Synergistic curing treatment method of electrolytic manganese residues and phosphogypsum waste residues

A technology of electrolytic manganese slag and solidification treatment, which is applied in chemical instruments and methods, solid waste removal, transportation and packaging, and can solve the problems of insufficient compressive strength, volume change, large proportion of dihydrate gypsum, and increased production costs. , to achieve the effect of increasing the unconfined compressive strength and softening coefficient, enhancing the compressive strength and softening coefficient, and solving the problem of land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

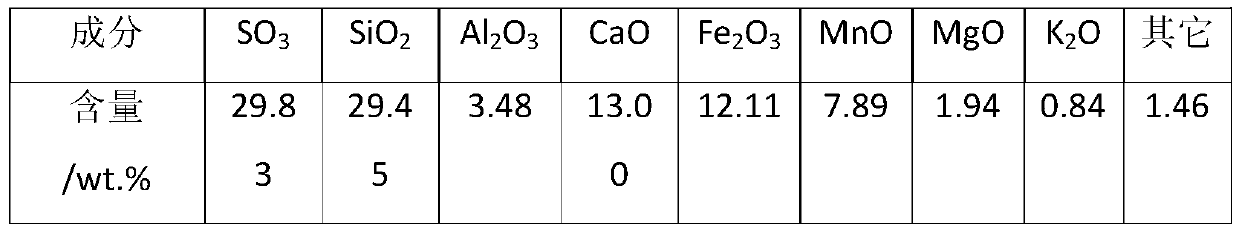

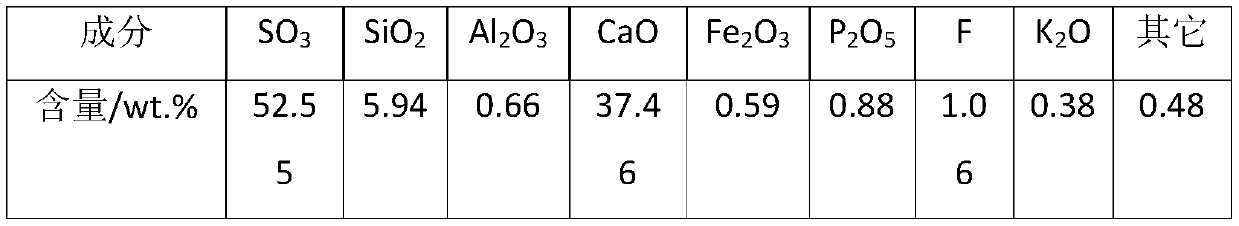

[0041] In this embodiment, electrolytic manganese slag from a manganese ore dressing field in Guangxi Zhuang Autonomous Region and phosphogypsum waste slag from a certain phosphogypsum storage yard in Hubei were collected as solidification raw materials, wherein the chemical compositions of electrolytic manganese slag and phosphogypsum are shown in Table 1 and Table 2:

[0042] Table 1 Chemical composition analysis (XRF) of electrolytic manganese slag

[0043]

[0044] Table 2 Chemical composition analysis (XRF) of phosphogypsum

[0045]

Embodiment 2

[0047] A method for synergistically solidifying electrolytic manganese slag and phosphogypsum waste slag, the method comprising the following steps:

[0048] (1) Air-dry the electrolytic manganese slag and phosphogypsum until the moisture content of the two is less than 19%, and use a jaw crusher to crush the air-dried electrolytic manganese slag and phosphogypsum to a particle size of less than 2.5mm; after testing, electrolytic manganese The moisture content of slag is 12.09%, and the moisture content of phosphogypsum is 18.04%;

[0049] (2) According to the proportioning of materials, take by weighing 767.8g of electrolytic manganese slag in embodiment 1 and the phosphorite waste residue in 919.0g of embodiment 1, carry out uniform stirring;

[0050] (3) Take by weighing 186.1g tap water and add in the mixed material by electrolytic manganese slag and phosphogypsum, carry out uniform stirring;

[0051] (4) After the stirring is finished, weigh 75.0g curing agent and add it...

Embodiment 3

[0061] A method for synergistically solidifying electrolytic manganese slag and phosphogypsum waste slag, the method comprising the following steps:

[0062] (1) Air-dry the electrolytic manganese slag and phosphogypsum until the moisture content of the two is less than 18%, and use a jaw crusher to crush the air-dried electrolytic manganese slag and phosphogypsum to a particle size of less than 2.5mm; after testing, electrolytic manganese The moisture content of slag is 12.09%, and the moisture content of phosphogypsum is 18.04%;

[0063] (2) According to the proportioning of materials, take by weighing 1109.0g of the electrolytic manganese slag in the embodiment 1 and the phosphogypsum in the 551.5g of the embodiment 1, and carry out uniform stirring;

[0064] (3) Take by weighing 187.5g tap water and add in the mixing material by electrolytic manganese slag and phosphogypsum, carry out uniform stirring;

[0065] (4) After the stirring is finished, weigh 75.0g of curing age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com