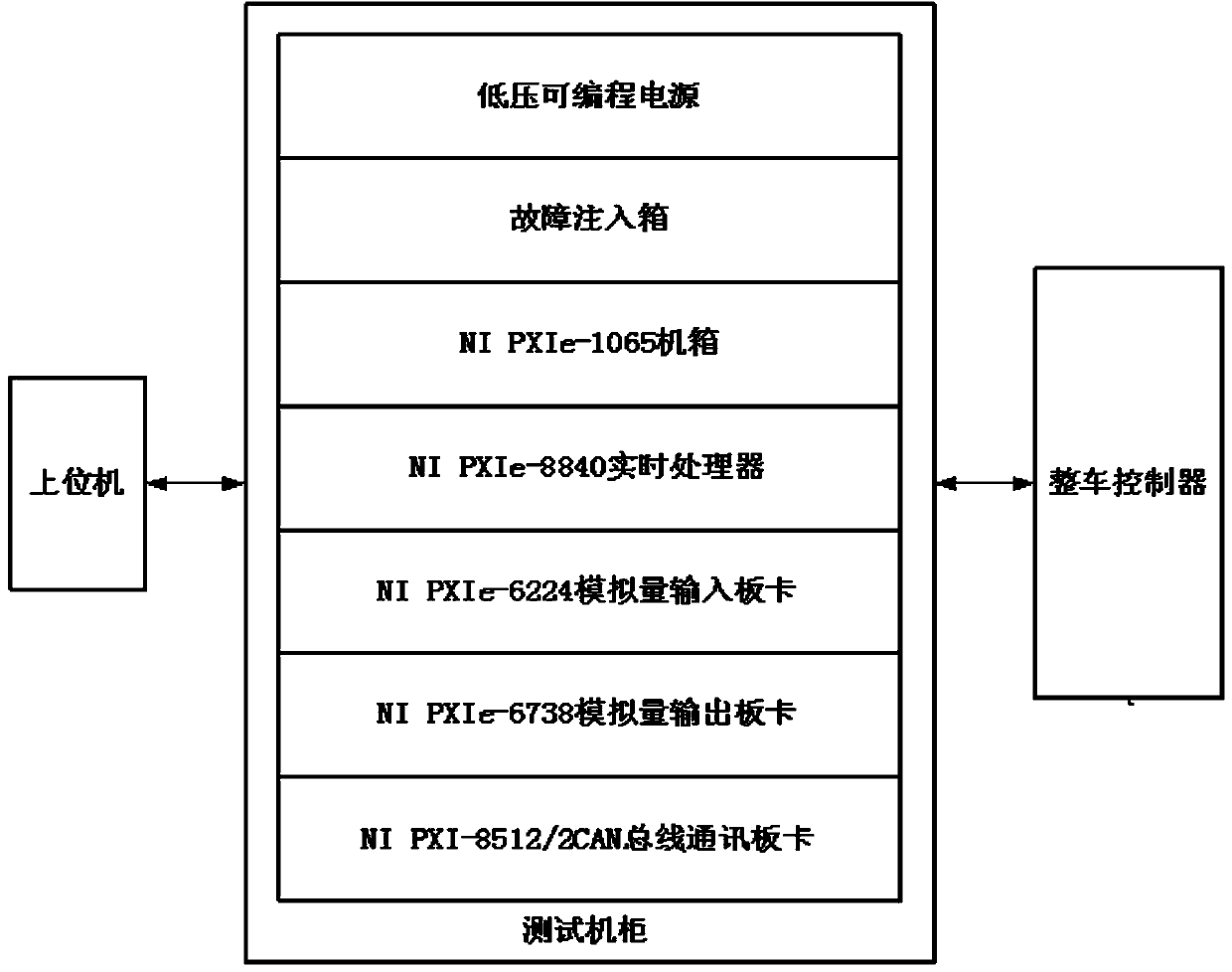

[0032] like figure 1 and figure 2 As shown, a hardware-in-the-loop test system for the controller of a four-wheel distributed drive electric bus: firstly, the hardware platform of the hardware-in-the-loop system is built. The test system is built based on the NI-PXI platform. The main components include: computer, PXI chassis, real-time processor, analog input / output board, CAN communication board, programmable power supply, fault injection module and signal processing module.

[0033]The PXI chassis uses the NI PXIe-1065 chassis, and the boards and processors used include:

[0034] (1) Real-time processor NI PXIe-8840, used to run the vehicle model and simulate the vehicle running state;

[0035] (2) The analog input board NI PXIe-6224 is used to collect the analog output signal of the VCU;

[0036] (3) The analog output board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com