Material for preparing hydrophilic micro-fluidic chip, and micro-fluidic chip

A microfluidic chip and hydrophilic technology, which is applied in the direction of laboratory containers, laboratory utensils, chemical instruments and methods, etc., can solve the problems of easy peeling off of the coating, rapid processing regression, and limited application, etc., to achieve Reduce time and process costs, reduce non-specific adsorption, and reduce the effect of non-specific adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

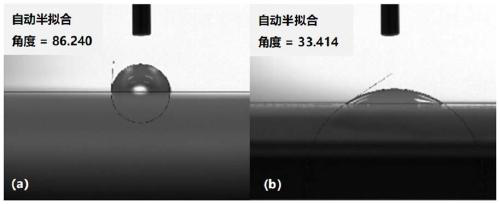

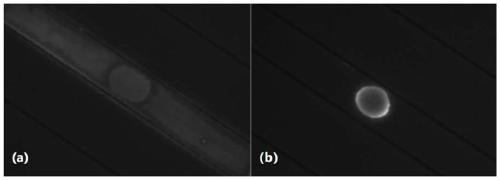

Method used

Image

Examples

Embodiment 1

[0028] Take 100 parts of dry rubber, 1 part of hydrophilic additive, 2 parts of color masterbatch, mix them evenly, pour them into the injection molding machine, set the injection molding parameters as follows: nozzle temperature 230°C, injection speed 100mm / s, mold temperature 70°C, keep The pressing pressure is 65MPa, the holding time is 2s, and the microfluidic chip mold is used together to prepare a hydrophilic microfluidic chip.

[0029] The sizing material used in this embodiment is polymethyl methacrylate (PMMA); the hydrophilic auxiliary agent is polyvinyl alcohol.

Embodiment 2

[0031] Take 100 parts of dry rubber, 0.1 part of hydrophilic additive, 1 part of color masterbatch, mix well, pour into the injection molding machine, set the injection molding parameters as follows: nozzle temperature 230°C, injection speed 100mm / s, mold temperature 70°C, keep The pressing pressure is 65MPa, the holding time is 2s, and the microfluidic chip mold is used together to prepare a hydrophilic microfluidic chip.

[0032] The sizing material used in this embodiment is polymethyl methacrylate (PMMA); the hydrophilic auxiliary agent is polyacrylic acid.

Embodiment 3

[0034] Take 100 parts of dry rubber, 5 parts of hydrophilic additives, and 5 parts of color masterbatch, mix them evenly, pour them into the injection molding machine, set the injection molding parameters as follows: nozzle temperature 230°C, injection speed 100mm / s, mold temperature 70°C, keep The pressing pressure is 65MPa, the holding time is 2s, and the microfluidic chip mold is used together to prepare a hydrophilic microfluidic chip.

[0035] The rubber material used in this embodiment is polydimethylsiloxane (PDMS); the hydrophilic auxiliary agent is polyvinylpyrrolidone.

[0036] The present invention also prepares hydrophilic microfluidic chips prepared from other raw materials, and the specific raw material ratios are shown in Table 1.

[0037] Table 1 is used to prepare the raw material proportion (parts by weight) of hydrophilic microfluidic chip

[0038] Sample / raw material Gum Hydrophilic additive masterbatch sample 1 100 0.5 2 sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com