Fermentation culture method of aspergillus producing beta-cyclodextrin glucosyltransferase

A fermentation culture, glucose-based technology, applied in the field of microorganisms, can solve the problems of poor fermentation ability of bacillus, poor enzyme production performance, food contamination and miscellaneous bacteria, etc., and achieve the effect of low cost, short fermentation time and improved enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] 1 materials and methods

[0055] 1.1 Materials and instruments

[0056] 1.1.1 Sample

[0057] Qiao Wife Doubanjiang

[0058] 1.1.2 Types of media

[0059] 1. Primary screening medium: 3.0g beef extract, 5.0g peptone, 2.5g glucose, 20g agar and dilute to 1L with water, and sterilize at 121°C for 20min.

[0060] 2. Re-screening medium / L: soluble starch 10g, peptone 5g, yeast extract 5g, K 2 HPO 4 0.2g, MgSO 4 .7H 2 O0.2g, NaCO 3 0.2g, 0.3g phenolphthalein, 0.1g methyl orange, 20g agar, sterilized at 121°C for 20min.

[0061] 3. Basic fermentation medium / L (same as seed medium): yeast powder 10g / L, peptone 20g, glucose 20g, K 2 HPO 4 1g, MgSO 4 .7H 2 O 0.5g, natural pH, aliquot into 250ml conical flasks, 50ml per bottle, sterilize at 121°C for 20min.

[0062] 1.1.2 Reagents

[0063] 1.1.3 Apparatus and equipment

[0064] 1.2 Strain screening

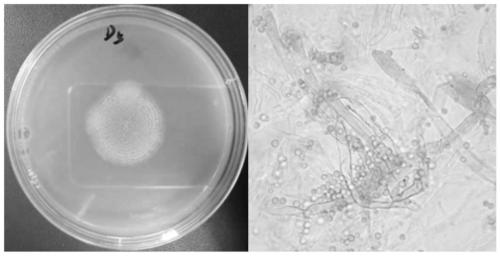

[0065] 1.2.1 Screening, separation and purification of strains

[0066] Under aseptic conditions, weigh 10g of bean paste sample and place it in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com