Preparation method of fluorinated polyhexamethylene biguanide

A technology of fluorinated polyhexamethylene biguanide and polyhexamethylene biguanide hydrochloride, which is applied in the field of preparation of fluorinated polyhexamethylene biguanide, can solve the problems of harming the health of the whole body, fluorine-resistant strains, and excessive fluoride intake and other issues to achieve the effect of avoiding side effects, reducing side effects, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

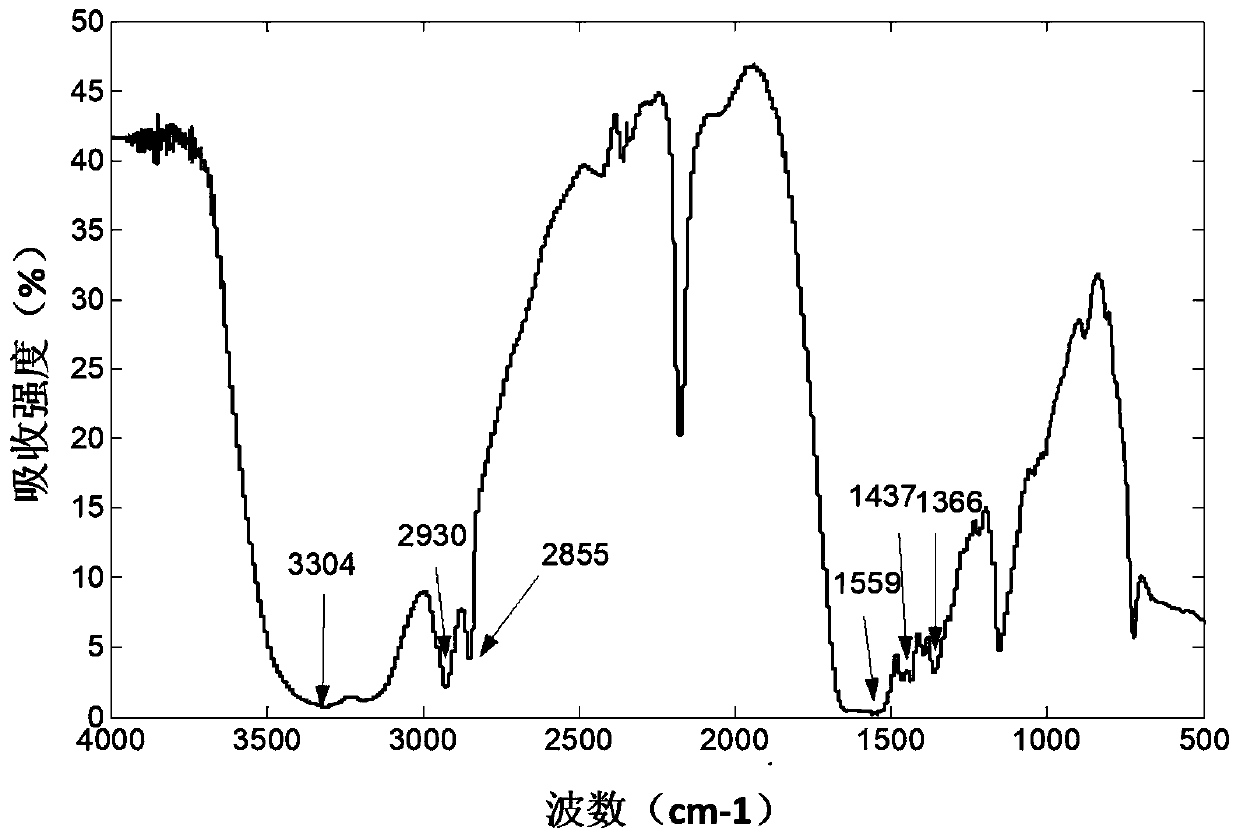

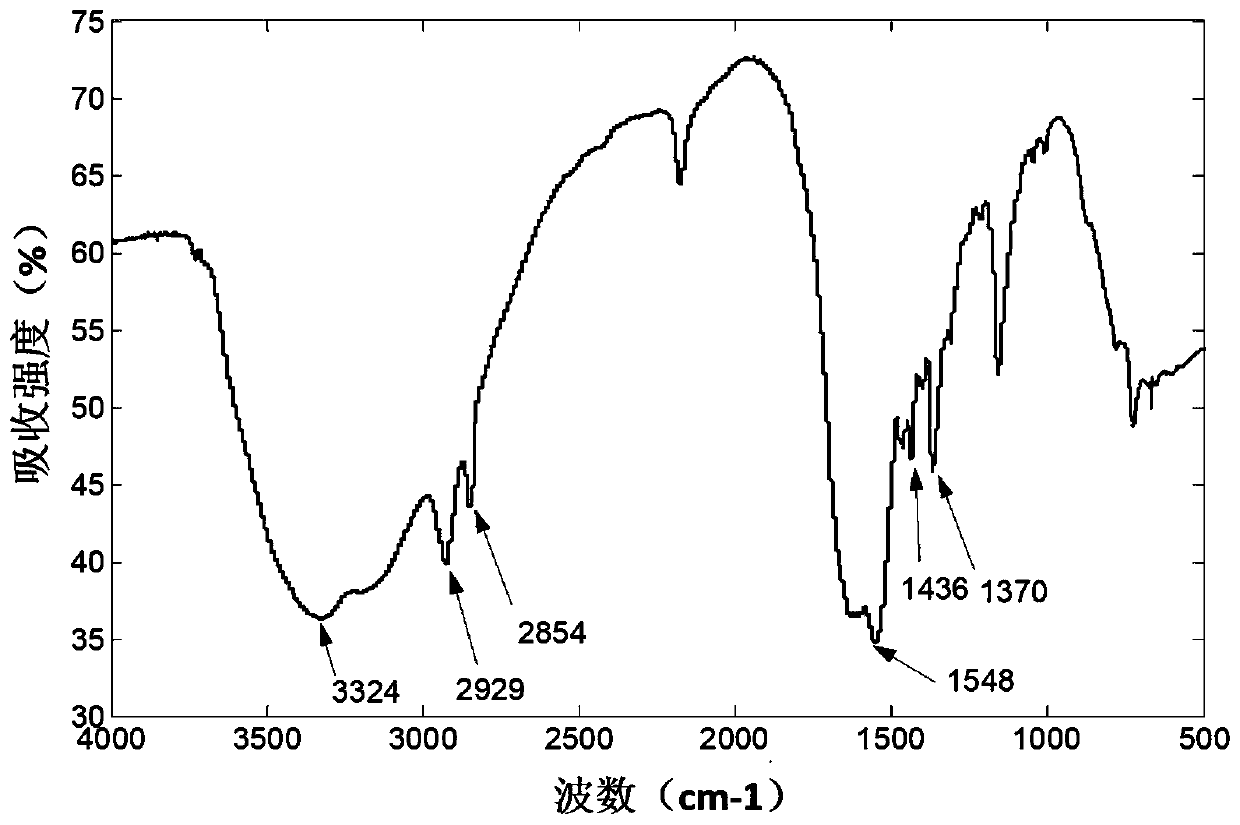

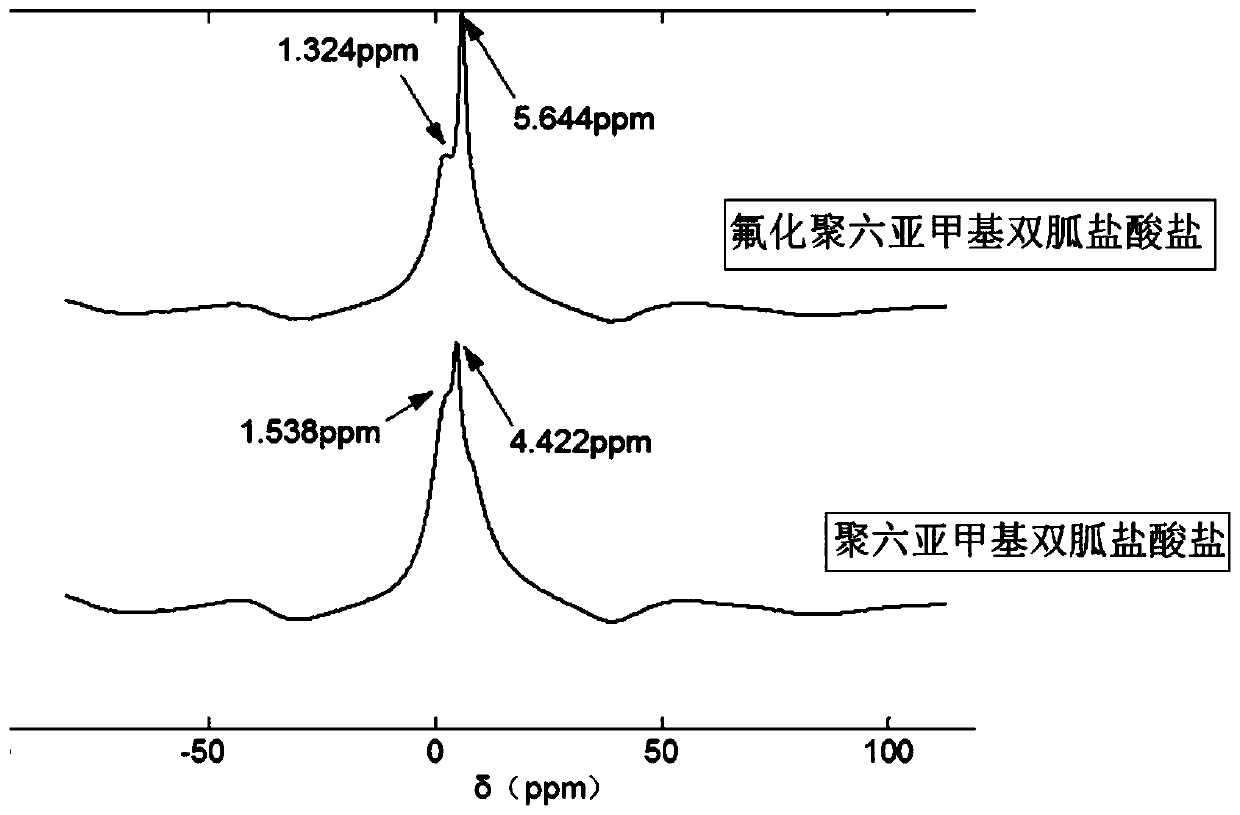

[0028] The polyhexamethylene biguanide hydrochloride powder (n=3) was dissolved in ultrapure water, and oscillated with a vortex oscillator until dissolved. Dissolve the silver fluoride powder in ultrapure water and vibrate with a vortex until dissolved. Add the high-concentration silver fluoride solution drop by drop into the polyhexamethylene biguanide hydrochloride solution, and a white flocculent precipitate will be formed after the addition, and continue to drop until the excess silver fluoride no longer produces new precipitates. Divide the obtained solution into 1.5mL centrifuge