A microfiber functionalized filter rod tow with functions of carrying fragrance and selectively reducing phenol content in smoke, and its preparation and application

An ultra-fine fiber and selective technology, applied in applications, e-liquid filter elements, tobacco, etc., can solve the problems of harm reduction, increase the production process and cost, and poor selectivity, so as to reduce the release of phenol and highlight the effect of selectivity reduction , the effect of unique fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

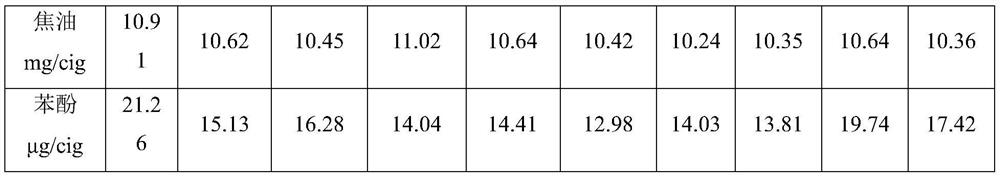

Examples

Embodiment 1

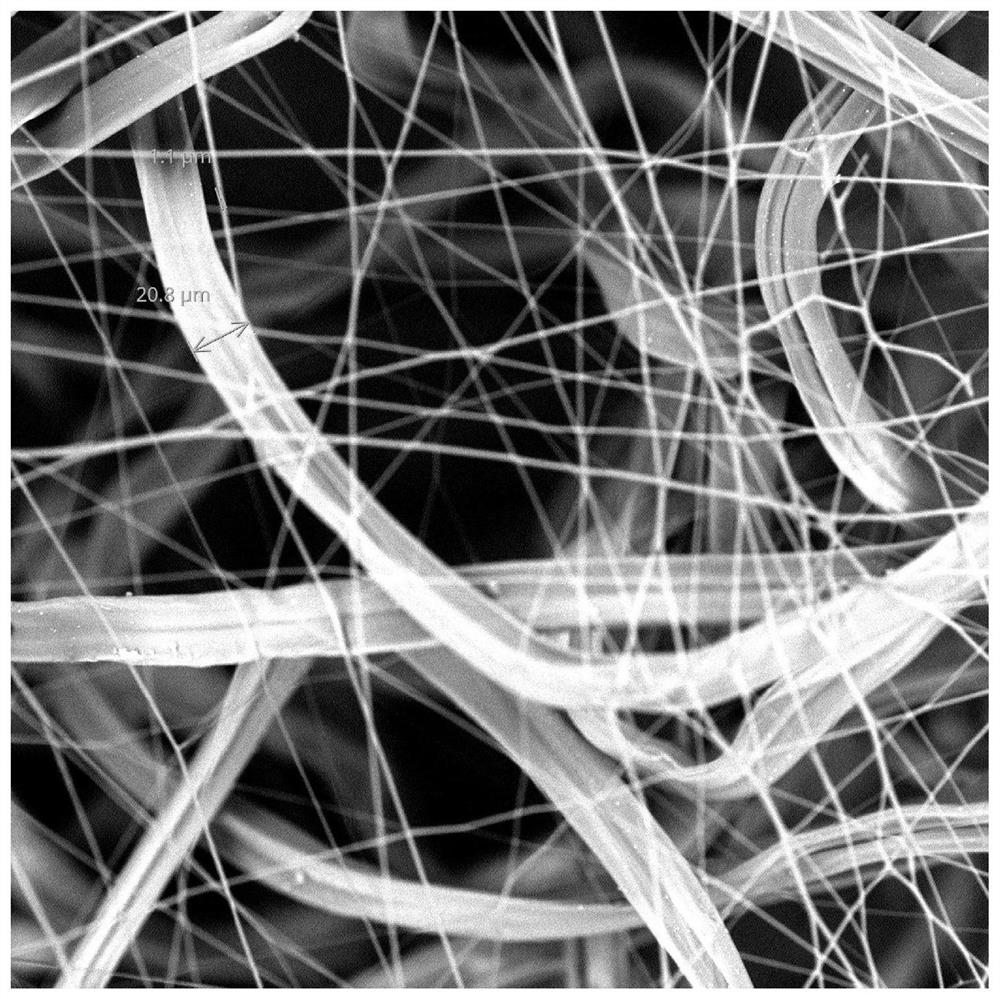

[0040] Preparation of electrospun microfiber functional tow with fragrance carrying ability

[0041] Electrospinning is performed in an electrospinning chamber. Mix polyvinylpyrrolidone K30 and smoked extract at a mass ratio of 80:20 to form a spinnable fabric, then mix the spinnable fabric with solvent water at a mass ratio of 15:85, and continuously stir for 5 hours in a constant temperature water bath at 50°C to obtain The uniform spinnable solution is placed in the storage tank, and the material liquid is supplied to 80 electrospinning nozzles at a speed of 3mL / h through a micropump. The electrospinning voltage is 15KV, and the distance between the nozzle and the paper base is 10cm , the electrospinning ambient temperature is 28°C, each group of electrospinning nozzles has 20 nozzles, each group of nozzles forms a circuit, and each group of nozzles rotates continuously in the circuit at a constant speed, so that the electrospinning is uniform on the receiving substrate. O...

Embodiment 2

[0045] Preparation of electrospun microfiber functional tow with fragrance carrying ability

[0046] Electrospinning was performed in the electrospinning chamber in Example 1. The spinning equipment is the same as in Example 1.

[0047] Mix polyvinylpyrrolidone K60 and smoked extract at a mass ratio of 70:30 to form a spinnable fabric, then mix the spinnable fabric with solvent water at a mass ratio of 15:85, and continuously stir for 5 hours in a constant temperature water bath at 50°C to obtain Uniform spinnable solution, at room temperature, using 20KV voltage and 10cm receiving distance, spinning solution advancing speed 3ml / h, on the tow to prepare ultra-fine fibers with a diameter of about 940nm with fragrance-carrying ability, ultra-fine fibers on the silk The amount of spraying on the beam substrate is about 1.0g / m 2 ..

[0048] Functional tow filter rod and cigarette preparation and smoke analysis:

[0049] Replace the original tow on the filter rod forming machin...

Embodiment 3

[0051] Preparation of electrospun microfiber functional tow with fragrance carrying ability

[0052] Electrospinning was performed in the electrospinning chamber in Example 1. The spinning equipment is the same as in Example 1.

[0053] Mix polyvinylpyrrolidone K90 and green tea extract at a mass ratio of 60:40 to form a spinnable fabric, then mix the spinnable fabric with solvent water at a mass ratio of 20:80, and stir continuously for 5 hours in a constant temperature water bath at 50°C to obtain a uniform Spinnable solution, at room temperature, using 25KV voltage and 15cm receiving distance, spinning solution advancing speed 3.2ml / h, on the tow to prepare ultra-fine fibers with a diameter of about 800nm with fragrance-carrying ability, the ultra-fine fibers are on the silk The amount of spraying on the bundle substrate is about 1.2g / m 2 ..

[0054] Functional tow filter rod and cigarette preparation and smoke analysis:

[0055] Replace the original tow on the filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com