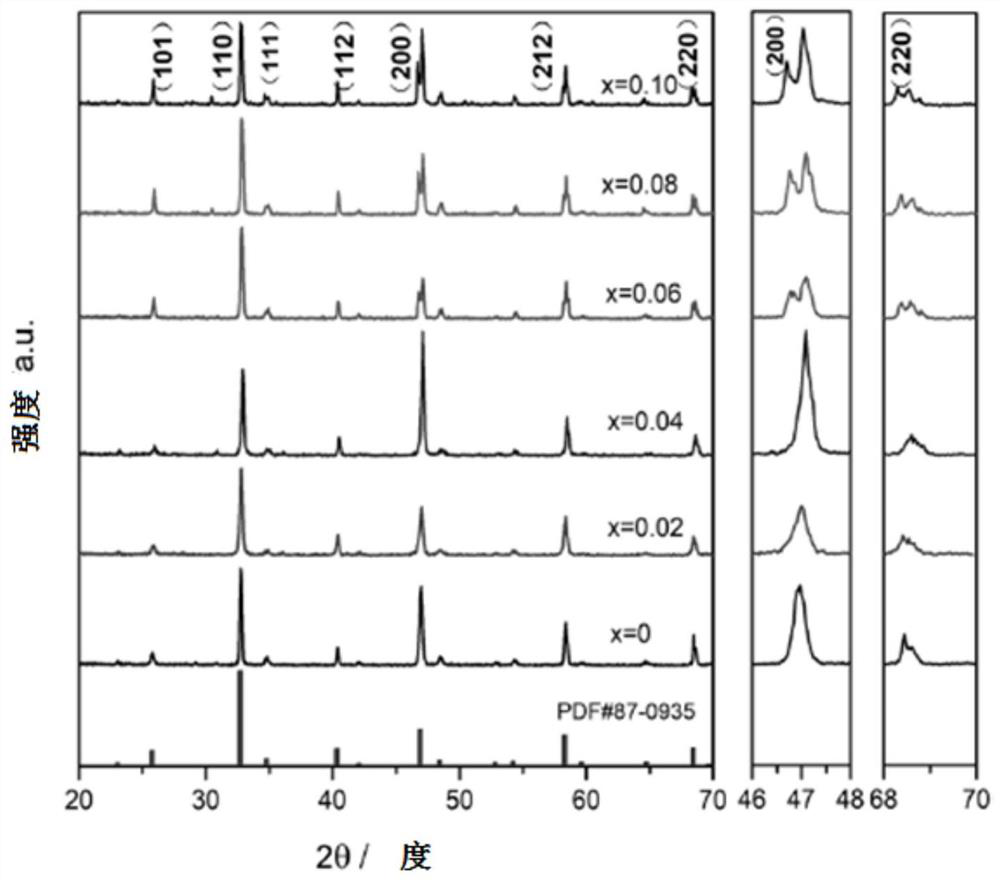

A kind of silver-silver germanium doped perovskite-type solid electrolyte and preparation method thereof

