Flexible circuit board and loudspeaker

A flexible circuit board and conductive layer technology, applied in the field of acoustics, can solve the problems of difficulty in passing the reliability test, fatigue cracks in the copper layer, large stress in the copper layer, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

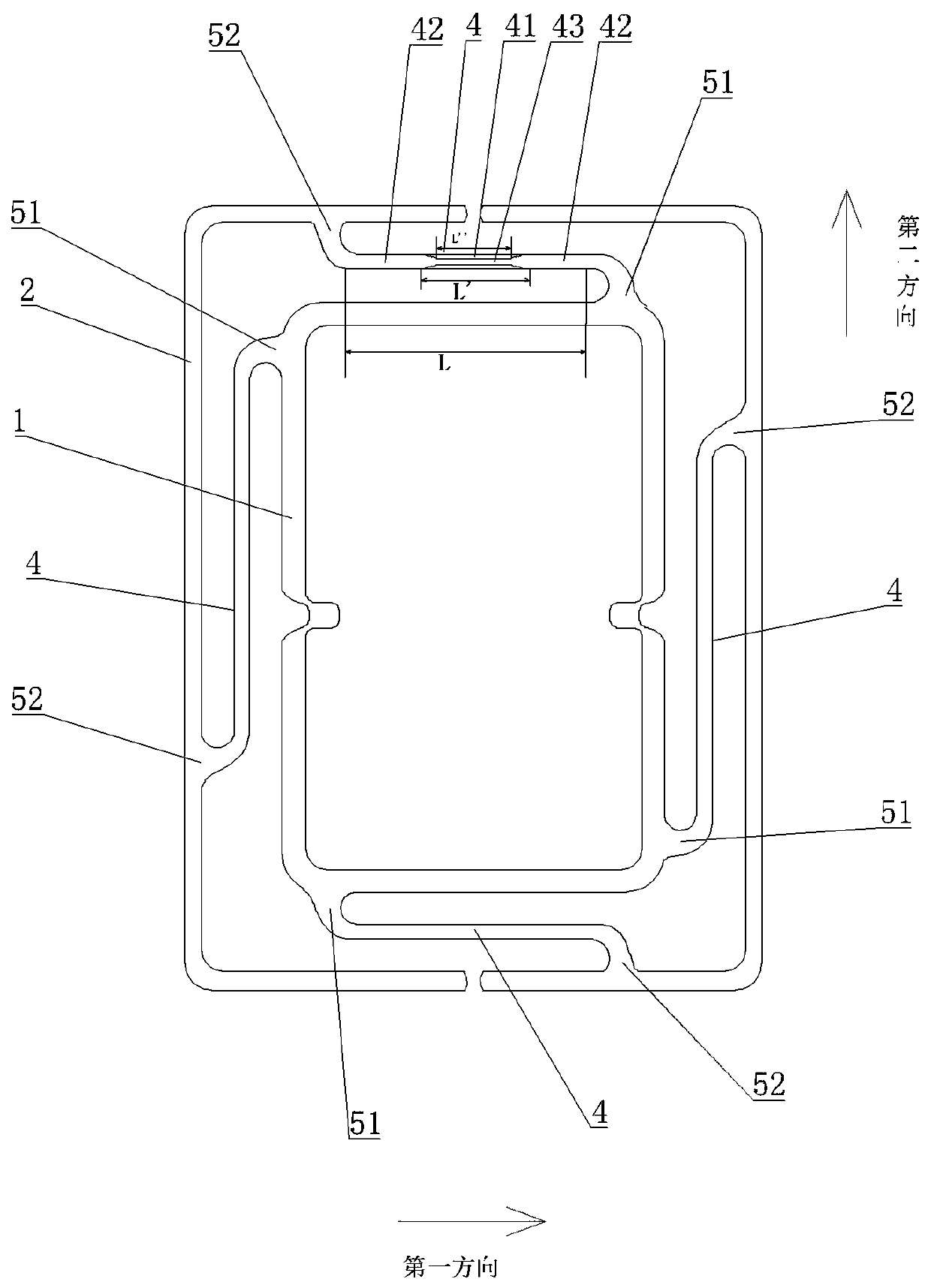

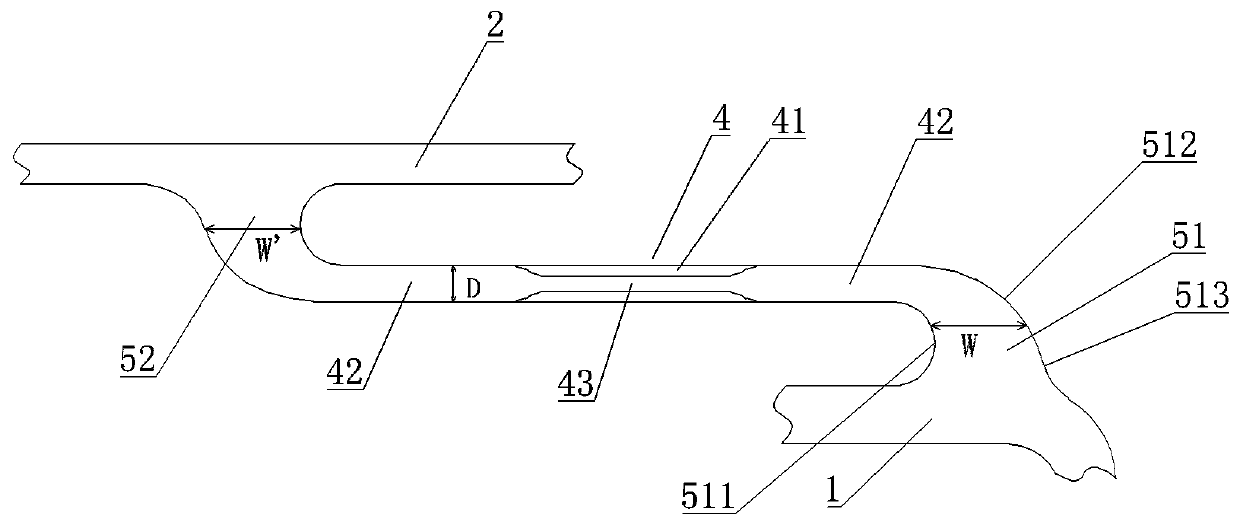

[0038] Embodiment 1: as figure 1 As shown, a flexible circuit board is a multilayer structure composed of multiple material layers or a multilayer structure composed of multiple material layers and glue layers; the material layer includes a conductive layer in the central area and a The insulating layer located on the outer surface, in this implementation, the conductive layer is a copper layer, not limited to the copper layer, it can also be constantan alloy, gold, etc.; the flexible circuit board includes the vibration part 1 fixed with the voice coil and the frame Fixed fixed part 2, the vibration part 1 and the fixed part 2 are connected by a cantilever, and the cantilever includes a cantilever body 4 and roots located at both ends of the cantilever body, and the cantilever body is respectively connected to the vibration part through the two roots. 1 is connected to the fixed part 2, the cantilever body 4 includes the second cantilever section 42 located at both ends and t...