tubes, put them into a centrifuge, 12000rpm, 30min, carefully draw the supernatant into a new centrifuge tube, put it into the centrifuge again and repeat centrifugation until no precipitation occurs . Put the dialysis bag containing the sample into a glass beaker, add 2L of ultrapure water, place it on a magnetic stirrer for dialysis, and the ratio of the dialysis sample to the dialysate is 1:...

Embodiment 2

[0030] The polyhexamethylene biguanide hydrochloride powder (n=45) was dissolved in ultrapure water, oscillated with a vortex oscillator until dissolved and set aside. Dissolve the silver fluoride powder in ultrapure water and vibrate with a vortex until dissolved. Add the high-concentration silver fluoride solution drop by drop into the polyhexamethylene biguanide hydrochloride solution, and a white flocculent precipitate will be formed after the addition, and continue to drop until the excess silver fluoride no longer produces new precipitates. Divide the obtained solution into 1.5mL centrifuge tubes, put them into a centrifuge, 12000rpm, 30min, carefully draw the supernatant into a new centrifuge tube, put it into the centrifuge again and repeat centrifugation until no precipitation occurs . Put the dialysis bag containing the sample into a glass beaker, add 2L of ultrapure water, place it on a magnetic stirrer for dialysis, and the ratio of the dialysis sample to the dial...

Embodiment 3

[0032] The polyhexamethylene biguanide hydrochloride powder (n=4) was dissolved in ultrapure water, oscillated with a vortex oscillator until dissolved and set aside. Dissolve the silver fluoride powder in ultrapure water and vibrate with a vortex until dissolved. Add the high-concentration silver fluoride solution drop by drop into the polyhexamethylene biguanide hydrochloride solution, and a white flocculent precipitate will be formed after the addition, and continue to drop until the excess silver fluoride no longer produces new precipitates. Divide the obtained solution into 1.5mL centrifuge tubes, put them into a centrifuge, 12000rpm, 30min, carefully draw the supernatant into a new centrifuge tube, put it into the centrifuge again and repeat centrifugation until no precipitation occurs . Put the dialysis bag containing the sample into a glass beaker, add 2L of ultrapure water, place it on a magnetic stirrer for dialysis, and the ratio of the dialysis sample to the dialy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com