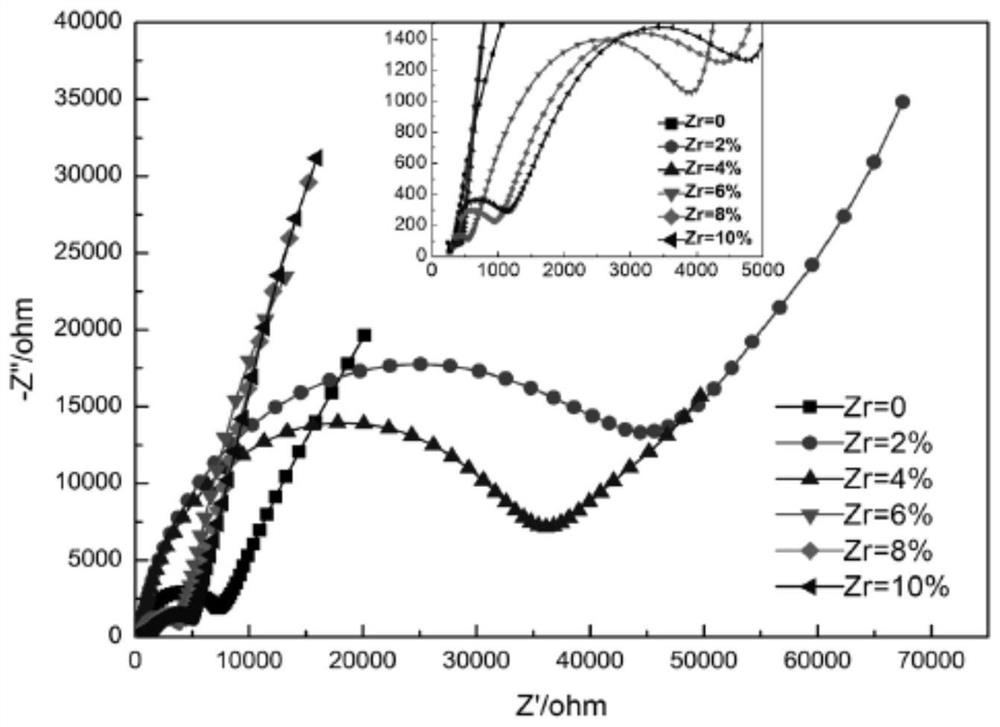

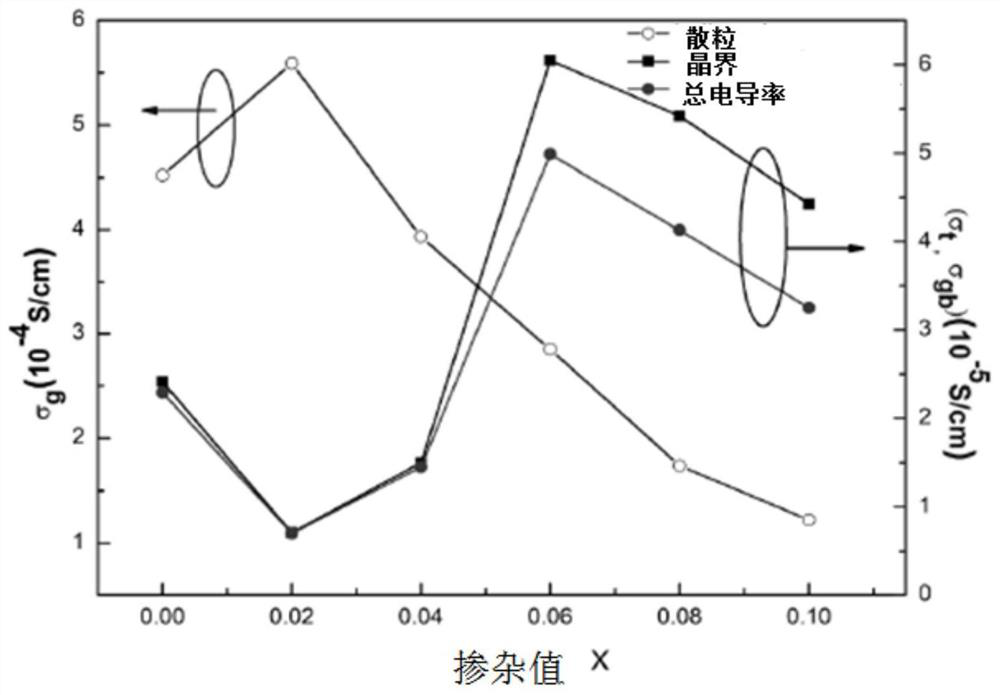

A solid electrolyte, perovskite-type technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve problems such as being unable to meet actual needs, and the conductivity of grain boundaries is only 10-5S/cm, to overcome Effect of grain boundary instability, performance improvement, and uniformity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the second aspect of the present invention provides a preparation method of arginite-doped perovskite-type solid electrolyte material, comprising the following steps:

[0037] (1) According to the chemical formula Li0.33La0.57(Ti(1-x), Ag9GeSe6-x-y Tey)O 3 , 0≤x≤0.1, 0≤y≤0.75 and x, y are not 0 at the same time, respectively weigh lithium hydroxide monohydrate, lanthanum oxide, titanium dioxide, Ag element, Ge element, Se element, Te element in proportion as ingredients;

[0038] (2) ball milling is carried out after the ingredients are mixed;

[0039] (3) pre-sintering the powder obtained by ball milling to obtain a precursor with a crystal structure;

[0040] (4) carrying out the second ball milling to the pre-sintered precursor to obtain fine particles, and pressing the particles into tablets;

[0041] (5) degumming the tablet;

[0042] (6) sintering the pressed sheet after debinding to obtain the perovskite-type solid electrolyte material doped...

Embodiment 1

[0061] Example 1 (doping with arginite):

[0062] According to the chemical formula Li0.33La0.57(Ti(1-x), Ag9GeSe6-x-y Tey)O 3 (0≤x≤0.1, 0≤y≤0.75 and x, y are not 0 at the same time) (where x=0.02, y=0.5) The molar ratios were weighed respectively lithium hydroxide monohydrate, lanthanum oxide, titanium dioxide, Ag element, Ge elemental substance, Se elemental substance, Te elemental compound are prepared and vacuum-packed. Using absolute ethanol as a medium, the mixture was added to a ball milling jar for ball milling for 6-12 hours, and the ball-milled slurry was dried and then put into a crucible for calcination at 1100° C. for 6-12 hours. After the pre-sintering is completed, the obtained powder is subjected to secondary ball milling for 6-12 hours, then the powder after secondary ball milling is dried and placed in a mortar, 6% polyvinyl alcohol is added, and fine particles are obtained by fully grinding. The good granules were placed on a tableting machine for tabletin...

Embodiment 2

[0063] Example 2 (doping with arginite):

[0064] According to the chemical formula Li0.33La0.57(Ti(1-x), Ag9GeSe6-x-y Tey)O 3 (0≤x≤0.1, 0≤y≤0.75 and x, y are not 0 at the same time) (where x=0.04, y=0.5) The molar ratios were weighed respectively lithium hydroxide monohydrate, lanthanum oxide, titanium dioxide, Ag element, Ge elemental substance, Se elemental substance, Te elemental compound are prepared and vacuum-packed. Using absolute ethanol as a medium, the mixture was added to a ball milling jar for ball milling for 6-12 hours, and the ball-milled slurry was dried and then put into a crucible for calcination at 1100° C. for 6-12 hours. After the pre-sintering is completed, the obtained powder is subjected to secondary ball milling for 6-12 hours, then the powder after secondary ball milling is dried and placed in a mortar, 6% polyvinyl alcohol is added, and fine particles are obtained by fully grinding. The good granules were placed on a tableting machine for tabletin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com