Embodiment 2

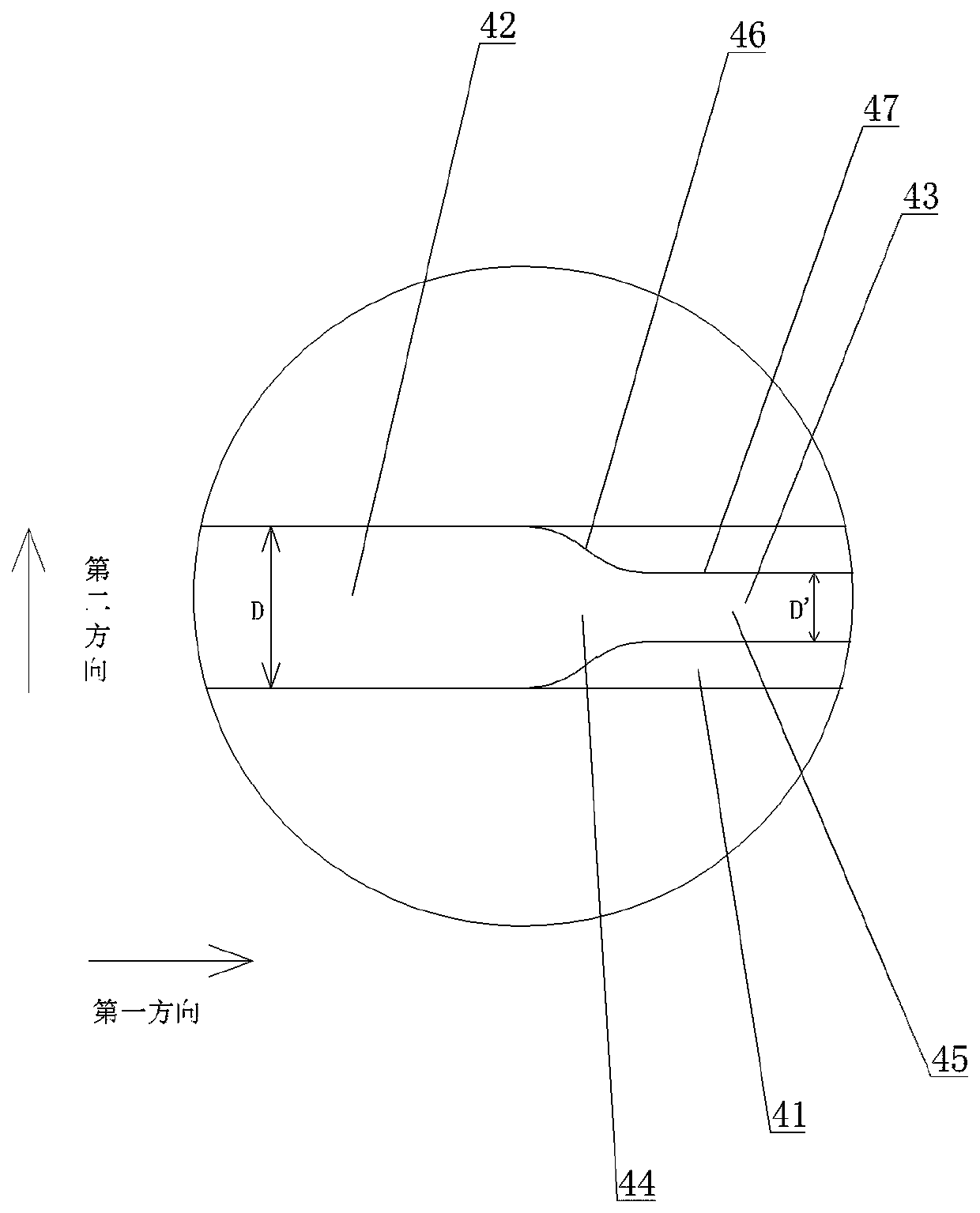

[0048] Embodiment 2: as Figure 4 As shown, the first cantilever segment conductive layer 43 has a symmetrical structure, which can make the heat change at both ends of the narrowed first cantilever segment conductive layer 43 equal, so that the degree of stiffness gradient is equal, thereby ensuring the stability of the overall structure. The width from the second cantilever segment conductive layer to the first cantilever segment conductive layer 43 gradually decreases, and the cross-sectional width of the first cantilever segment conductive layer 43 gradually decreases from the two ends to the middle in the first direction on both sides, The first cantilever segment conductive layer 43 includes tapered portions 48 at both ends and a straight line portion 45 in the middle, the tapered portions are respectively connected to the second cantilever segment conductive layer and the straight portion 45, and the tapered portion The two opposite sides in the first direction are stra...

Embodiment 3

[0050] Embodiment 3: as Figure 5 As shown, in this embodiment, the cross-sectional width of the conductive layer 43 of the first cantilever segment gradually decreases from the two ends to the middle along the lower side in the first direction, and the upper side remains unchanged and is concave inward. The conductive layer 43 of the first cantilever segment includes arc-shaped portions 44 located at two ends and a straight line portion 45 located in the middle. The lower side of the arc portion 44 in the first direction is an arc segment 46, the upper side is a straight line segment, and the upper side is flush with the upper side of the conductive layer of the second cantilever section. The straight line portion 45 On both sides in the first direction are straight line segments 47 . It can also be adopted that the cross-sectional width of the first cantilever segment conductive layer 43 gradually decreases from the two ends to the middle in the first direction, and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com